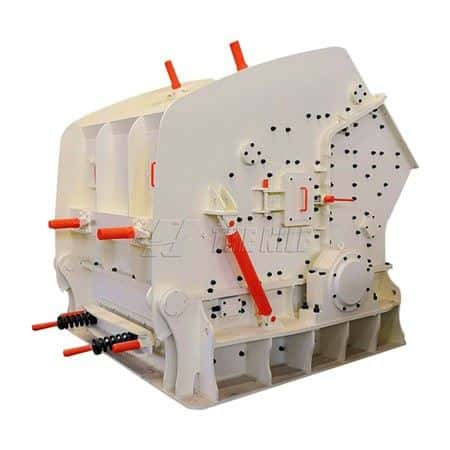

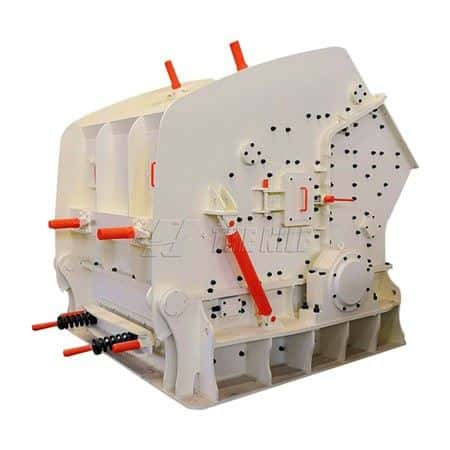

Processing Materials: Tertiary impact crusher, also known as impact crusher, is secondary crushing equipment, which can crush various coarse, medium, and fine materials with feed particle size less than 500mm and compressive strength no more than 350Mpa. It is widely used in various ore crushing, energy, railway, highway, cement, chemical industry, construction, and other industries.

Working Principle of Tertiary Impact Crusher

A tertiary impact crusher is a kind of crushing machine which uses impact energy to crush materials. When the machine is working, the rotor rotates at a high speed driven by the motor. Then the material enters the action area of the plate hammer, it will collide with the plate hammer on the rotor, and then it will be thrown to the impact device for re-crushing, and then it will bounce back from the impact lining plate to the plate hammer action area for re-crushing.

The above process is repeated. The material enters the first, second, and third reaction chambers from large to small for repeated crushing until the material is crushed to the required particle size and discharged from the outlet. Adjusting the gap between the impact frame and the rotor can change the size and shape of the material.

Performance Characteristics of Tertiary Impact Crusher

1.Large impact force, keyless connection: the backplate of the rotor for tertiary impact crusher can bear the high moment of inertia of the rotor and the impact and crushing force of the hammerhead, and counterattack the toothed plate and keyless connection.

2.Energy saving. The tertiary impact crusher machine has been optimized to be a low speed, multi-chamber impact crusher. Its linear speed is reduced by 20% - 25% compared with the general impact crusher, so as to obtain high production capacity with low energy consumption.

3.Good shaping effect. The Tertiary impact crusher has three-stage crushing and shaping functions, so the crushing ratio is large, the product shape is a cube and selective crushing.

4.Long service life and simple maintenance. With the new manufacturing technology, a kind of chromium, molybdenum, and vanadium alloy material with high wear resistance and high toughness has been successfully developed, which solves the problem of crushing hard materials and greatly improves the service life of plate hammer.

5.Hydraulic structure. Tertiary impact crusher is equipped with a multi-functional hydraulic station, with hydraulic high-speed discharge clearance, impact plate stable vibration reduction, and body automatic opening.

Technical Parameters of Tertiary Impact Crusher

Model | Rotor Size | Feed Openning Size | Max. Feeding Size | Output Size | Capacity | Motor Power |

PF-0607 | 644*740 | 320*770 | 100 | 5-60 | 10-20 | 30 |

PF-0807 | 850*700 | 400*730 | 300 | 5-60 | 15-30 | 30-45 |

PF-1008 | 1000*800 | 400*830 | 300 | 5-60 | 30-50 | 37-55 |

PF-1010 | 1000*1050 | 400*1080 | 350 | 5-60 | 50-80 | 55-75 |

PF-1210 | 1250*1050 | 400*1080 | 350 | 5-60 | 70-120 | 110-132 |

PF-1212 | 1250*1250 | 400*1300 | 350 | 5-60 | 100-120 | 132-160 |

PF-1214 | 1250*1400 | 400*1430 | 400 | 5-60 | 130-180 | 160-200 |

PF-1315 | 1320*1500 | 680*1520 | 400 | 5-60 | 160-250 | 180-260 |

PF-1320 | 1320*2000 | 680*2030 | 400 | 5-60 | 300-350 | 300-375 |