Maximum feeding side length: 300-400 Production capacity: 30-350 t/h

Product description:

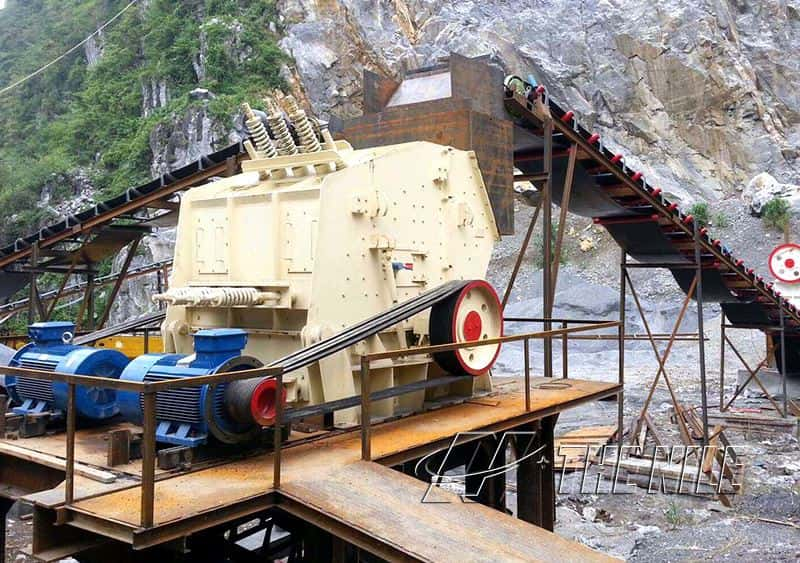

PF impact crusher is often used for the secondary crushing of materials. It is suitable for crushing various soft and hard materials and is widely used in mining, railway, highway, building materials, and other industries. PF impact stone crusher has 6 specifications, users can choose the appropriate model according to the output size, which has the advantages of high work efficiency and large processing capacity.

Working principle:

The stone falls directly into the high-speed rotating turntable from the upper part of the machine; under the action of high-speed centrifugal force, it collides with another part of the flying rocks around the turntable in an umbrella manner to produce high-speed collision and high-density crushing. A vortex motion is formed between the turntable and the casing, causing multiple blows and smashes.

Advantages of impact crusher for sale

1. The impact crushing machine can process materials with high humidity and effectively prevent materials from clogging.

The feed chute and impact plate of the impact crusher can be equipped with a heating device, which is helpful for processing materials with large water content and avoids the sticking of materials.

2. Convenient and flexible, wide adjustment range

The impact rock crusher can adjust the output particle size in many ways, by adjusting the rotor speed, adjusting the gap between the impact plate and the grinder, and other methods.

3. Wide application range, can crush various soft and hard materials

The plate hammer of the impact crusher equipment is fixed on the rotor with a mechanical clamping structure so that the rotor has greater momentum and is suitable for crushing harder materials.

4. Low maintenance cost and convenient replacement of spare parts

The blower of the stone impact crusher is easy to replace. The blower produced by our company is made of special material, which is more wear-resistant and has a long replacement cycle.

