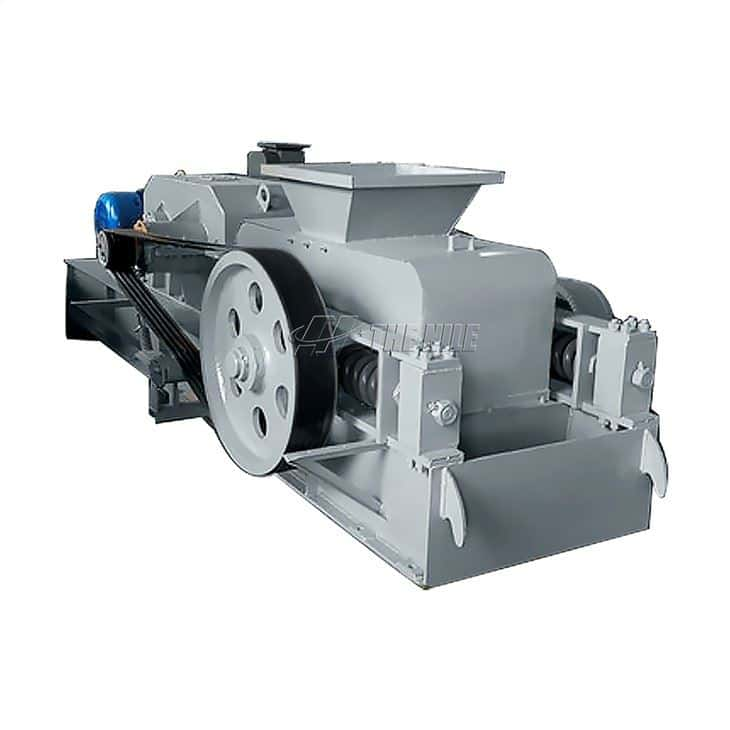

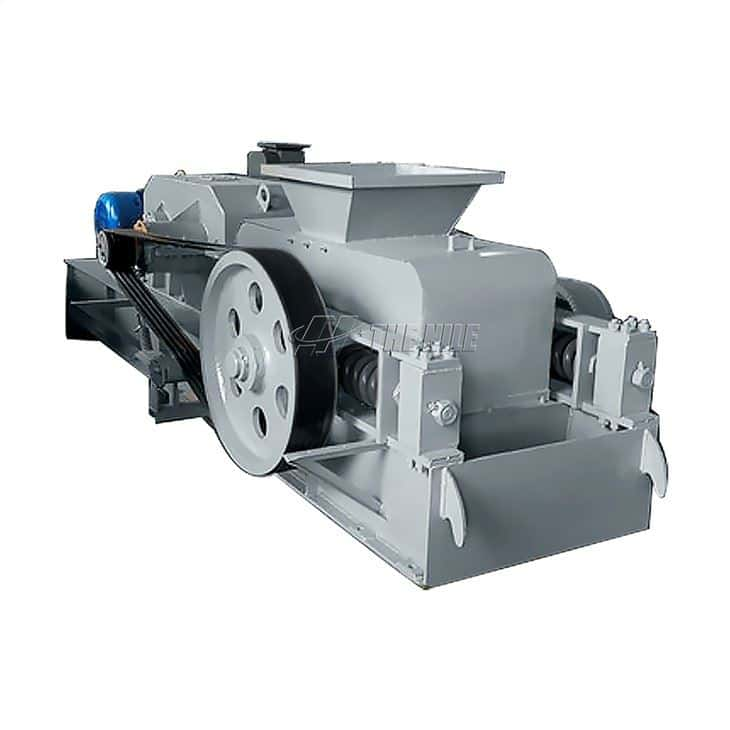

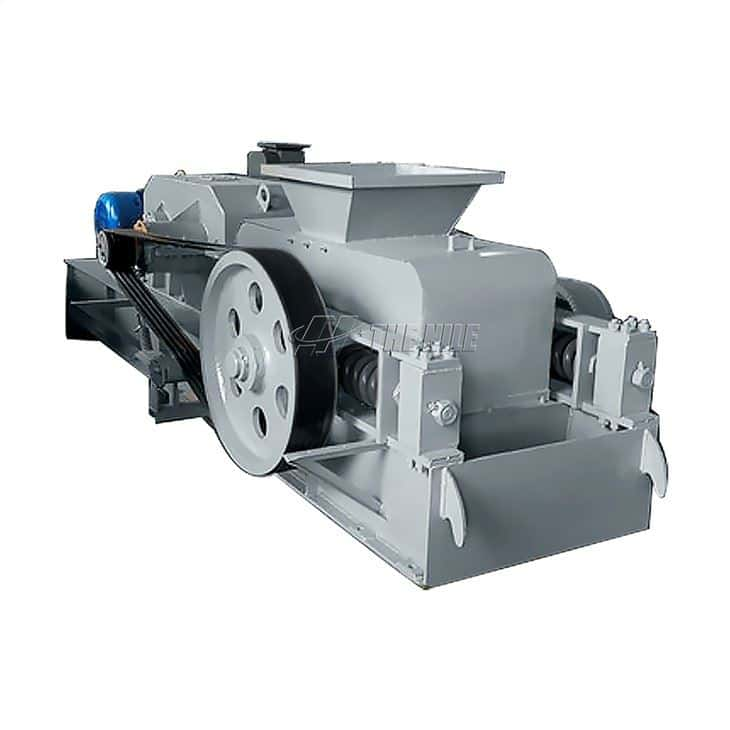

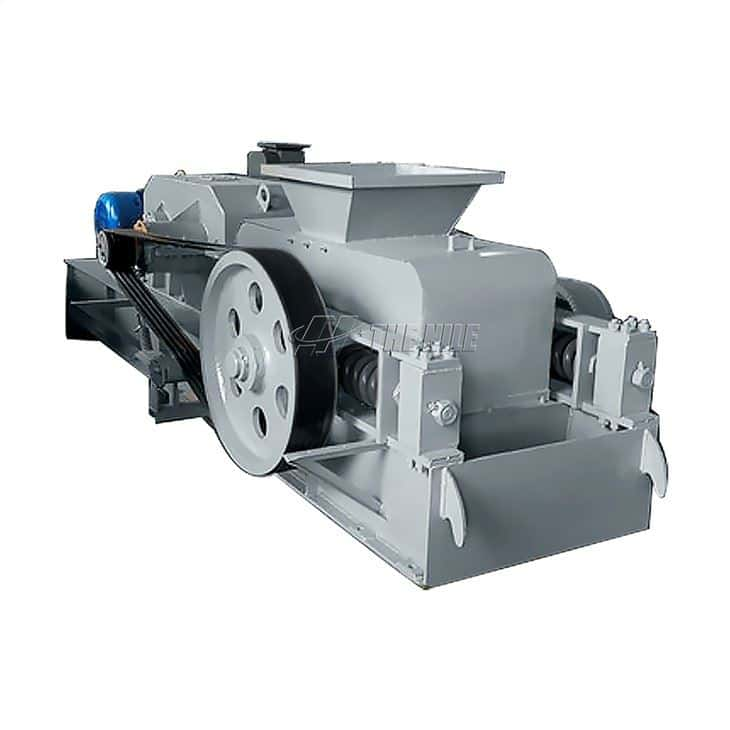

The roller stone crusher machine has a simple structure. The tooth profile, size, and arrangement of the roller surface can be changed with the nature of the material. It can crush medium-hard and soft ores in the middle and fine.

Product description:

The double roller crusher is also called the roller crusher, which is the traditional crushing equipment. The roller crusher machine can crush materials with a compressive strength of ≤160MPa and is widely used in cement, chemical, electric power, building materials, refractory materials, mining, and other industries for coarse and medium-machine crushing of brittle lump materials.

Working principle:

The material to be crushed is fed into the feeding port of the roller stone crusher machine from the feeder, and the material falls between the two rollers through the feeding port, squeezed and crushed, and the finished material is discharged from the discharge port. A wedge or shim adjusting device is installed between the two rollers. The top of the wedge device is equipped with an adjusting bolt. When the adjusting bolt pulls the wedge up, the wedge pushes the movable roller away from the fixed wheel, that is, the gap between the two rollers. When the wedge is down, the gap between the two wheels of the movable roller becomes smaller under the action of the compression spring, and the discharging particle size becomes smaller.

Features of roller crusher equipment

1. The two rollers are equipped with a wedge-shaped adjusting device, which can adjust the discharge particle size according to user requirements.

