Processing Materials: Dual roller crusher adopts the extrusion crushing principle with a large crushing ratio, which can be used to do coarse, medium and fine crushing for high hardness materials, such as coal, limestone and slag etc. The whole crushing equipment runs smoothly and has strong production capacity.

Technical Parameters

Model | Feeding size | Discharging size | Capacity | Motor power | Weight |

(мм) | (мм) | (t/h) | (kw) | (т) | |

2pgc450×500 | 300 | 15-75 | 20-45 | 7.5×2 | 4.2 |

2pgc600×750 | 400 | 15-125 | 30-80 | 18.5×2 | 7.8 |

2pgc600×900 | 400 | 15-125 | 40-100 | 18.5×2 | 8.4 |

2pgc600×1200 | 400 | 15-125 | 50-120 | 22×2 | 11.2 |

2pgc800×1000 | 400 | 20-150 | 80-180 | 22×2 | 12.6 |

2pgc800×1200 | 400 | 20-150 | 100-220 | 30×2 | 15.2 |

2pgc900×900 | 500 | 30-150 | 80-180 | 30×2 | 14.5 |

Introduction of Dual Roller Crusher

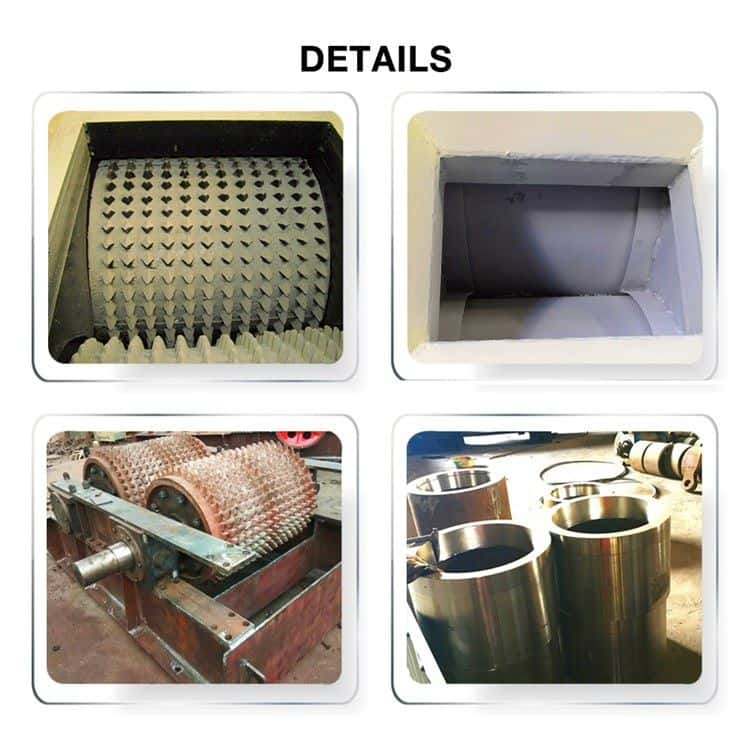

A dual roller crusher that uses two opposite rotating rollers to crush materials. It is composed of a motor, bracket, fixed roller, movable roller, and safety spring. The roll surface is mostly smooth. The bearing of the movable roller can move along the frame and be supported by a strong safety spring. When a particularly hard object falls in, the bearing can move away and spit out the object. Before the normal operation, the gap between the two rolls should be adjusted with the gasket to ensure the crushing ratio.

Advantages ofDual Roller Crusher

1.Roller crusher adopts the method of "more crushing and less grinding", which makes the finished product has a good grain shape. The roller crusher can achieve the effect of more crushing and less grinding, and improve production efficiency by reducing the grinder size and improve the crushing characteristics of the ground materials. The crushed products are mostly cubes with less needle-like content, no tension, and cracks, and the finished products are fine and of high quality.

2.Nile Machinery roller crusher has a long service life and low operation cost. The toothed rollers of roll crusher are made of high-yield wear-resistant materials, which have the characteristics of strong impact resistance and high wear resistance. The crushing equipment has a small loss and low failure rate when crushing materials, which reduce the subsequent maintenance and maintenance costs, save operating costs, and prolong the service life.

3.Less dust overflow and friendly environmental protection. The roll crusher introduces an advanced mining machine concept, equipped with an advanced environmental protection device and closed production, which has low noise, low dust, and low pollution in the whole production process.

Technical Parameters of Dual Roller Crusher

Model | Feeding size | Discharging size | Capacity | Motor power | Weight |

(мм) | (мм) | (t/h) | (kw) | (т) | |

2pgc450×500 | 300 | 15-75 | 20-45 | 7.5×2 | 4.2 |

2pgc600×750 | 400 | 15-125 | 30-80 | 18.5×2 | 7.8 |

2pgc600×900 | 400 | 15-125 | 40-100 | 18.5×2 | 8.4 |

2pgc600×1200 | 400 | 15-125 | 50-120 | 22×2 | 11.2 |

2pgc800×1000 | 400 | 20-150 | 80-180 | 22×2 | 12.6 |

2pgc800×1200 | 400 | 20-150 | 100-220 | 30×2 | 15.2 |

2pgc900×900 | 500 | 30-150 | 80-180 | 30×2 | 14.5 |