Jaw crushers and impact crushers are commonly used crushing equipment in the mining industry. Most people think that there is no difference between the two. Only one of them is purchased in the selection of crushers, which results in the output not meeting the requirements. Today, I will give you a detailed introduction to the role and difference between the two in the broken line.

1. The role of jaw stone crusher and impact crusher

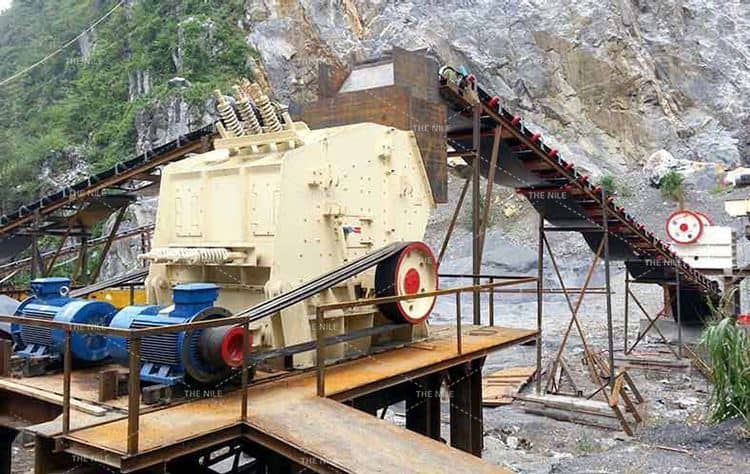

Jaw crushers and impact stone crushers are indispensable equipment in production lines such as crushing, sand making, and beneficiation. The lack of any equipment will affect subsequent production. If we want a production line, both the jaw crusher and the impact crusher must be purchased to form a complete production line.

2. The difference between jaw crusher and impact crusher machine

1. The working principle is different

The jaw crushing machine adopts the squeeze crushing principle, and the material is squeezed and crushed in the crushing cavity composed of the fixed cone and the movable cone. The impact crusher adopts the principle of impact crushing, and the material is repeatedly impacted and broken between the plate hammer and the impact plate.

2. The location of the production line is different

Jaw crusher is a commonly used primary crushing equipment for coarse crushing (fine jaw crusher can be used for medium or fine crushing), while impact crushing is a commonly used secondary or tertiary crushing equipment for medium or fine crushing.

3. Different requirements for the hardness of the material and the particle size of the feed

The jaw rock crusher can crush all soft and hard materials with compressive strength below 350 MPa, such as granite, basalt, etc. The ore with a particle size below 1.2 meters can be crushed with a jaw crusher. The impact crusher machinery has a small feed size and is mostly used to process some small and medium-sized materials. It is suitable for crushing medium-hard or brittle materials, such as limestone, limestone, etc.

4. Different production capacity

The capacity of the jaw crusher for mining is larger than that of the impact crusher. The maximum processing capacity of the jaw crusher can reach 1000 t/h, and the processing capacity is relatively large. The maximum processing capacity of the impact crusher is 350 t/h.

5. Different discharging grain types

After jaw stone crushing machine extrusion treatment, the material size is not ideal, and the pin content is large; the impact crushing equipment is the product with good output size and few edges and corners of the finished product, and its particle size is also better than that of cone crusher. In actual production, after the jaw crusher, a counterattack crusher is usually configured for further shaping, and the two are also a common combination in the crushing production line.

6. The price is different

The price of the jaw crusher equipment is relatively cheap, and it is traditional crushing equipment, which can meet the user's application requirements in terms of performance, quality, and power consumption. The impact crusher is slightly more expensive, but it is widely used.

The above is the difference between the jaw crusher and the impact crusher. When choosing crushing equipment, users should configure them reasonably according to production requirements to obtain higher production capacity and profits. If you want to know more about the mining industry, please consult our customer service online.