The Sudanese customer requested the new gold mining CIL concentrator to design 500t/d. The Nile concentrator learned that the gold content of this project is 3.9 g/t. The raw ore supply particle size is 500 mm. Therefore, according to the actual needs of customers, Nile mineral processing engineers designed a complete daily production capacity of gold leaching CIP production line design.

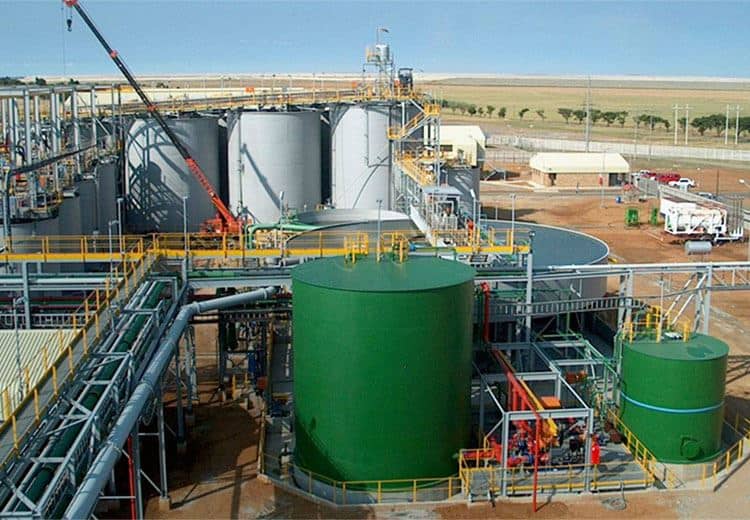

500TPD Gold Mining Processing Plant Site:

Note: If you need to design a small-scale gold processing plant or a large-scale commercial gold processing plant, Please Email: info@nile.ltd. Whatsapp/Wechat/Phone: 008618530968358 The Nile Processing Design Team. Access to high-efficiency beneficiation equipment with commercial value.

500TPD Gold Mining and Processing Plant Design Details

1. Crushing and Screening of Raw Ore:

The maximum particle size of raw ore feeding is 500mm. The design scale is 500 tons/day. According to the nature of the ore, the crushing equipment is coarse crushing Jaw Crusher- medium crushing Symons Cone Crusher- fine crushing Symons Cone Crusher. The three stages of crushing are closed, and the particle size of crushing is -12mm.

The above selection of stone crusher and crushing ore process has the following advantages:

1. The crusher is highly reliable. Facility infrastructure is small, and the plant area is small, and the infrastructure investment is small;

2. The production equipment is easy to operate and maintain, with low energy consumption and low production and operation costs.

|  |

2. Grinding and Classification

1The design of the grinding process and the selection of equipment have a significant impact on the investment, cost and profit recovery of commercial beneficiation. In energy saving, minimize environmental pollution, easy to manage and maintain. Therefore, the Nile beneficiation team adopts 2 stages and 2 closed-circuit continuous grinding process: 1-stage closed-circuit grinding adopts two ×4500 overflow sub-type ball mills and two spiral classifiers.

The main equipment of the 2-stage closed-circuit grinding is an Overflow Ball Mill and a Hydro-cyclone.

|  |

3. Gravity Separation Method

Gravity beneficiation method is used to recover granular gold: the main equipment used is 6S Gold Mining Shaking Table and Centrifugal Concentrator Gold.

|  |

4. Carbon Leaching-Adsorption

High-efficiency Thickener and Ming Leaching Tank are used for concentration of gold ore before leaching

|  |

5. Tailings Filter Press

The leaching residue is dewatered by Filter Press.

|

Gold Mining Processing Design Factory - The Nile Machinery

Mineral processing customers often send us emails through the website mailbox to inquire about the design price of mineral processing equipment and mineral processing. Within the time of receiving the customer's email. The mineral processing technology professional will communicate with the customer the actual needs, useful minerals, gangue minerals, ore hardness and density, processing capacity and output, raw ore grade, gold ore grade and recovery rate and other details . Of course, it also contains the qualification documents of our company. Nile contemporaries are very patient and will help customers to solve all problems. So don't worry about communication issues.

Mineral processing customers often send us emails through the website mailbox to inquire about the design price of mineral processing equipment and mineral processing. Within the time of receiving the customer's email. The mineral processing technology professional will communicate with the customer the actual needs, useful minerals, gangue minerals, ore hardness and density, processing capacity and output, raw ore grade, gold ore grade and recovery rate and other details . Of course, it also contains the qualification documents of our company. Nile contemporaries are very patient and will help customers to solve all problems. So don't worry about communication issues.

Mineral processing equipment will be shipped according to the date agreed by the customer. In order to ensure that the customer can start the mineral processing project as soon as possible after receiving the mineral processing equipment. yield recovery. If you have mineral processing projects or mineral processing equipment. Please Email: info@nile.ltd. Whatsapp/Wechat/Phone: 008618530968358. Design cost-effective ore processing plants according to different ore types. Nile is a beneficiation equipment manufacturer responsible for design, production, installation, sales and after-sales, so we have no middleman prices and are shipped directly from the factory.