Processing Materials: Straw crusher can crush corn stalk, straw, peanut skin, beanstalk, firewood, and other combustible crop waste stalks, so as to avoid the burning of these crop stalks, protect the environment, and effectively develop renewable energy. This machine has the advantages of reliable performance, simple and convenient operation.

Technical Parameters

| Voltage | 220v/380v (Optional) |

| Power | 3-4.8kw |

| Speed | 2800r/min |

| Capacity(680Model) | 600-900kg/h (Cutting Grass) |

| 400-600kg/h (Crushing) | |

| Capacity(580Model) | 450-750kg/h (Cutting Grass) |

| 300-500kg/h (Crushing) | |

| Size(680Model) | 135*110*150cm |

| Size(580Model) | 115*92*150cm |

| Weight(680Model) | 90kg(Don't include the weight of motor) |

| Weight(680Model) | 78kg(Don't include the weight of motor) |

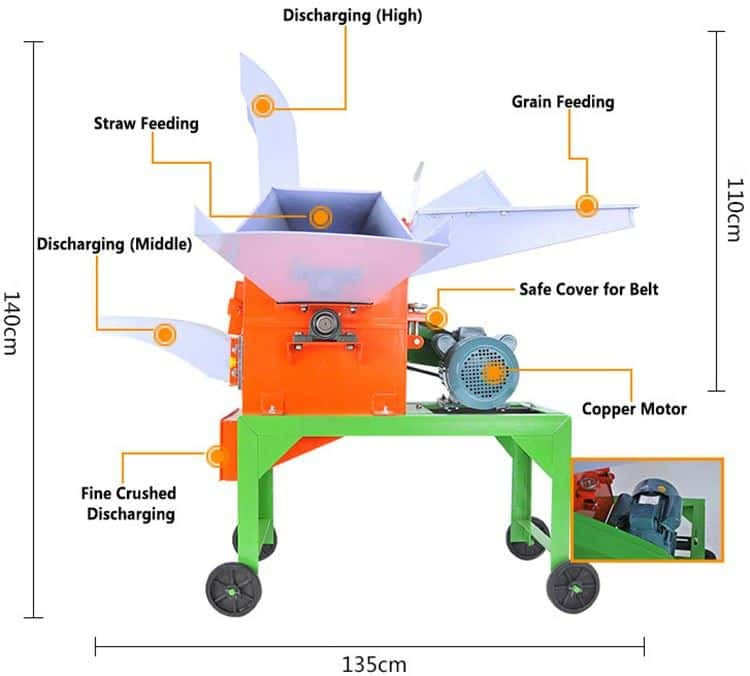

Introduction of Straw Crusher

Straw crusher is mainly used for the chopping of crop straw, branches, and other straw with a diameter of less than 5cm, and also for the chopping of various crop straws and pastures.The whole set of equipment of this machine is mainly used for shredding and processing of biomass such as cotton stalks, bark, branches, corn stalks, wheat stalks, straws, etc. The processed products can be used for power generation, papermaking, wood-based panels, and extraction of hexanol, etc. The crushing length can be manufactured according to customer requirements. The crushed agricultural and plant debris can be used to make organic fertilizer, fuel, particleboard, paper, and other raw materials for various production industries. The equipment turns a large amount of green garbage that was difficult to sell into waste and exerts new economic value. At the same time, it also protects the environment, improves the soil, and creates good social benefits.

Features of Straw Crusher

1.The straw crusher has the advantages of reasonable design, reliable manufacturing quality, simple structure, convenient operation, small volume, less land occupation, labor-saving, and electricity saving.

2.The design of a fully automatic control electric heating device can randomly adjust the dry humidity of materials to ensure the stability of discharge molding and improve work efficiency.

3.The main parts of this crusher machine are made of wear-resistant materials which being special treatment, so they can be continuously pressed and durable for production.

The Safe Operation Tips of Straw Crusher

1.The straw crusher should be fixed on the ground and can be fixed with cement. If the working place changes frequently, the grinder and motor should be installed on the frame made of angle steel.

2.After installing the straw crusher, carefully check whether it is installed in place and whether it is not installed firmly enough. Whether the motor shaft is parallel to the crusher shaft, and at the same time check whether the tightness of the drive belt is appropriate.

3.Before starting the straw grinder, turn the rotor by hand to check whether the operation is flexible and normal, whether there is any collision in the casing, whether the rotation direction of the rotor is correct and whether the lubrication of the motor and the grinder is good.

4.Don't change the pulley of the straw crusher frequently, in case the rotation speed is too high or too low.

5.The straw grinder should be idle for 2 to 3 minutes after start-up, and then feeding work can be done after no abnormal phenomenon.

6.The feeding of straw crusher should be even. In case of noise, high temperature of bearing and body, or material spraying, the machine should be stopped immediately for inspection and troubleshooting.

7.The staff should carefully check the materials before the straw crusher works to prevent hard objects such as metals and stones from entering the crushing chamber to cause accidents.

8.When feeding, the staff should stand on the side of the straw crusher to prevent being hurt by the rebounding debris.

The straw crusher should stop feeding before the shutdown, and cut off the power supply after the materials are removed in standby. Cleaning and maintenance should be carried out after the shutdown.

Maintenance of Straw Crusher

1.Regularly check the power supply, and check the power socket, plug and power cord for oxygen loss or breakage.

2.Regularly check whether the lubrication condition of the bearing is in good condition, and regularly use lubricating oil for maintenance.

3.Regularly check whether all fasteners are tight, and deal with them in time if they are loose.

4.Regularly check whether the drive belt is installed correctly and in good condition. If the belt is found to be damaged, it should be replaced in time. When there are oil stains on the belt or sheave, it should be wiped with a clean rag in time.

5.Regularly check whether the protective device is in good condition. If the protective device is found to be unsafe, it should be eliminated in time.

6.Regularly check whether there are materials or other debris in the damaged cavity, and remove them if necessary.

7.Regularly check whether the head of the hydraulic jacking machine or the jacking screw is retracted and whether the adjusting gasket is installed correctly and pressed tightly.

8.Regularly check the sealing condition of the fan to prevent the sand and soil from causing serious abrasion on the wind machine, causing the impeller body and the rivet head of the hub to fall off, and fatigue cracks at the rivet hole.

Technical Parameters of Straw Crusher

| Voltage | 220v/380v (Optional) |

| Power | 3-4.8kw |

| Speed | 2800r/min |

| Capacity(680Model) | 600-900kg/h (Cutting Grass) |

| 400-600kg/h (Crushing) | |

| Capacity(580Model) | 450-750kg/h (Cutting Grass) |

| 300-500kg/h (Crushing) | |

| Size(680Model) | 135*110*150cm |

| Size(580Model) | 115*92*150cm |

| Weight(680Model) | 90kg(Don't include the weight of motor) |

| Weight(680Model) | 78kg(Don't include the weight of motor) |