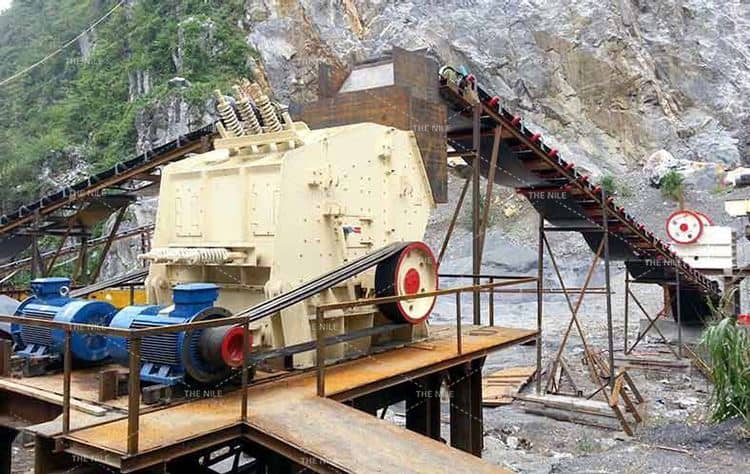

In the field of mining and building materials, as the secondary fine crushing equipment in the crushing process, the impact crusher has a wide range of applications, and the equipment is deeply loved by users. Today, I will summarize the common problems in the use of impact stone crushers and the corresponding solutions to avoid a series of problems caused by machine damage.

1. The bearing temperature continues to rise during the operation of the impact crusher

1. Adding too much or too little lubricating oil will cause the bearing to generate heat.

2. Poor lubricating oil performance or unreasonable selection of lubricating oil varieties and viscosity, so that a good dynamic pressure oil film is not formed between the friction surfaces, and the metal directly touches the friction, resulting in high friction loss and high energy consumption, resulting in a continuous increase in bearing temperature high.

3. The lubricating oil is contaminated, particle impurities cause the lubrication system to block, increase friction, and cause temperature rise. Water mixed into the lubricating oil will cause the viscosity of the lubricating oil to decrease, and boundary friction or even dry friction will occur.

4. Bearing wear. Due to the harsh working environment of the crusher and a lot of dust, part of the fine powder will cause the lubricating oil in the bearing to deteriorate after entering the bearing, resulting in poor lubrication, increased friction, and corresponding wear. The bearing continues to run in a worn state, resulting in high friction, The temperature will increase.

5. The parts are not checked and replaced in time: When the bearing cannot be adjusted under severe fatigue, cracks, oxidation, corrosion, etc., if it is not replaced in time, it will cause bearing heating, vibration, abnormal noise, etc., which will affect production.

Solution: Strictly follow the amount of lubricating oil specified in the instructions of the crusher, add lubricating oil to the bearing part regularly and quantitatively; select lubricating oil of suitable variety and viscosity; regularly check the wear of the bearings and other parts and replace them in time.

2. The impact crushing machine has abnormal vibration during operation

1. The size of the raw material does not match the model of the impact crusher purchased. If the model is too large or too small, the impact crusher will be abnormal.

2. The hammerhead of the impact crusher will cause severe wear of the hammerhead due to long-term crushing of materials with excessive hardness, which will cause vibration.

3. The rotor of the impact stone crusher is unbalanced.

4. The machine is not firmly installed, the fixing screws may be loose, and the pouring platform may collapse.

Solution: When purchasing an impact crusher, choose to purchase according to the size of the material, or listen to the recommendations of professional suppliers; the hammer is the vulnerable part of the impact crusher, and it will be used when the hammer is used for three months. Check the wear of the hammer head and replace it in time; adjust the rotor in a balanced state in time; check the firmness of the machine when installing the machine, and tighten the fixing screws and repair the pouring platform in time.

The above is a detailed introduction and solutions to the common problems of the two impact crushers. In general, we must do a good job in the daily maintenance of the machine and select high-quality suppliers. If you want to know more product knowledge, please consult our customer service online, and we will arrange a professional technician to introduce you in detail.