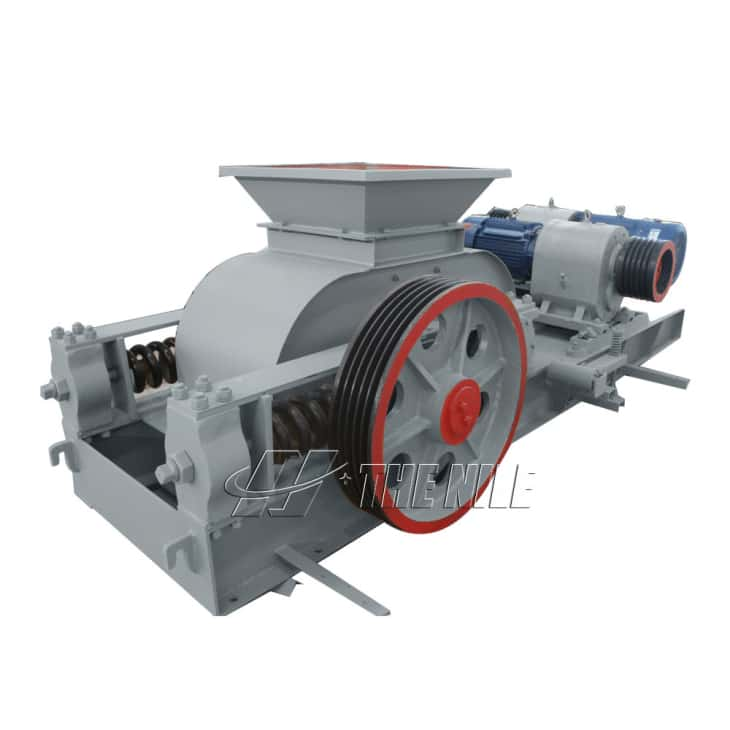

Applied Filed: The surface of 2 roller crusher is made of high manganese steel and can be heat treated. 2 roller crusher is suitable for coarse crushing and intermediate crushing of brittle materials in cement, chemical industry, mining, building materials, metallurgy and other industries.

Product Description of 2-Roller Crusher

2-roll crusher is also called double roll crusher, double tooth roller crusher, etc. It can control the particle size of the output product and effectively crush the material with compressive strength less than 160MPa. The feed size of the 2-roll crusher is less than 25 mm, the discharge size is 1-40 mm, and the production capacity is 5-50 tons per hour.

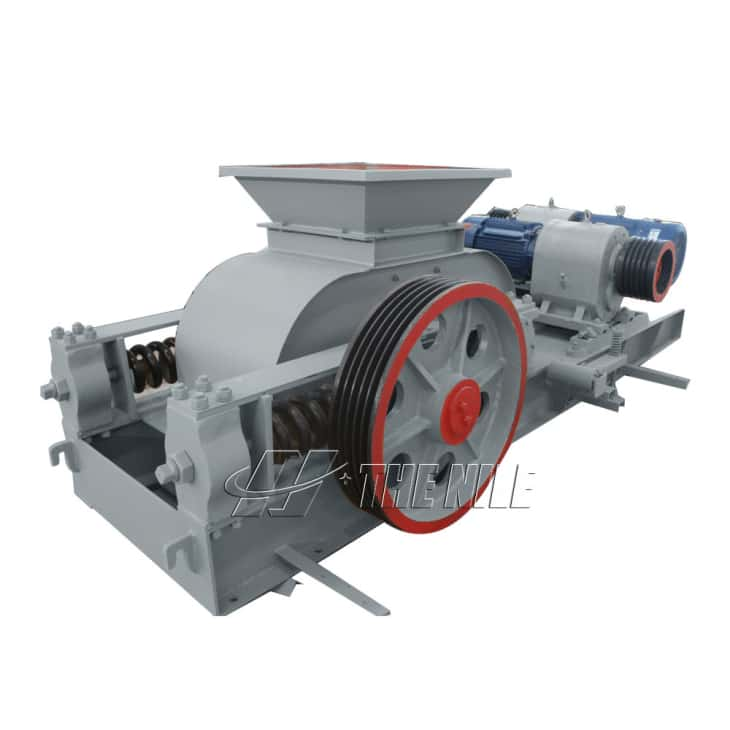

Working Principle of 2-Roll Crusher

The particles are drawn into the gap between the rollers of 2-roll crusher by their rotational motion and the friction angle formed between the rollers and the particles. The particles are forced into a smaller and smaller gap area by the two rollers and then fractures from the compressive forces exerted by the rotating rollers.

