The Philippine customer first sent us a photo of the copper ore to be processed. Our mineral processing engineer identified and concluded the characteristics of the copper ore: Scattered inlaid among the quartz and calcite particles. The raw ore contains less mud, the ore is compact, hard and wear-resistant, and the sulfur and iron are relatively low. The water content of the ore is 3%, and the density is 2.33-2.66/cm. According to the recovery rate of copper concentrate requested by the customer at 95.97%, the two parties have determined that the copper ore processing method is the flotation beneficiation process in the process of continuous communication. The following is the feasibility of flotation copper mine establishment given by our engineer.

2. Process Flow and Equipment Selection of Copper Processing

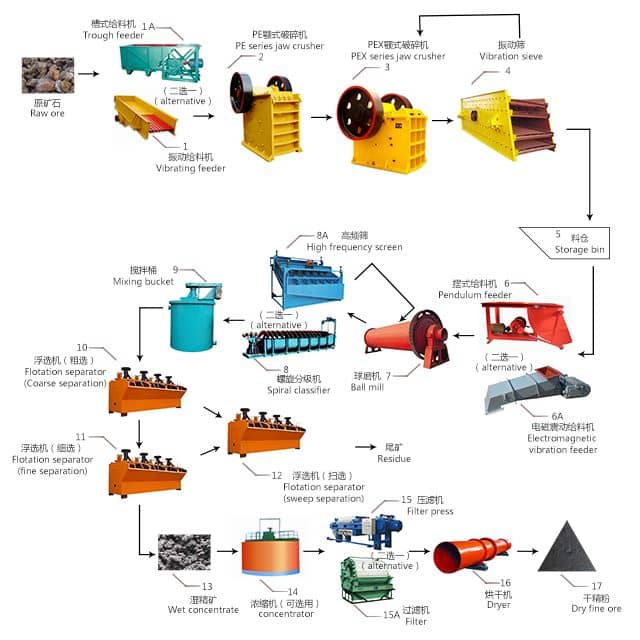

After years of beneficiation experience by our engineers, the main recycled metal in this design is copper. According to the nature of the ore, considering that the silica content in the raw ore is as high as 75%, the ore is relatively hard and difficult to grind. Therefore, the copper processing process is designed as:

(1) Copper mine crushing: adopt three-stage one-closed-circuit process

(2) Grinding: one-stage grinding and spiral classifier; two-stage grinding and hydrocyclone; the final product is 80%-200 mesh feeding flotation operation.

(3)Concentrate dewatering: The thickener and filter for concentrate dewatering are used to realize the self-flow of concentrate pulp.

Design small, neutral and large mineral beneficiation processes, contact: Whatsapp/Wechat:008618530968358

3. Copper Beneficiation Results

Since the copper mine was put into production, the stage grinding and stage selection process of this beneficiation design has been followed. Practice has also proved that it is reasonable to use copper flotation processing process to treat copper-bearing sulfide ore in quartzite sandstone. There is economic value, the grade of raw ore is 1.02%, the grade of concentrate is 22.98%, and the recovery rate is as high as 96.47%.

4. Copper Processing Factory -The Nile Mineral Beneficiation Processing Manufacturer

The variety of copper mine processing equipment produced by The Nile is suitable for customers of different scales and types. But efficient beneficiation equipment models can really bring you economic benefits and value. Furthermore, as a manufacturer, we have a good understanding of the beneficiation equipment and technologies we produce. We can guarantee the high quality and longevity of our equipment. We also have a professional after-sales service maintenance team, if there is a problem with our mineral processing equipment, they will let customers know in time. In addition, we also design gold leaching production line, gravity beneficiation production line, magnetic separation production line. If you need production lines for processing gold, copper or tailings, please feel free to contact us for the most competitive price【Emai: info@nile.ltd, Whatsapp/Wechat/Phone: 008618530968358】