Scope of application: Impact stone crusher can crush ores and rocks whose feed size is generally not more than 300mm and compressive strength not more than 150Mpa; it is not suitable for crushing ores or viscous materials with surface moisture greater than 8-10%.

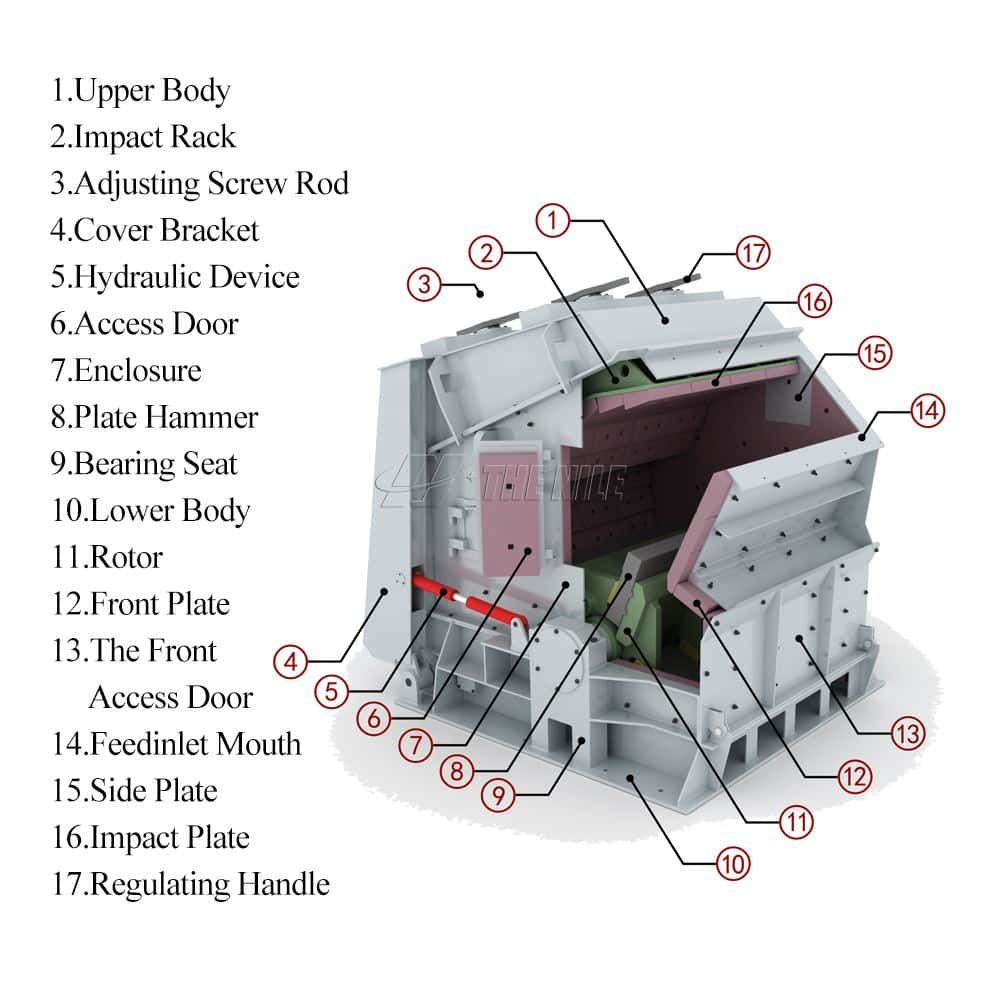

Product introduction:

The impact crushing machine is often used for the secondary crushing of materials. It can handle various medium-hard, soft materials (limestone, coal gangue, concrete, etc.), and is widely used in railways, highways, cement, chemical industries, and other industries. The stone impact crusher has the advantages of good shape, cubic shape, adjustable discharging granularity, and diversified finished product specifications.

Maintenance of impact crusher

1. The impact stone crushing machine runs smoothly. When the vibration of the machine increases suddenly, stop immediately to find out the cause and eliminate it.

2. Under normal conditions, the temperature rise of the bearing should not exceed 35 degrees, and the maximum temperature should not exceed 70 degrees. If it exceeds 70 degrees, stop immediately and find out the cause.

3. When the hammer wear of the impact crusher equipment reaches the limit mark, it should be turned around or replaced in time.

4. After assembling or replacing the blow bar, the rotor balance must be maintained, and the static balance shall not exceed 0.25kg.m.

5. When the frame liner is worn out, it should be replaced in time to avoid abrasion of the casing.

6. Check the tightness of all bolts before starting each time.

Features of impact crusher for sale

1. Large feed inlet, high crushing cavity, high hardness of adaptable materials, and less stone powder.

2. The gap between the impact board and the hammer can be easily adjusted, effectively controlling the size of the output and the shape of the particles is good.

3. The impact rock crusher machine has a compact structure and convenient maintenance.

4. Using high-quality board hammer, impact resistance, abrasion resistance, and high impact force.

5. Complete crushing function, high production efficiency, low mechanical wear, and high comprehensive benefit.

Precautions for impact crusher

1. After stopping the feed, let the stone impact crusher machine continue to run until the remaining materials in the crushing cavity are processed.