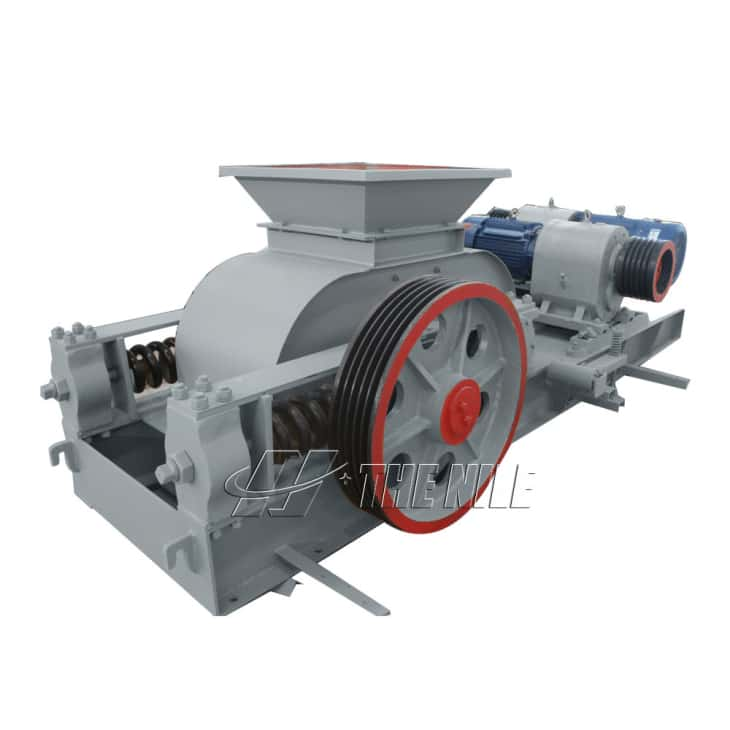

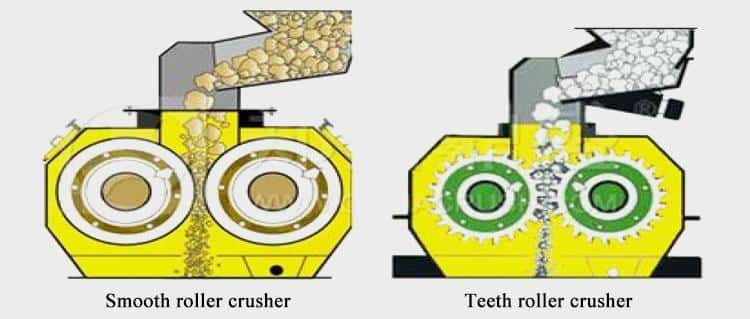

Double Rotor

Two different type roller meet different demands

A3 steel frame

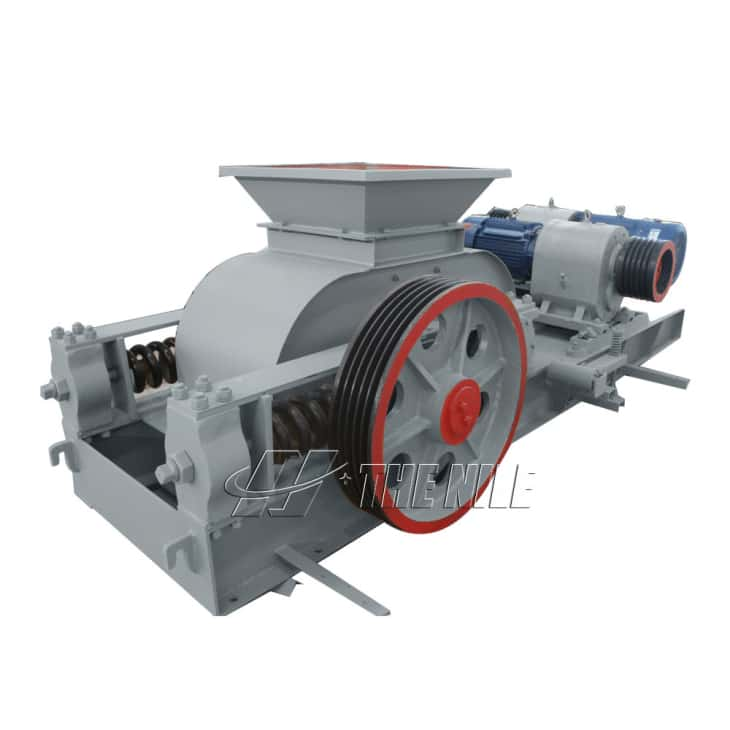

Packing&Shipping

Standard package in wooden boxes or containers

FAQ Q1: Are you factory or trade company? A1: We are factory. Q2: Where your products have been exported before? A2: Our products have been sold to South Asia, Africa, South America, middle East and so on. Q3: How will you help the customer to install the equipment? A3: Our senior engineer will guide the installation and commissioning as well as the initial production at Q4: How about the wear parts supply? A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our technicians to your place and you are therefore, responsible for all thecost involved. Q5: What about the payment method? A5:T/T, L/C Paypal is available Q6: What about after-sale service? A6:12 months warranty for all kinds of products. |

Model | Feeding size | Discharging size | Capacity | Motor power | Weight |

(мм) | (мм) | (t/h) | (kw) | (т) | |

2pgc450×500 | 300 | 15-75 | 20-45 | 7.5×2 | 4.2 |

2pgc600×750 | 400 | 15-125 | 30-80 | 18.5×2 | 7.8 |

2pgc600×900 | 400 | 15-125 | 40-100 | 18.5×2 | 8.4 |

2pgc600×1200 | 400 | 15-125 | 50-120 | 22×2 | 11.2 |

2pgc800×1000 | 400 | 20-150 | 80-180 | 22×2 | 12.6 |

2pgc800×1200 | 400 | 20-150 | 100-220 | 30×2 | 15.2 |

2pgc900×900 | 500 | 30-150 | 80-180 | 30×2 | 14.5 |