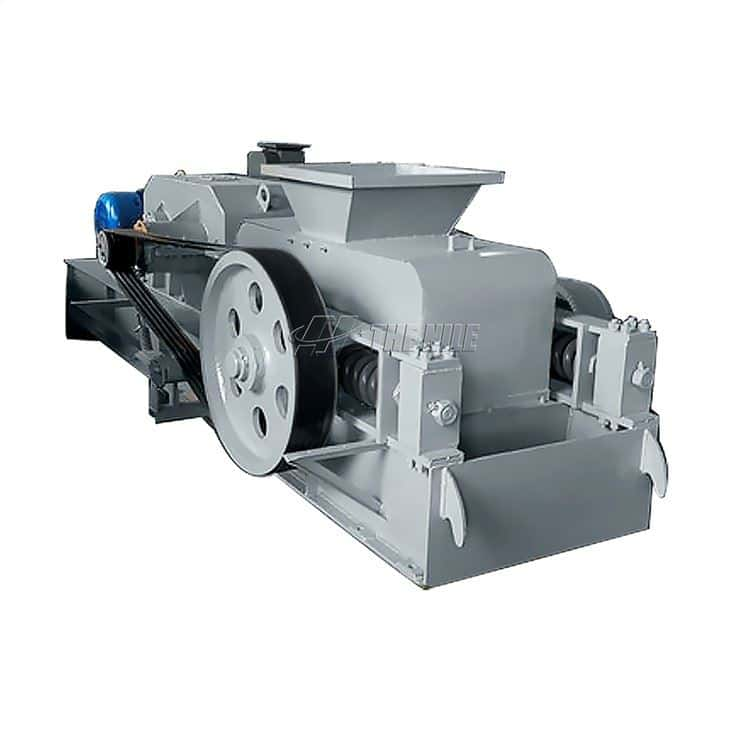

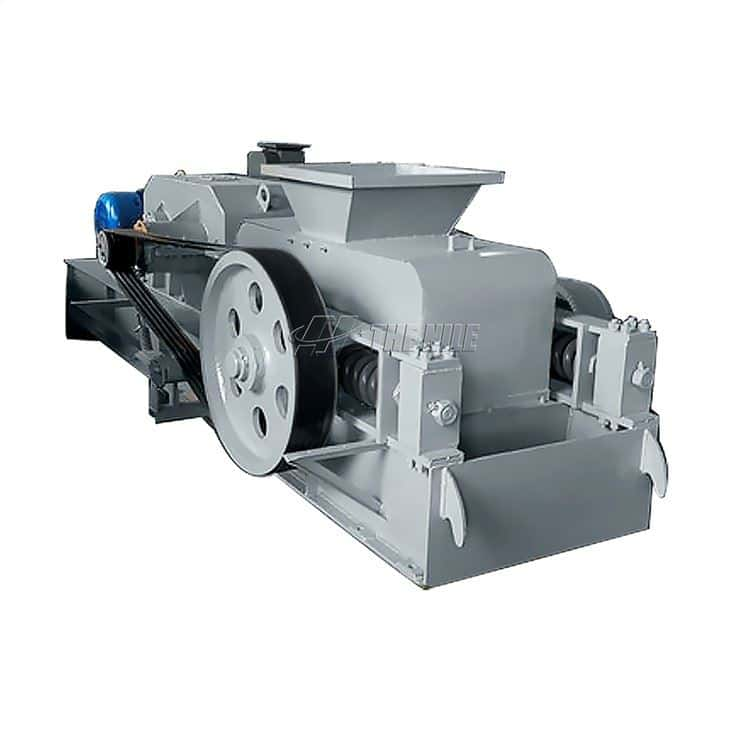

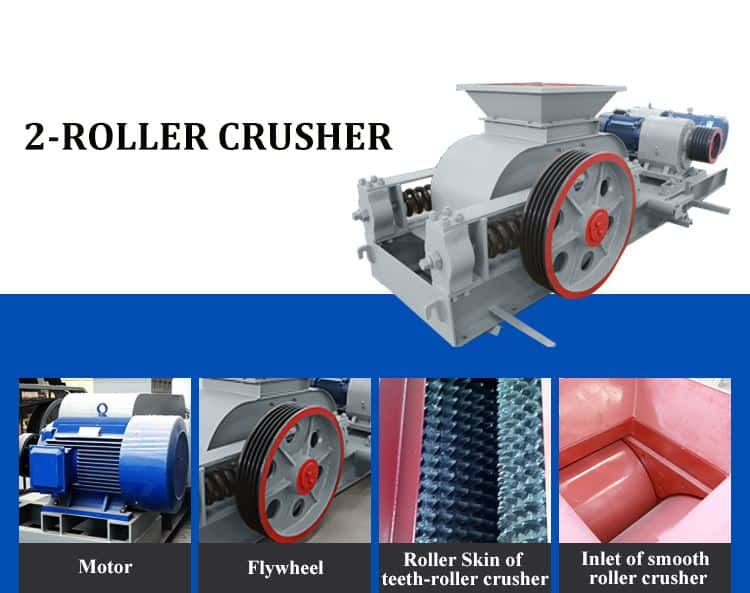

The double roller crusher machine has a simple structure. The tooth profile, size, and arrangement of the roller surface can be changed with the nature of the material. It can crush medium-hard and soft ores in the middle and fine. The 2-roller crushing machine is widely used in various minerals, such as limestone, feldspar, coal, and so on.

