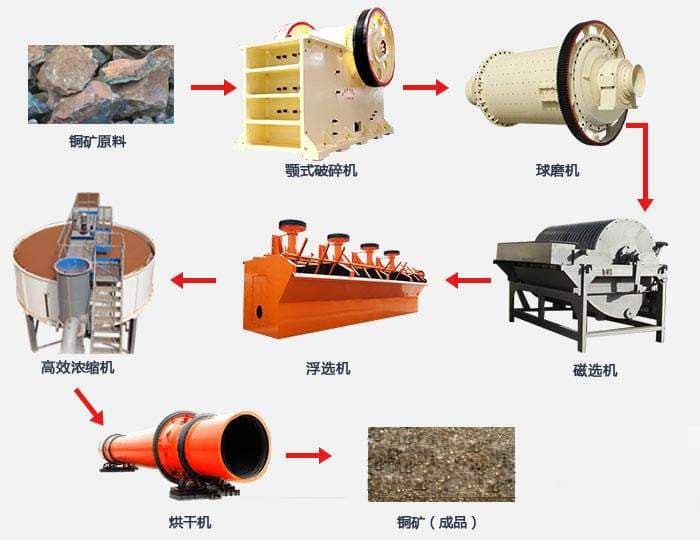

The Nile received a 500TPD scale copper mining processing from Zambian customer, and our beneficiation team needed to provide the design and cost of the entire copper mine processing production line. Therefore, our beneficiation project takes into account the constraints of energy and environmental protection, and the final design plan for copper ore processing is: the refined copper concentrate has a grade of 20%.

The main equipment used for 500TPD copper ore processing are Vibrating Feeder, Jaw Crusher, Fine Jaw Crusher, Overflow Ball Mill and Flotation machine.

Ore Dressing Plant For Sale, please Email: info@nile.ltd. Whatsapp/Wechat/Phone: 008618530968358

Process Design of 500TPD Copper Mining Processing Plant

1. Copper Mineral Processing

1) According to the nature of the ore, the crushing adopts a two-stage closed-circuit process. The crushing process is formulated mainly based on: the maximum feeding force of the raw ore, the particle size of the raw ore, the physical properties of the raw ore, the water content and the mud content of the raw ore, etc.

2) Different types of stone crushers have different performances. According to the crushing ratio required by customers, our mineral processing engineer recommends Jaw Crusher and fine crushing Jaw Crusher.

2. Grinding and Flotation

1) 1) The design grinding is for the first stage grinding with a feeding force of 25mm and a discharge force of 0.15mm. The grinding equipment Overflow Ball Mill

2) Most copper ores need to be sorted, and Flotation is the main method for sorting copper ores. also. Gravity Beneficiation and Magnetic Separation also have applications.

Copper Processing Plant For Sale - The Nile

Small, neutral, and large-scale mineral processing plant design. There are many concentrators. Compared with other concentrators, Nile Machinery has independent branches and warehouses in Kenya and Sudan. If you have already purchased our mine crushing equipment or mineral processing equipment, you will know our company very well, and you will go through two more purchases. It can be seen that our machinery and equipment have great potential competitiveness in terms of price and after-sales service.

The construction of a concentrator is a systematic project, especially in the field of economic benefits, with the aim of improving economic profits. If you have mineral processing projects or mineral processing equipment, please Email: info@nile.ltd. Whatsapp/Wechat/Phone: 008618530968358