Applicable materials: crushing sand production of river pebble, calcite, quartz, glass, marble, cobblestone, iron ore, bluestone, mountain stone, water slag, limestone, diabase, granite, basalt, and other materials.

Product description

The roller crusher machine is the traditional crushing equipment. After many upgrades, the roller crusher has finer crushing granularity, larger processing capacity and simple operation, wide application range, long service life, and adjustable discharge particle size. Unanimously, it has been recognized and favored by customers.

The working principle of the dual roll crusher

A wedge or gasket adjustment device is installed between the two rollers of the roller crusher. The top of the wedge device is equipped with an adjustment bolt. When the adjustment bolt pulls the wedge up, the wedge pushes the movable roller away from the fixed wheel. , That is, the gap between the two rollers becomes larger, and the discharging granularity becomes larger. When the wedge is downward, the gap between the two wheels of the movable roller becomes smaller under the action of the compression spring, and the discharging granularity becomes smaller. The shim device adjusts the discharge particle size by increasing or decreasing the number or thickness of the shim. When the shim is increased, the gap between the two rollers becomes larger, and when the shim is reduced, the gap between the two rollers becomes smaller and the output particle size becomes smaller.

Features of double roller crusher machine

1. Low noise and reliable performance

The roller crushing technology has strong production strength, stable and reliable performance, can reduce noise pollution, and has an environmentally friendly effect.

2. High production efficiency and large processing capacity

The crushed product is cube-shaped, with low needle-flake content, no internal cracks, and fine discharging particle size, which improves product quality and efficiency

3. Long service life and low loss of wearing parts

The wear cycle of the roller skin is long, and the wearing parts adopt the current domestic new high-strength wear-resistant materials, which can crush high-hardness materials, have little loss, and have a long service life, which can bring considerable economic benefits to customers

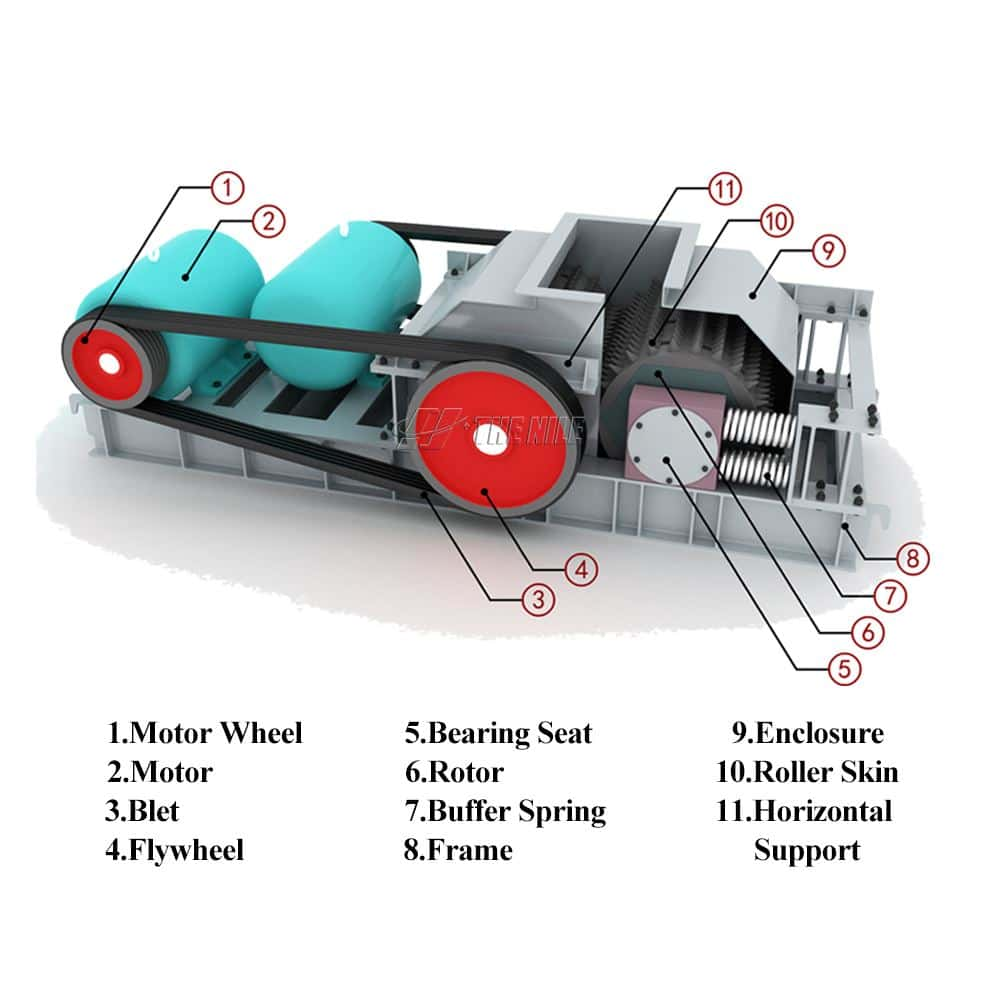

The structure of the twin roller crusher

The roller crusher machine is mainly composed of rollers, pressing and adjusting devices, roller support bearings, and driving devices.

Packaging and shipping

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

| model | Feeding size | Discharging size | Capacity | Motor power | Weight |

| (мм) | (мм) | (t/h) | (kW) | (т) | |

| 2pgc450×500 | ≤300 | 15-75 | 20-45 | 7.5×2 | 4.2 |

| 2pgc600×750 | ≤400 | 15-125 | 30-80 | 18.5×2 | 7.8 |

| 2pgc600×900 | ≤400 | 15-125 | 40-100 | 18.5×2 | 8.4 |

| 2pgc600×1200 | ≤400 | 15-125 | 50-120 | 22×2 | 11.2 |

| 2pgc800×1000 | ≤400 | 20-150 | 80-180 | 22×2 | 12.6 |

| 2pgc800×1200 | ≤400 | 20-150 | 100-220 | 30×2 | 15.2 |

| 2pgc900×900 | ≤500 | 30-150 | 80-180 | 30×2 | 14.5 |