2. Good crushing effect and high working efficiency.

3. Simple structure and convenient maintenance.

4. Long service life and low maintenance cost.

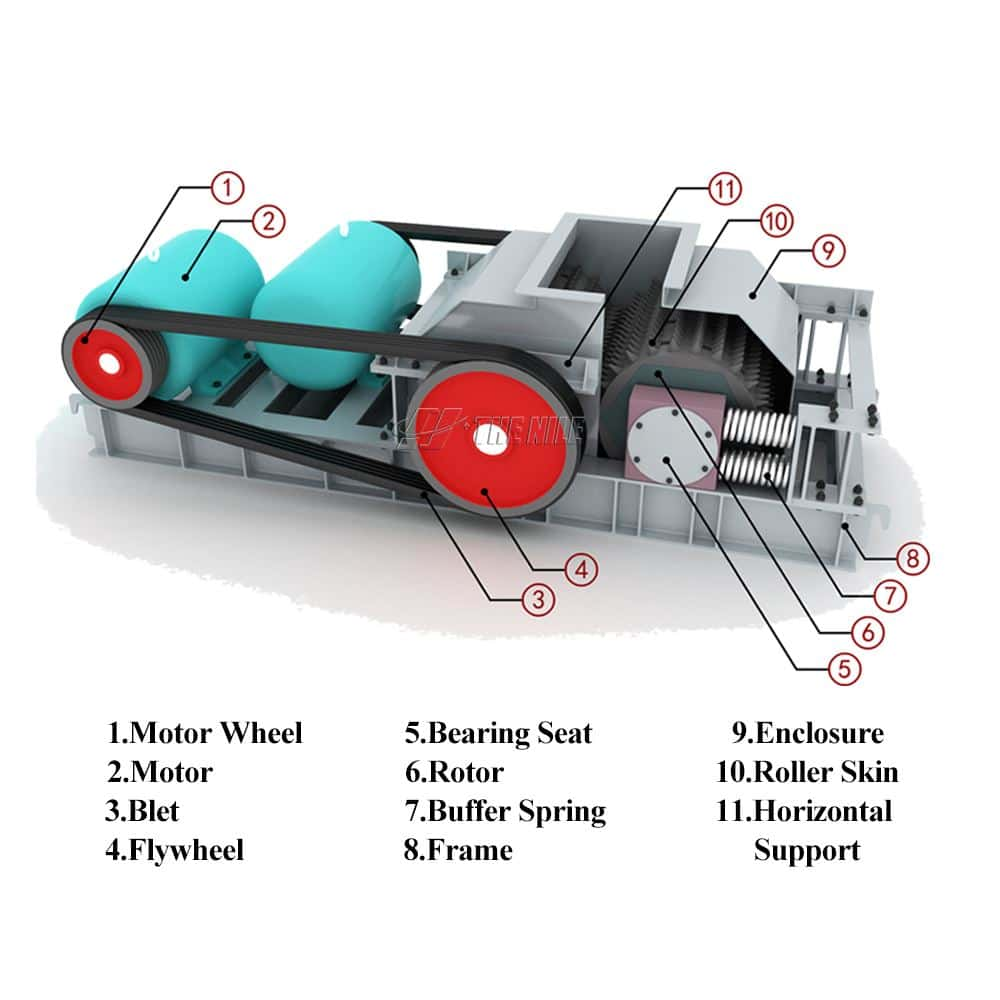

The structure of the roller stone crusher machine

The roller crusher machine is mainly composed of rollers, roller support bearings, pressing and adjusting devices, and driving devices.

Factory shots

Company strength:

The Nile Machinery Co., Ltd. is committed to designing a variety of equipment such as stone crushing equipment, gold beneficiation equipment, mineral ore beneficiation equipment, and sand making equipment, which are widely used in electric power, metallurgy, mining, quarry, and other industries. The products are exported to all parts of the world, especially in Europe, America, Asia, and Africa, and are well received by customers. At present, we have our own overseas warehouses in Kenya and Sudan, and users can observe the machines up close and buy them.

Pre-sale service:

(1) Professional technicians provide customers with suggestions for model selection.

(2) Design and manufacture machines according to customers' special requirements.

After-sales service:

(1)) Arrange technicians to guide the installation

(2) If your machine is out of warranty, you can buy spare parts from us at the best price.

(3) Engineers can repair machines overseas

Packaging and transportation

| model | Feeding size | Discharging size | Capacity | Motor power | Weight |

| (мм) | (мм) | (t/h) | (kW) | (т) | |

| 2pgc450×500 | ≤300 | 15-75 | 20-45 | 7.5×2 | 4.2 |

| 2pgc600×750 | ≤400 | 15-125 | 30-80 | 18.5×2 | 7.8 |

| 2pgc600×900 | ≤400 | 15-125 | 40-100 | 18.5×2 | 8.4 |

| 2pgc600×1200 | ≤400 | 15-125 | 50-120 | 22×2 | 11.2 |

| 2pgc800×1000 | ≤400 | 20-150 | 80-180 | 22×2 | 12.6 |

| 2pgc800×1200 | ≤400 | 20-150 | 100-220 | 30×2 | 15.2 |

| 2pgc900×900 | ≤500 | 30-150 | 80-180 | 30×2 | 14.5 |