2. When the equipment is stopped, first cut off the working power supply.

3. After the impact crusher is stopped, the discharge conveyor can be stopped after the material conveying on the discharge conveyor is completed.

4. After the motor is repaired or re-wired, it is recommended to carefully check the correctness of the direction to ensure that the equipment rotates in the specified direction, and it is strictly forbidden to run in the opposite direction.

5. If the equipment is stopped due to the excessively large size of the crushed material, the user should check the wear of the hammer after stopping to prevent the rotor from being worn out.

6. If the high capacity impact rock crusher is stopped due to severe wear of the blow bars, the user should make the weight of each blow bar equal and maintain balance when adjusting the blow bars 180° and use them again to prevent vibration after starting.

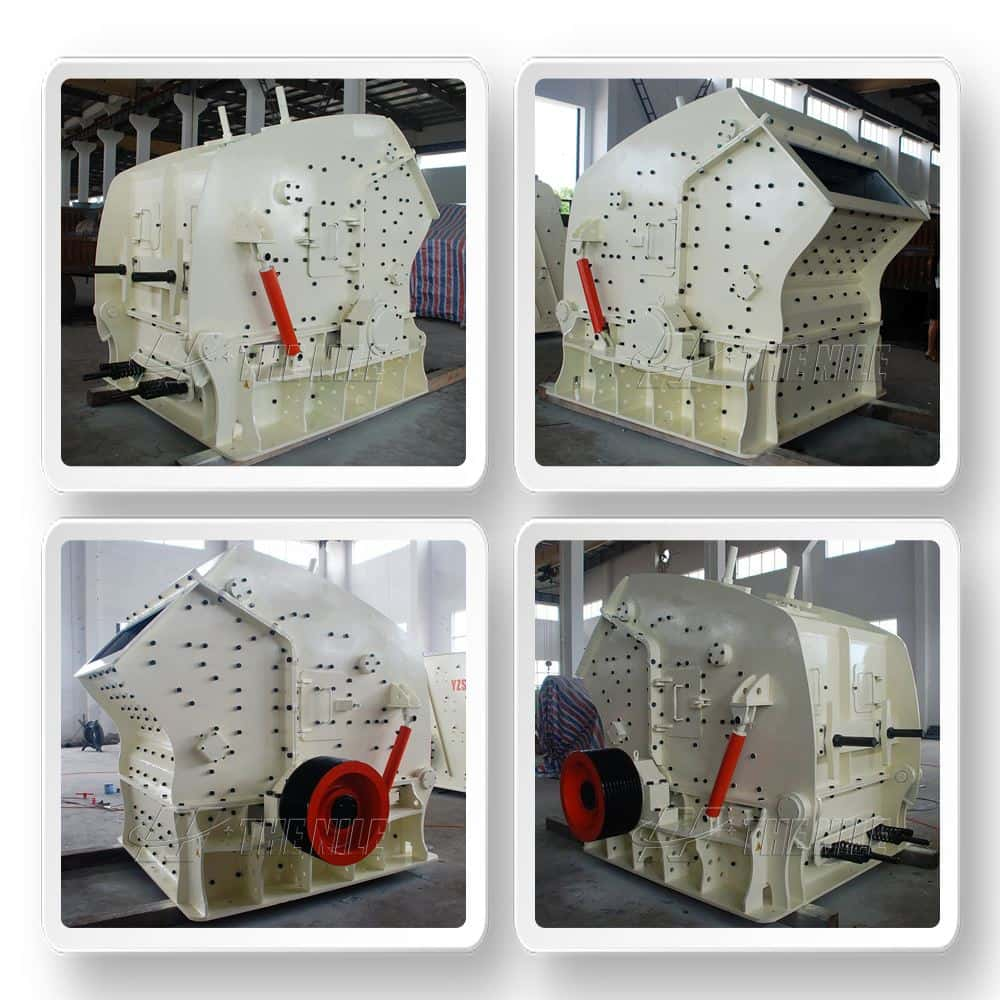

Packing and shipping:

The impact limestone crusher produced by the Nile manufacturer is not only of high quality but also price far lower than the market price. Products can be transported to all parts of the world, and overseas warehouses in Kenya and Sudan can be directly picked up. We use fully enclosed container packaging during the entire transportation process, with a low product damage rate and fast transportation.

| Model | Rotor Size | feed opening | Max. feeding | Output Size | Capacity | Motor Power |

| Size | Size | |||||

| (mm) | (mm) | (mm) | (mm) | (t) | (kW) | |

| PF-1008 | 1000*800 | 400*830 | 300 | 5-60 | 30-50 | 37-55 |

| PF-1010 | 1000*1050 | 400*1080 | 350 | 5-60 | 50-80 | 55-75 |

| PF-1210 | 1250*1050 | 400*1080 | 350 | 5-60 | 70-120 | 110-132 |

| PF-1214 | 1250*1400 | 400*1430 | 400 | 5-60 | 130-180 | 160-200 |

| PF-1315 | 1320*1500 | 680*1520 | 400 | 5-60 | 160-250 | 180-260 |

| PF-1320 | 1320*2000 | 680*2030 | 400 | 5-60 | 300-350 | 300-375 |