CIL Gold Processing Plant For Sale

Tanzania 1500t/d gold beneficiation production line Design, Manufacture, Installation, After-sales. The raw ore has a gold content of 1.79g/t, of which gold is the only element with economic value. Using the oxidation leaching process, the leaching rate and adsorption rate reached 93% and 98.0. The gold leaching and beneficiation process has a higher recovery rate of gold than other types of beneficiation processes, avoiding the waste of gold in the beneficiation process.

Gold CIL Plant For Sale, Contact Infontation: Whatsapp/Wechat/Phone:008618530968358

1. Gold Extraction Methods From Ore?

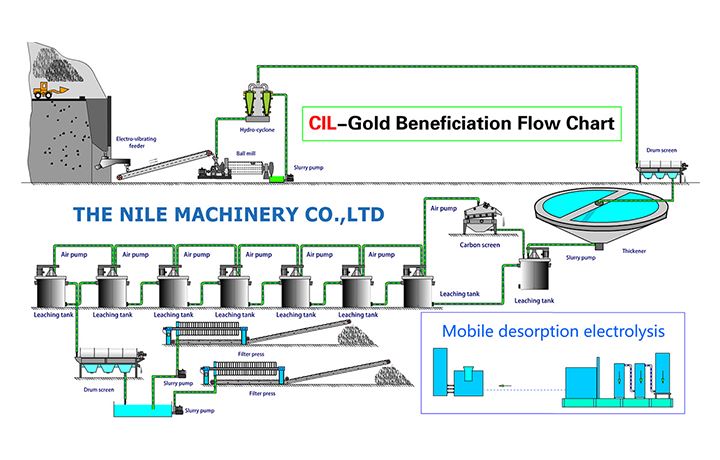

According to the properties of raw ore and Nile beneficiation experience, the design process flow is: crushing and screening - grinding and classification - carbon leaching, adsorption - tailings pressure filtration. In order to determine the efficient value, improve the process flow. Nile has undertaken the entire production process design of the cip gold processing plant.

Gold CIL Plant Design Process:

(1) Crushing and screening: Based on the principle of more crushing and less grinding, three-stage one-closed-circuit crushing process is adopted, and the crushing particle size is -12mm;

(2) Grinding and classification: The two-stage two-closed-circuit continuous grinding process is adopted. The final grinding fineness-200 mesh accounts for 90%.

(3) Carbon leaching and adsorption: adopt the whole mud cyanidation-carbon slurry adsorption process. The overflow of the thickener before leaching is adsorbed by a two-stage carbon adsorption column, and the gold grade of the gold-loaded carbon is 2000g/t.

(4) Pressure filtration of tailings: The leaching slag adopts the process of pressure filtration and dehydration, and the filter cake is transported to the tailings pond for centralized storage. The tailings contain 20% water, and the lean liquid flows back to the carbon pulp plant for recycling.

2. Cyanide Leaching Process--CIL Gold Processing Plant--Gold Leaching Process

The above is a large-scale 1500t/d gold oxide leaching process configured by our Nile Concentrator in Tanzania, with a recovery rate of over 93%. As a mineral processing production line design and mineral processing equipment manufacturer for many years, we configure the most ideal equipment selection for our customers, aiming to improve the gold recovery rate. In addition to the process of gold extraction by oxidation, the Nile Concentrator also has CIP gold beneficiation, gravity beneficiation, flotation beneficiation, magnetic beneficiation, combined process design of magnetic separation and gravity beneficiation. Whether it's small, large or medium-scale beneficiation, The Nile takes every customer seriously. Of course, we also have beneficiation methods with different budgets. If you have a demand for our beneficiation equipment or a beneficiation project, please Email: info@nile.ltd immediately for our beneficiation technology consultation. Contact Whatsapp/Wechat/Phone: 008618530968358.