The 6-S shaker table machine is one of the commonly used gravity benefaction equipment. It can be used for sweeping, roughing, and benefaction operations. It has the advantages of compact structure, low energy consumption, and easy operation.

Product description:

The 6-S gold shaking table is a highly efficient and convenient shaker developed by our company based on user needs and technological development. From the initial straight surface to the hyperbolic wave surface shaker, the processing of the shaker is greatly improved. Quantity and recovery rate. The products are very popular among users and have been sold to many countries.

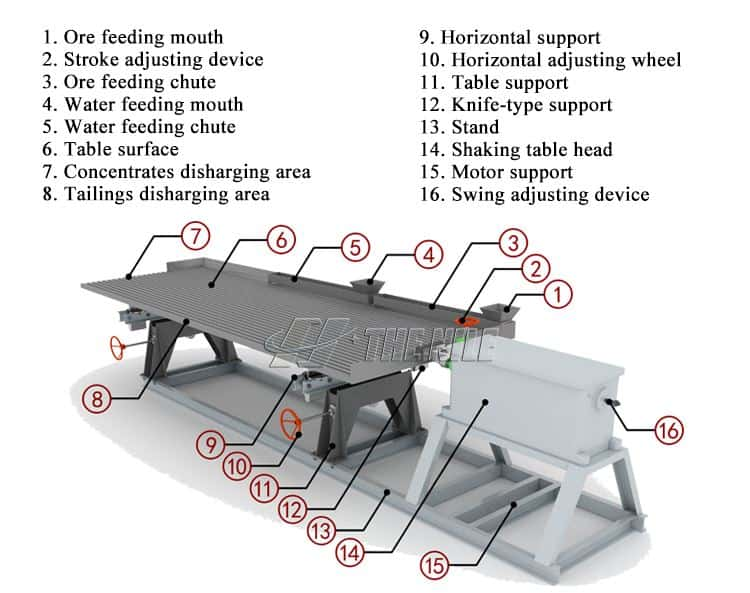

The components of the 6-S gold shaker machine:

The shaker is mainly composed of a bedhead, a motor, a slope regulator, a bed surface, a mining tank, a water tank, and a lubrication system. The bed surface is longitudinally reciprocated through a crank connecting rod transmission mechanism. The electric motor drives the rotary rocker to move up and down along with it through the belt drive. When the rocker moves down, the toggle plate pushes the rear axle and the reciprocating rod to move backward.

Features of 6-S shaking table for sale:

1. The horizontal slope adjustment range is large (0~10°), and the stroke is easy to adjust;

2. The 6-S gold ore vibrating table can also keep the bed surface running smoothly when changing the lateral slope and stroke;

3. The use of high-quality steel channel, strong wear resistance.

4. Wear-resistant coating is added to the surface of the vibrating table, which has a long service life.

5. There are few wearing parts, stable operation, and the product is not easy to be damaged.

Maintenance:

The 6-S gold shaker table machinery has stable performance in daily work. However, in actual production, due to the lack of correct maintenance methods and incorrect installation when replacing parts, some conventional problems are prone to occur. Most actual users of these problems lack inspection and maintenance experience, which affects the normal production of the concentration and causes unnecessary losses. Therefore, we must pay attention to the daily maintenance of the machine. When there is abnormal noise in the shaker, the operator should check the large pulley, swing lever, eccentric shaft, spring, toggle plate, and other components in time, and adopt corresponding solutions, as well as cause damage to the machine.

Overseas service:

1. We have engineers in Kenya, Sudan, and Uganda, they will provide professional installation and training skills.

2. We have factories and warehouses in Kenya and China. When your wearing parts are damaged, you can go directly to the factory to buy them, which is convenient and quick.

3. Our products have been distributed all over China and exported to Europe, America, Asia, and African countries. Our sales managers and engineers know the local situation very well, and we will provide you with the most suitable solution.

| Model NO. | 6-S | Table Size | 4520*1850*150mm | |

| Stroke | 8-36mm | Motor Power | 1.1kw | |

| Time/min | 240-380 | Dimension | 5630*1850*900mm | |

| Landscape | 0-5 | Table Weight | 650kg | |

| Material | Feeding Size | Mine Density | Flushing Water | Capacity(t/h) |

| Coarse Sand | 0.5-2mm | 10-30% | 0.5-3.5t/h | 1-2.5 |

| Fine Sand | 0.074-0.5mm | 0.8-1.2 | ||

| Ore Mud | 0.037-0.074mm | 0.3-0.6 | ||