Products

Home > Products > Mineral Processing Equipment > Spiral Chute

Processing Materials: Gravity chutes are suitable for separating iron ore, ilmenite, chromite, pyrite, zircon, rutile, phosphorite, etc. with a particle size of 0.3-0.02 mm fine materials. It is a new type of beneficiation equipment that combines the advantages of a spiral concentrator, shaking table, and centrifugal concentrator.

Introduction of Gravity Chutes

Gravity chutes belong to the slope flow separation process. The slurry is fed to a certainly inclined chute or inclined plane. Under the driving of water flow, the ore particles are loose and layered. The light minerals in the upper layer are quickly discharged out of the tank, while the heavy minerals in the lower layer are retained in the tank or discharged from the lower part at a low speed. After the separation of gravity chutes, the concentrate and tailings are obtained.

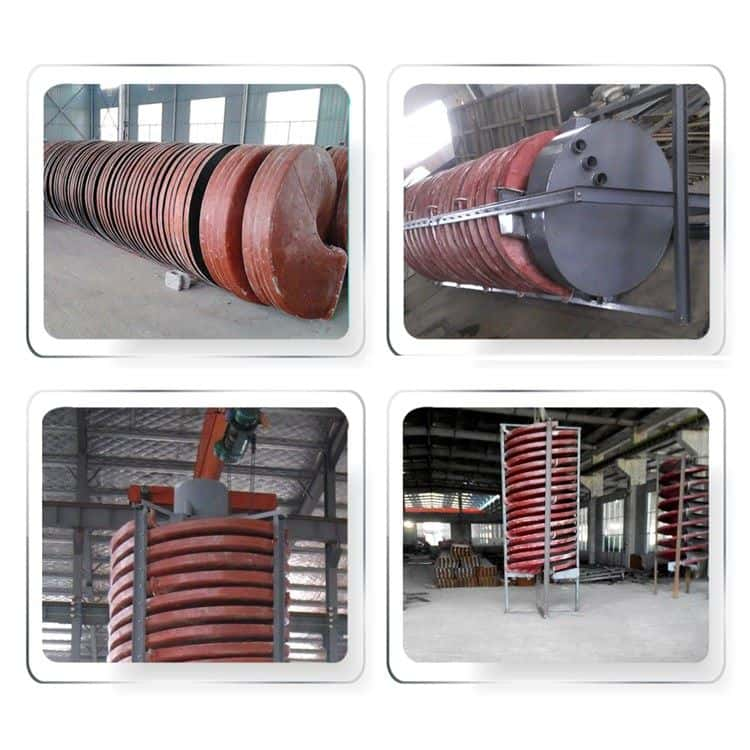

Basic Structure of Gravity Chutes

The main part of the gravity chutes device is the spiral flight which is made of glass fiber reinforced plastic. The inner surface of the spiral groove is coated with wear-resistant lining material, which usually a polyurethane wear-resistant glue or an epoxy resin mixed with artificial gold steel sand.

There are a mining machine and a feed tank in the upper part of the gravity chute and a product interceptor and a collecting tank in the lower part. The entire spiral chute equipment is framed vertically with steel frames.

The working characteristics of the gravity chute are that the fine powder, medium, and tailings are respectively taken at the end of the tank, and no washing water is added during the separation process.

Technical Parameters of Gravity Chutes

Model | Outside diameter | Pitch of screw | Feed size | Capacity | Mine density | Area | Height |

DL400 | 400 | 180 | 0.02-0.2 | 0.2-0.5 | 30-50 | 0.25 | 1.5 |

DL600 | 600 | 390/360 | 0.02-0.2 | 0.8-1.2 | 30-50 | 0.5 | 2.6 |

DL900 | 900 | 540/360 | 0.03-0.3 | 2-3 | 30-50 | 1.2 | 4 |

DL1200 | 200 | 720/540 | 0.03-0.3 | 4-6 | 30-50 | 2 | 5.23 |

DL1500 | 1500 | 900 | 0.03-0.3 | 6-8 | 20-45 | 4 | 5.23 |

DL2000 | 2000 | 1200 | 0.04-0.4 | 7-10 | 20-45 | 5.7 | 5.23 |