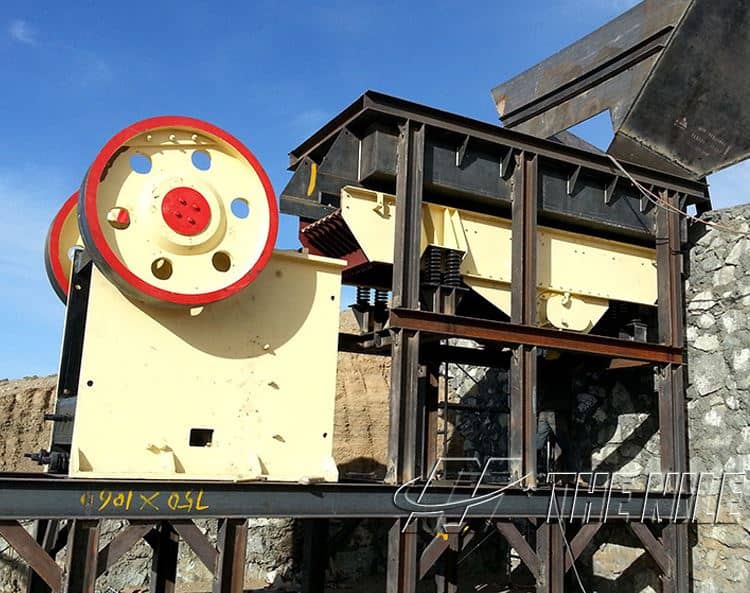

The jaw crusher is known as the "tiger's mouth". It not only has a large crushing ratio but also has a uniform crushing particle size. It is a commonly used coarse crushing equipment. The fracture of the main shaft of the jaw stone crusher is a serious problem, not only the maintenance cost is high, but also the production efficiency is affected. Today, I will give you a detailed introduction to the reasons and solutions for the fracture of the main shaft of the jaw crusher.

1. Improper speed control

The speed of the jaw crusher is too large or too small will accelerate the wear of the machine. When the speed of the machine is too large, the idling speed is also relatively high, which will affect the stability of the jaw crusher engine and accelerate the wear. When the speed of the machine is too small, it will also cause the engine to run unstable and eventually cause the machine to fail to work normally. Therefore, when operating the jaw crushing machine, we must strictly adjust the speed according to the instructions on the manual to avoid machine failure.

2. Improper operation

If the operator suddenly increases the feeding or exchanges materials with other attributes during use, the machine will not be able to temporarily control, resulting in a phenomenon of rapid and slow speed, resulting in unstable operation of the jaw stone crusher machine and accelerating the wear of the spindle. Therefore, the operator must feed evenly when feeding, and the best way is to use a feeder to feed, which is convenient and does not cause large fluctuations in the machine. Secondly, use materials of the same attribute for crushing when feeding. If you want to replace the material, replace the new material after the previous material is crushed.

3. The performance of the device itself

If the jaw crusher does not do a good job of heat treatment during the production process, it will reduce the fatigue resistance of the spindle. Once it encounters materials with high hardness or cannot be crushed, resistance will be generated, which will increase the burden on the spindle. Fracture easily occurs. In this case, we can avoid this situation by choosing experienced and well-served machinery suppliers when purchasing, and on-site inspections of the factory.

4. Unreasonable equipment structure

The unreasonable design of the spindle structure will cause the interference between the spindle and the moving cone to be too large, the filter fillet is too small, and there is no unloading groove. Some spindles with smaller widths are more prone to breakage. Therefore, when we buy machines, we still choose high-quality machinery suppliers to avoid this situation.

In general, we are looking for professional machinery manufacturers to make purchases to avoid technical problems. Secondly, we must avoid excessive feeding and speed control during operation. The most important thing is that we should pay attention to the daily maintenance and maintenance of the machine, and add lubricating oil to the parts of the machine regularly to extend the service life of the jaw stone crushing machine.