The 6-S shaker table is gravity beneficiation equipment used to separate fine-grained materials. It can be used for sweeping, roughing, and beneficiating operations of coarse and fine sand.

Product description

6-S shaker table, also known as a gold shaker and beneficiation shaker, is a gravity concentrator used to separate fine-grained materials. It is widely used to separate gold, silver, lead, tungsten, manganese, iron, etc., with large processing capacity and recovery with multiple advantages such as high efficiency and low energy consumption, the products are deeply loved by African users.

The working principle of the shaking table

The 6-S gold shaking table sways longitudinally back and forth, using a slow forward stroke and a fast return stroke to make the particles grow along the deck parallel to the direction of movement. The lighter material moves up and down on the shallows and is discharged from the tailings side of the workbench. Washing water is supplied from the top of the workbench at right angles to the direction of movement of the workbench. These forces combine to move the particles diagonally across the deck from the feed end and separate on the workbench according to size and density. Workbenches are most commonly used to recover gold from hard rock ore, but can also be used to recover other mineral materials with higher than normal densities. Even at relatively high feed rates, they can excellently recover small gold particles.

Features of 6-S gold shaking table

1. The proportion of high-grade ore is large, the sorting efficiency is high, the operation is convenient, and the stroke adjustment is convenient.

2. Long service life. The working surface of the 6-S gold ore vibrating table

is made of wear-resistant material with strong wear resistance and the product is not easily damaged.

3. Low maintenance cost. There are few wearing parts, the deck is resistant to chemical corrosion, acid, and alkali, solid and reliable, and hardly needs maintenance.

4. Wide application range. It can be used for the sorting of various rare metals and precious metal ores and has strong resistance to harsh environments.

5. No reagent consumption, high work efficiency, clean sorting, and low power consumption.

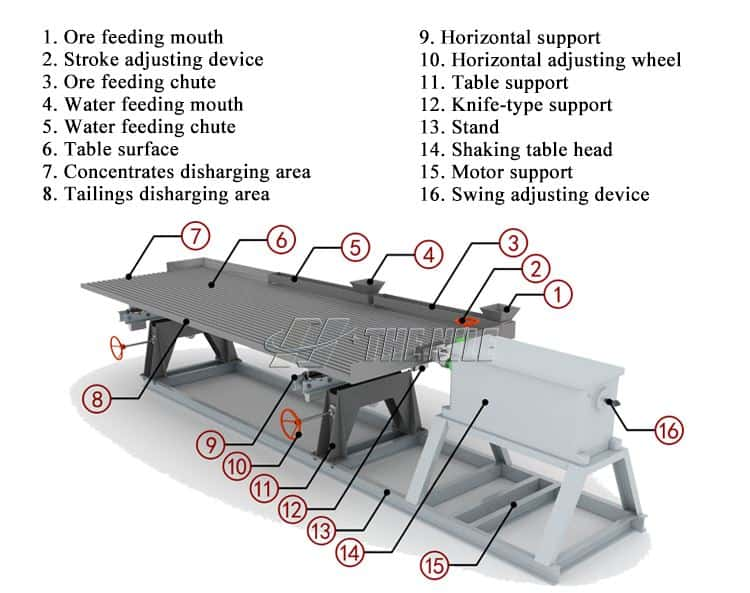

The structure of the 6-S gold shaker table

The main components include machine head, motor, slope adjuster, mine tank, water tank, composite strip, and lubrication system.

Packaging and shipping

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

pre-sale service:

(1) Professional technicians provide customers with suggestions for model selection.

(2) Design and manufacture machines according to customers' special requirements.

After-sales service:

(1)) Arrange technicians to guide the installation

(2) If your machine is out of warranty, you can buy spare parts from us at the best price.

(3) Engineers can repair machines overseas

No more→

| Model NO. | 6-S | Table Size | 4520*1850*150mm | |

| Stroke | 8-36mm | Motor Power | 1.1kw | |

| Time/min | 240-380 | Dimension | 5630*1850*900mm | |

| Landscape | 0-5 | Table Weight | 650kg | |

| Material | Feeding Size | Mine Density | Flushing Water | Capacity(t/h) |

| Coarse Sand | 0.5-2mm | 10-30% | 0.5-3.5t/h | 1-2.5 |

| Fine Sand | 0.074-0.5mm | 0.8-1.2 | ||

| Ore Mud | 0.037-0.074mm | 0.3-0.6 | ||