Jaw crusher is a type of stone coarse crusher. It is used in the first process of crushing various ores and rocks. It has a large crushing ratio, uniform product particle size, simple structure, reliable operation, easy maintenance, and economical operating costs. With its characteristics, it can be widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy and chemical industries to crush various materials with a compressive strength not exceeding 320 MPa.

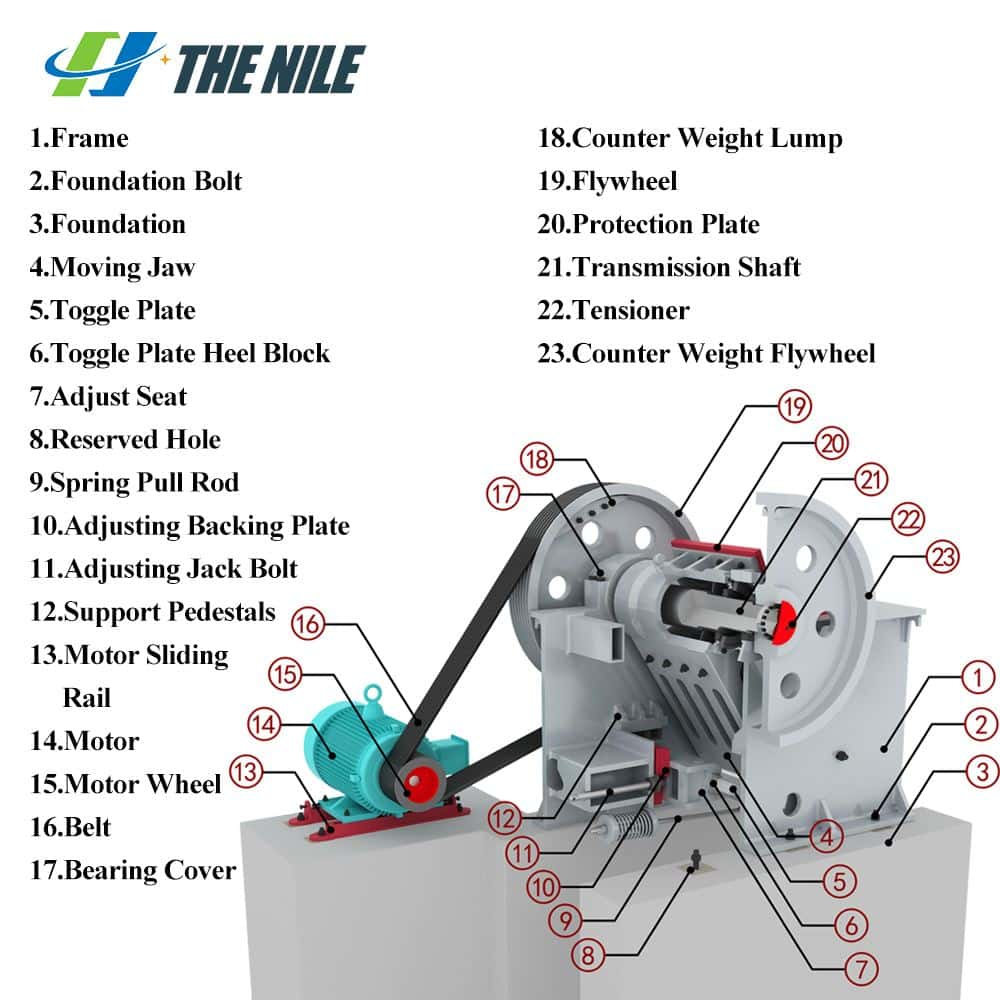

Taking the traditional jaw crusher as an example, as a type of curved extrusion crushing equipment, when the jaw crusher is working, the motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the toggle plate and the movable jaw The angle between the jaws becomes larger, thereby pushing the movable jaw plate closer to the fixed jaw plate. At the same time, the material is crushed or chopped to achieve the purpose of crushing; when the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw plate becomes smaller. The jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. At this time, the crushed material is discharged from the lower opening of the crushing cavity. As the motor continuously rotates, the movable jaw of the crusher makes periodic movements to crush and discharge materials, thus realizing mass production.

The jaw crusher is mainly composed of fixed jaw plate, movable jaw plate, frame, upper and lower guard plates, adjustment seat, movable jaw tie rod, etc.

The advantages of jaw crusher compared with other crushers are:

1. High production efficiency ---"V"-shaped deep cavity crushing has no dead zone, and materials will not be blocked in the crushing cavity, which greatly improves the production efficiency of the equipment.

2. Good stability---By optimizing the overall structure and counterweight part of this model to determine the structure of the flywheel and sheave and the weight of the counterweight, the vibration of this model has been greatly improved. Compared with jaw crushers of the same specification, it has higher stability.

3. High reliability---The heat-treated forged eccentric shaft, oversized bearings, E-type frame, etc. make the equipment sturdy, durable and more reliable.

4. Easy to operate and maintain---The advanced side guard plate bolt fixing system makes it faster to replace the side guard plate of this type of machine; the reasonable machine structure makes it more convenient for this type of machine to adjust the size of the discharge port and replace the toggle plate, greatly shortening the operation and Downtime for maintenance.

5. Wide application---Suitable for various crushing processes.