Processing Materials: Granite jaw crushers are widely used in metal and non-metal mines, cement plants, construction, sand metallurgy and other industries, non-ferrous metal ore, granite, limestone, quartzite, sandstone, cobblestone, etc. Applied Filed: Granite jaw crusher is widely used in metallurgy, construction, hydropower, transportation, chemical industry, building materials industry.

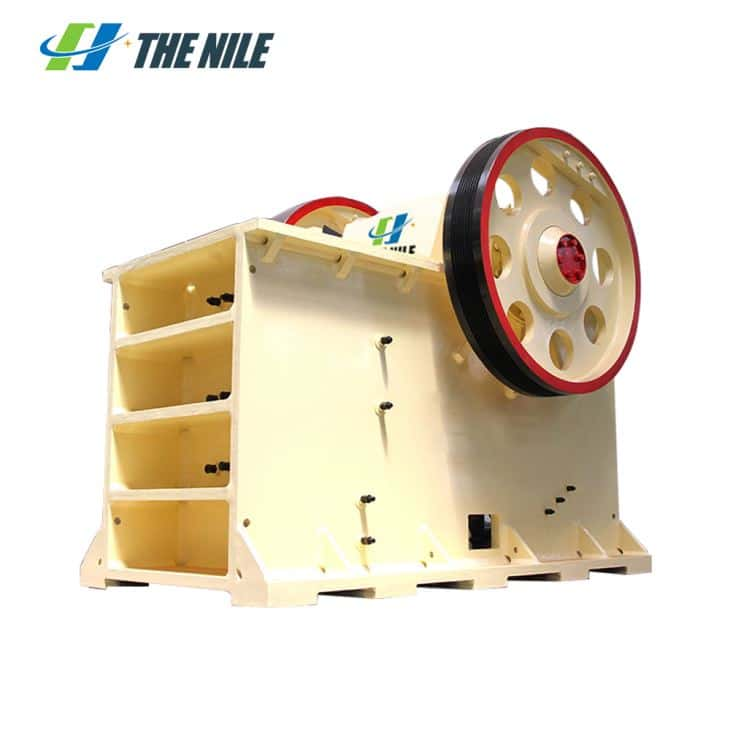

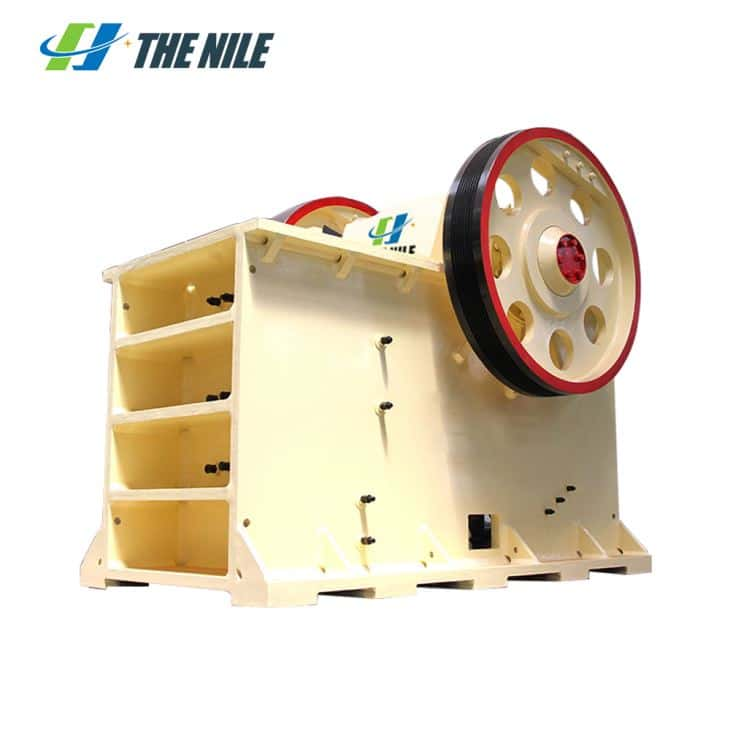

Product Description of Granite Jaw Crusher

Granite belongs to non-metallic ore. It has the characteristics of high hardness, stable chemical properties, strong wear resistance, etc. it is generally used as building materials in the construction field. Due to the large size of the unprocessed granite block, it can only be reasonably applied after crushing. The equipment for crushing granite mine is crusher, and there are many types of crushers. Among them, the granite jaw crusher is the first choice for users.

Structure Advantages of Granite Jaw Crusher

1.Large feed port, high crushing cavity, suitable for high hardness granite crushing operation, with large block size and less stone powder.

2.The gap between the mobile jaw and the static jaw of granite jaw crusher can be adjusted conveniently and effectively control the discharge particle size, which makes the finished particle shape is good to meet the needs of users.

3.The structure is compact, the machine is rigid, and the rotor of granite jaw crusher has a large moment of inertia.

4. A granite jaw crusher uses a high chromium plate hammer, which has high impact resistance, abrasion resistance, and large impact force.

Technical Parameters

Model | Max. feeding size (mm) | Discharge size (mm) | Capacity (t/h) | Motor power (kw) | Weight (t) | Diemension (mm) |

PE150*250 | 125 | 10-40 | 1-3 | 5.5 | 0.7 | 1000*870*990 |

PE250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 | 1300*1090*1270 |

PE400*600 | 340 | 40-100 | 16-60 | 30 | 7 | 1730*1730*1630 |

PE400*900 | 340 | 40-100 | 40-110 | 55 | 7.5 | 1905*2030*1658 |

PE500*750 | 425 | 50-100 | 40-110 | 55 | 12 | 1980*2080*1870 |

PE600*900 | 500 | 65-160 | 50-180 | 75 | 17 | 2190*2206*2300 |

PE750*1060 | 630 | 80-140 | 110-320 | 90 | 31 | 2660*2430*2800 |

PE900*1200 | 750 | 95-165 | 220-450 | 160 | 52 | 3380*2870*3330 |

PE1000*1200 | 850 | 195-265 | 315-500 | 160 | 55 | 3480*2876*3330 |

PEX150*750 | 120 | 18-48 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

PEX250*750 | 210 | 15-60 | 13-35 | 30 | 6.5 | 1380*1750*1540 |

PEX250*1000 | 210 | 15-60 | 16-52 | 37 | 7 | 1560*1950*1390 |

PEX250*1200 | 210 | 15-60 | 20-61 | 45 | 9.7 | 2140*2096*1500 |