Products

Home > Products > Mineral Processing Equipment > Shaking Table

Processing Materials: Concentrator table is the use mechanical shaking and water washing to separate ore particles according to their density, which is one of the most widely used gravity separation methods to separate fine-grained materials. It's mainly used for processing lead ore, iron ore, manganese ore, ferrotitanium, tin ore, tungsten ore, gold and silver ore, etc.

Technical Parameters ofConcentrator Table

Model NO. | 6S | Table Size | 4520*1850*156mm | |

Stroke | 8-36mm | Motor Power | 1.1kw | |

Time/min | 240-380 | Dimension | 5630*1850*900mm | |

Landscape | 0-5° | Table Weight | 650kg | |

Material | Feeding Size | Mine Density | Flushing Water | Capacity(t/h) |

Coarse Sand | 2-0.5mm | 10-30% | 0.5-3.5t/h | 1-2.5 |

Fine Sand | 0.5-0.074mm | 0.8-1.2 | ||

Ore Mud | 0.0774-0.037mm | 0.3-0.6 | ||

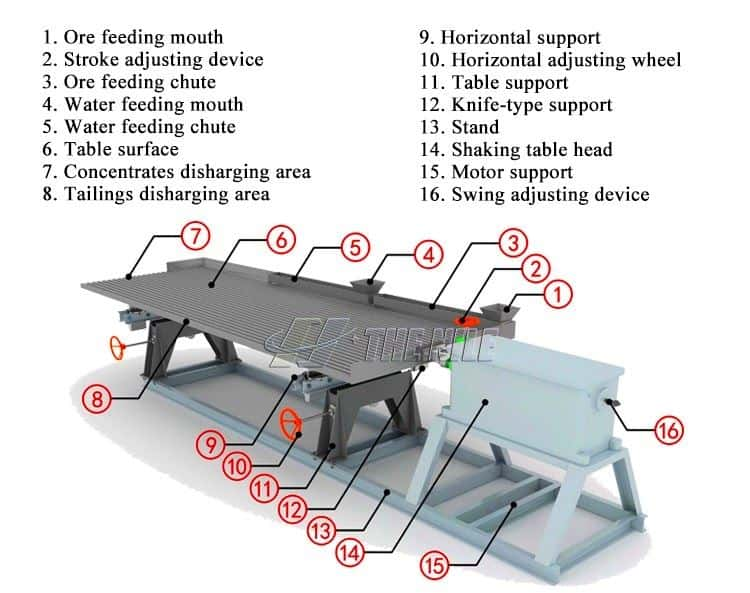

Working Principle of Concentrator Table

The washing water supplied by the feed water tank of the concentrator table is spread over the horizontally inclined bed surface and forms a uniform inclined thin layer water flow. When the material pulp with a concentration of 25% ~ 30% flows from the feeding trough to the bed surface, the ore particles will be loose and layered in the bed strip or groove under the action of water washing and bed surface vibration. The light mineral particles in the upper layer are subject to greater impulse, and most of them move downward along the bed surface to form tailings, which is called the tailings side. The heavy mineral particles at the bottom of the bed move along the longitudinal direction by the differential motion of the bed surface and are discharged from the opposite side of the driving end to form the concentrate, which is called the concentrate end.Different density and size of ore particles have different horizontal and vertical action on the bed surface, and the movement direction is different. The ore particles are fan-shaped on the bed surface, and a variety of products with different quality can be selected.

Advantages of Concentrator Table

1.Low material requirements. The upper limit of separation particle size of the concentrator table is 3 mm and the lower limit is 0.4 mm. It is mostly used to separate materials below 1 mm.

2.Easy to operate. The structure of the beneficiation shaking table is more complicated, the operation is not convenient, the productivity is also low, and it occupies a large plant area.

3.High concentrate rate. The salient feature of the concentrator table is its high rich ore ratio. It is often used to obtain concentrates, while at the same time it can separate tailings, which can effectively process fine-grained materials.

4.High safety performance. The concentrator table adopts a special safety system device, which can automatically protect the equipment. The low-speed operation structure makes the equipment run more smoothly.

Technical Parameters of Concentrator Table

Model NO. | 6S | Table Size | 4520*1850*156mm | |

Stroke | 8-36mm | Motor Power | 1.1kw | |

Time/min | 240-380 | Dimension | 5630*1850*900mm | |

Landscape | 0-5° | Table Weight | 650kg | |

Material | Feeding Size | Mine Density | Flushing Water | Capacity(t/h) |

Coarse Sand | 2-0.5mm | 10-30% | 0.5-3.5t/h | 1-2.5 |

Fine Sand | 0.5-0.074mm | 0.8-1.2 | ||

Ore Mud | 0.0774-0.037mm | 0.3-0.6 | ||