Products

Home > Products > Mineral Processing Equipment > Spiral Chute

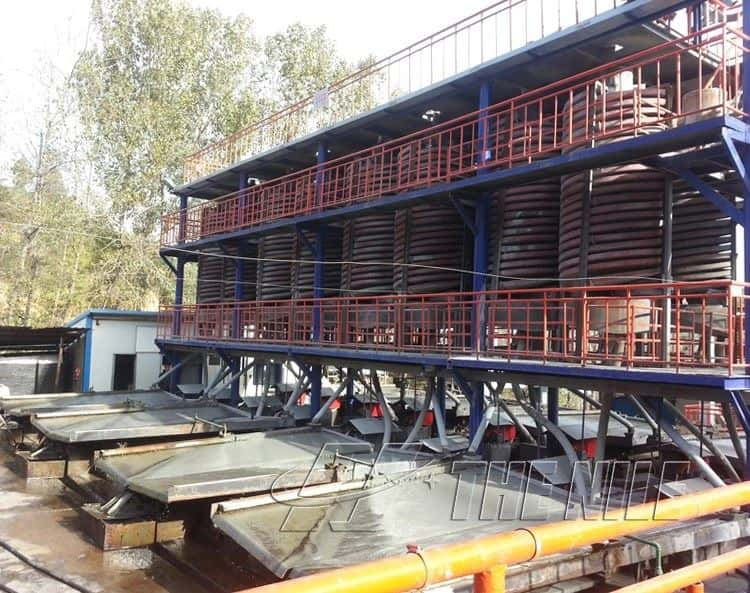

Processing Materials: Gravity separator spiral chute is mainly used for processing tungsten ore, niobium ore, tin ore, tantalum ore, non-ferrous metals, rare metals, and non-metallic mineral bodies with different specific gravity. Gravity separator spiral chute is more ideal for sand mining in the seashore, riverside, sand beach and stream.

Design Principle of Gravity Separator Spiral Chute

The shape of the gravity separator spiral chute is similar to the thread shape. The movement of the materials inside the spiral chute can be divided into three stages, which are the material introduction stage, material acceleration stage, and material uniform velocity warehouse stage. And the third stage has the longest last time, which is the key to materials crushing.

The key to the design of the gravity separator spiral chute is in the uniform velocity stage. The main parameters of machines are radius R, bottom plate width b, elevation height h, helix angle mouth, and bottom plate radial inclination angle.

The parameter selection of the spiral chute should be calculated according to the conditions of the warehouse, particle size, moisture, the number of materials.

Outstanding Advantages of Gravity Separator Spiral Chute

1. Small footprint and large processing capacity

It has characteristics of reasonable structure, simple installation, simple and reliable operation, small floor space, stable ore dressing, clear mineralization, large processing capacity, high efficiency, enrichment ratio, and recovery rate.

2.Easy to operate with high adaptation

Gravity separator spiral chute is not critical to the operation requirements (such as grain size, mass fraction, etc.). Even if the ore supply, ore concentration, ore size, and ore grade change, there is almost no influence on the selection index, which means that it has strong adaptability.

3.Good processing effect

The gravity separator spiral chute is not only easy to operate but also achieves a good treatment effect. It is characterized by stable and clear ore beneficiation, large processing capacity.

Technical Parameters of Gravity Separator Spiral Chute

Model | Outside diameter | Pitch of screw | Feed size | Capacity | Mine density | Area | Height |

DL400 | 400 | 180 | 0.02-0.2 | 0.2-0.5 | 30-50 | 0.25 | 1.5 |

DL600 | 600 | 390/360 | 0.02-0.2 | 0.8-1.2 | 30-50 | 0.5 | 2.6 |

DL900 | 900 | 540/360 | 0.03-0.3 | 2-3 | 30-50 | 1.2 | 4 |

DL1200 | 200 | 720/540 | 0.03-0.3 | 4-6 | 30-50 | 2 | 5.23 |

DL1500 | 1500 | 900 | 0.03-0.3 | 6-8 | 20-45 | 4 | 5.23 |

DL2000 | 2000 | 1200 | 0.04-0.4 | 7-10 | 20-45 | 5.7 | 5.23 |