Product Introduction

The double roller crusher is abbreviated as the roller crusher, which is the traditional crushing equipment. The structure of the roller crusher is simple, and the phenomenon of excessive crushing is less. The tooth profile, size, and arrangement on the roller surface can be changed with the nature of the material. It can crush medium-hard and soft ore. For example, in sulfuric acid plants, a jaw crusher is usually used to coarsely crush pyrite ore to a diameter of 20~30mm, and then a double-roll crusher is used for the secondary crushing to make the ore The diameter is less than 5mm, which meets the requirements of the boiling furnace.

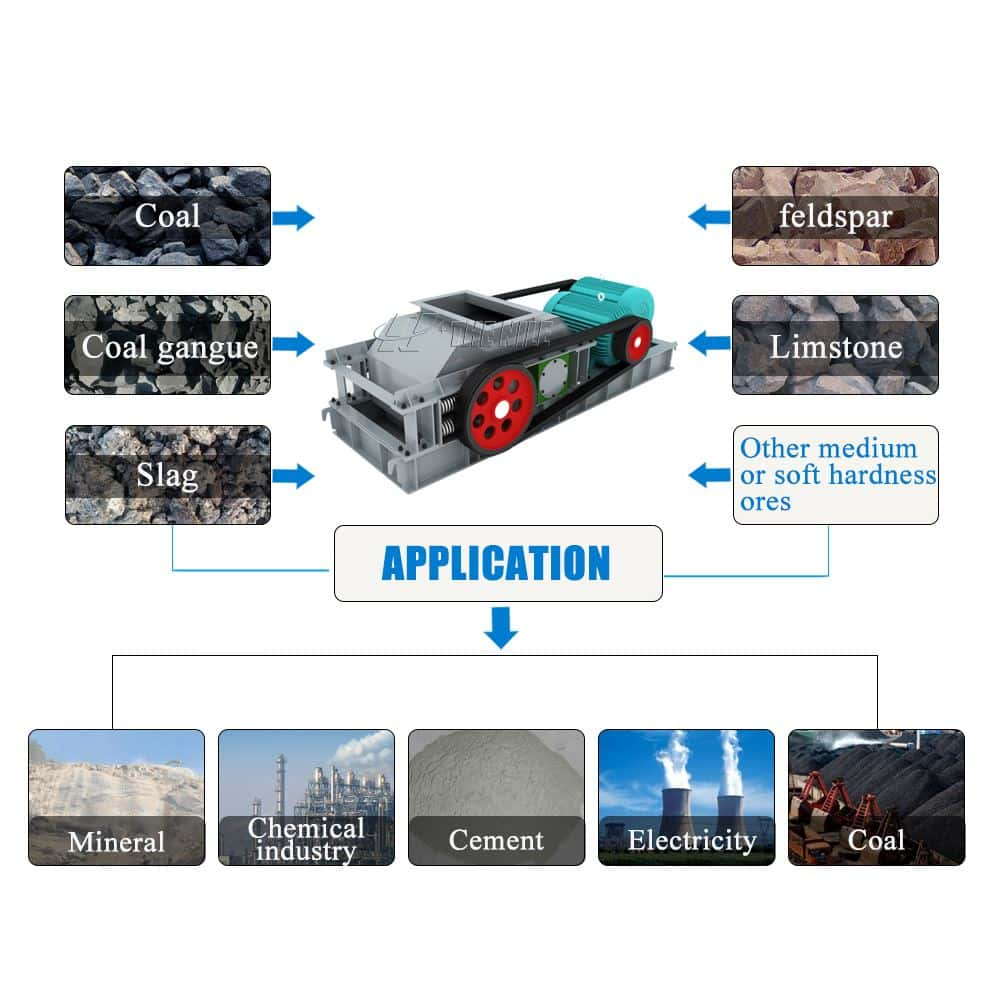

Application of 2-roller crusher equipment

The roller stone crusher machinecan be used for finely crushing various high and medium hardness ores and rocks in the industrial sectors such as mineral processing, chemical industry, cement, refractory materials, abrasives, building materials, etc. Especially in the building materials industry, it has a better crushing effect than general crushing machinery. At present, it has been widely used.