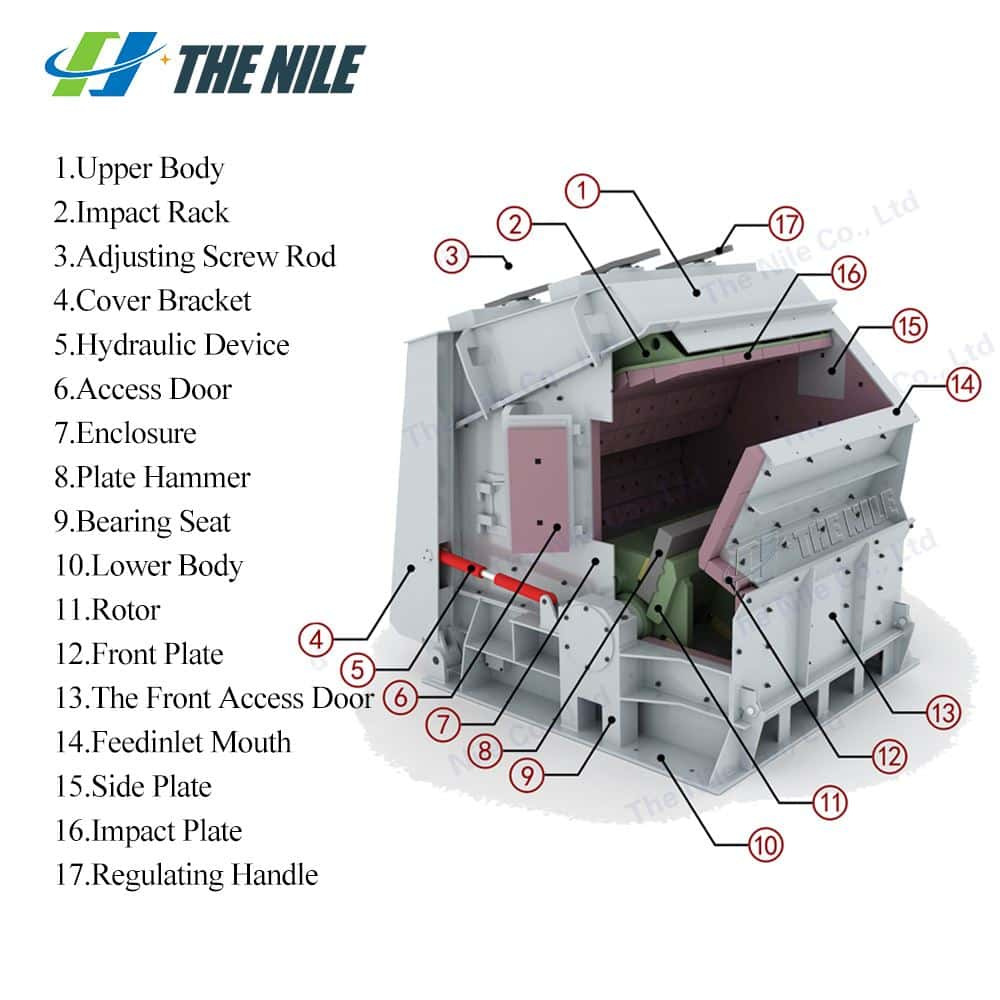

The structure of the impact crusher machinery

The impact stone crusher machine is mainly composed of spring, plate hammer, impact liner, main shaft, rotor, compression block, and so on.

Packaging and shipping

We use double-layer packaging during the entire transportation process, the product is not easy to damage, and can be transported to all parts of the world, the transportation speed is fast.

FAQ:

Q1: Do you provide equipment operation training?

Answer: Yes. We can send professional engineers to the work site for equipment installation, commissioning, and operation training. All our engineers have passports.

Q2: How is the quality of your products?

A: Our products are manufactured in strict accordance with national and international standards, and we will test every device before shipment. We guarantee that if the quality of the product is different from the description we described before you place the order, we promise a 100% refund.

Q3: Is the price of the product reliable?

A: Yes, we are a manufacturer, and we have the strength to provide you with the lowest price compared to other distributors. However, our policy is "according to the order quantity, we will provide the lowest possible price with an absolutely honest business attitude".

Company strength:

The Nile Machinery is an engineering general contracting comprehensive service company with mining machinery production and export as its main business. Since its establishment, it has built a large number of influential international projects and has been widely recognized by the country where it has served 130 Many countries and regions. At present, it operates various types of equipment such as stone crushing equipment, gold beneficiation equipment, sand making equipment, industrial grinding equipment, and mineral ore beneficiation equipment. The business areas cover metallurgy, mining, transportation, building materials, electric power, environmental protection, chemicals, new energy, agricultural products storage, and processing industries.

Project cases:

Case: Limestone crushed stone production line with an hourly output of 600 tons

Material: Limestone

Output: 600 t/h

Configuration equipment: vibrating feeder, jaw crusher, impact crusher, high-efficiency fine crusher, vibrating screen, etc.

Detail display: Recently, a mine owner from Sudan contacted the Nile for a configuration list of the 600t/h limestone crushing production line. After understanding the customer’s needs, our technicians immediately checked the location and weather conditions of the customer’s production site. The specific conditions of the stone materials were investigated and understood in detail, and a reasonable and efficient limestone crushing production line was designed for customers. In the end, we equipped our customers with vibrating feeders, jaw crushers, impact crushers, high-efficiency fine crushers, vibrating screens, etc. Achieved the results expected by customers.

| Model | Rotor Size | feed opening | Max. feeding | Output Size | Capacity | Motor Power |

| Size | Size | |||||

| (mm) | (mm) | (mm) | (mm) | (t) | (kW) | |

| PF-1008 | 1000*800 | 400*830 | 300 | 5-60 | 30-50 | 37-55 |

| PF-1010 | 1000*1050 | 400*1080 | 350 | 5-60 | 50-80 | 55-75 |

| PF-1210 | 1250*1050 | 400*1080 | 350 | 5-60 | 70-120 | 110-132 |

| PF-1214 | 1250*1400 | 400*1430 | 400 | 5-60 | 130-180 | 160-200 |

| PF-1315 | 1320*1500 | 680*1520 | 400 | 5-60 | 160-250 | 180-260 |

| PF-1320 | 1320*2000 | 680*2030 | 400 | 5-60 | 300-350 | 300-375 |