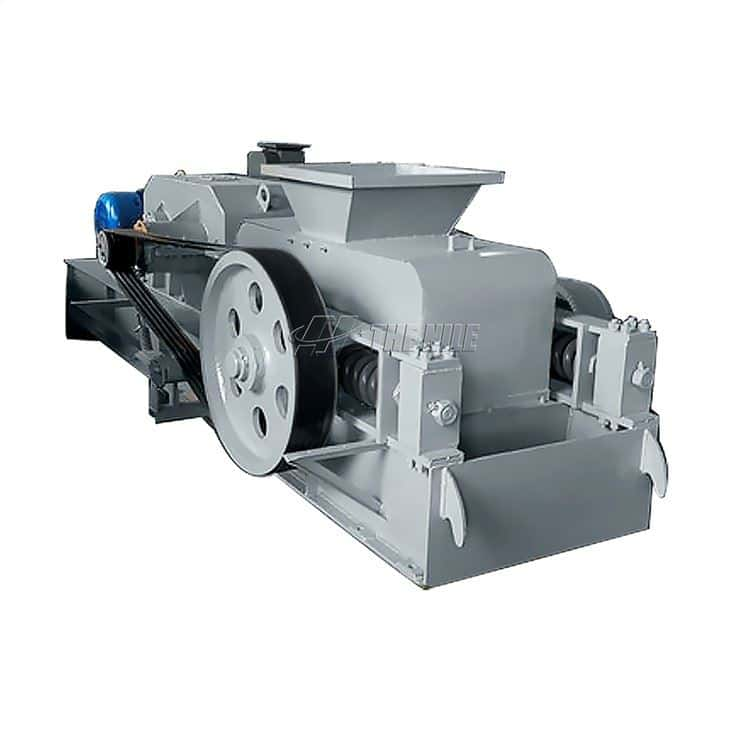

The working principle of the roller crusher forsale

A wedge or shim adjusting device is installed between the two rollers. The top of the wedge device is equipped with an adjusting bolt. When the adjusting bolt pulls the wedge up, the wedge pushes the movable roller away from the fixed wheel, that is, the gap between the two rollers. When the wedge is down, the gap between the two wheels of the movable roller becomes smaller under the action of the compression spring, and the discharging particle size becomes smaller. The gasket device adjusts the discharging particle size by increasing or decreasing the number or thickness of the gasket. When the gasket is increased, the gap between the two rollers becomes larger, and when the gasket is reduced, the gap between the two rollers becomes smaller and the discharge particle size becomes smaller.

Our service:

Pre-sale service:

(1) Professional technicians provide customers with suggestions for model selection.

(2) Design and manufacture machines according to customers' special requirements.

After-sales service:

(1)) Arrange technicians to guide the installation

(2) If your machine is out of warranty, you can buy spare parts from us at the best price.

(3) Engineers can repair machines overseas

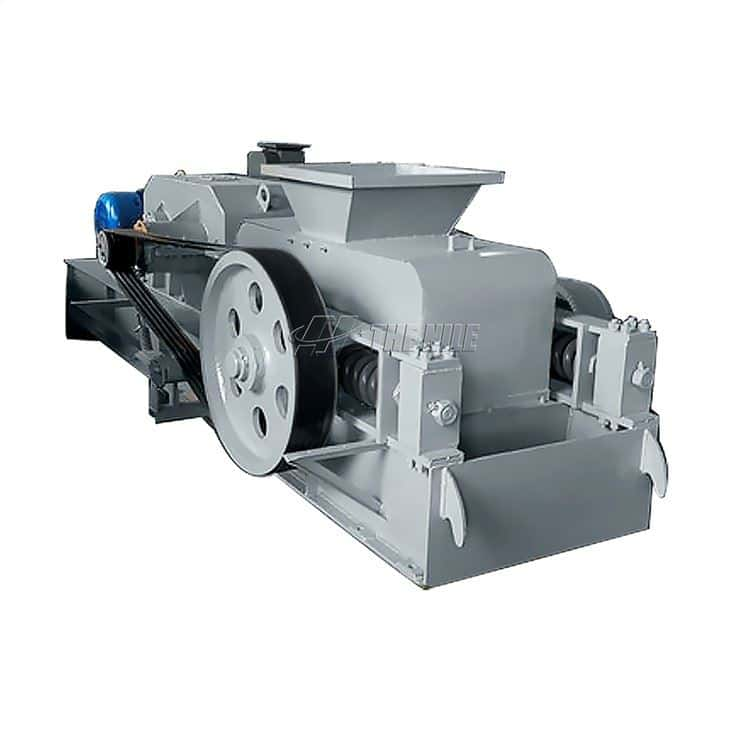

| model | Feeding size | Discharging size | Capacity | Motor power | Weight |

| (мм) | (мм) | (t/h) | (kW) | (т) | |

| 2pgc450×500 | ≤300 | 15-75 | 20-45 | 7.5×2 | 4.2 |

| 2pgc600×750 | ≤400 | 15-125 | 30-80 | 18.5×2 | 7.8 |

| 2pgc600×900 | ≤400 | 15-125 | 40-100 | 18.5×2 | 8.4 |

| 2pgc600×1200 | ≤400 | 15-125 | 50-120 | 22×2 | 11.2 |

| 2pgc800×1000 | ≤400 | 20-150 | 80-180 | 22×2 | 12.6 |

| 2pgc800×1200 | ≤400 | 20-150 | 100-220 | 30×2 | 15.2 |

| 2pgc900×900 | ≤500 | 30-150 | 80-180 | 30×2 | 14.5 |