The crushed stone production line is generally used for the crushing and processing of various stones and is widely used in various construction, railway, highway, hydropower engineering, and other industries. The materials commonly used for crushing are granite, basalt, limestone, pebbles, etc. Today, I will give you a brief introduction to the equipment required for the crushed stone production line and how to configure the production equipment.

What equipment does a gravel production line generally include?

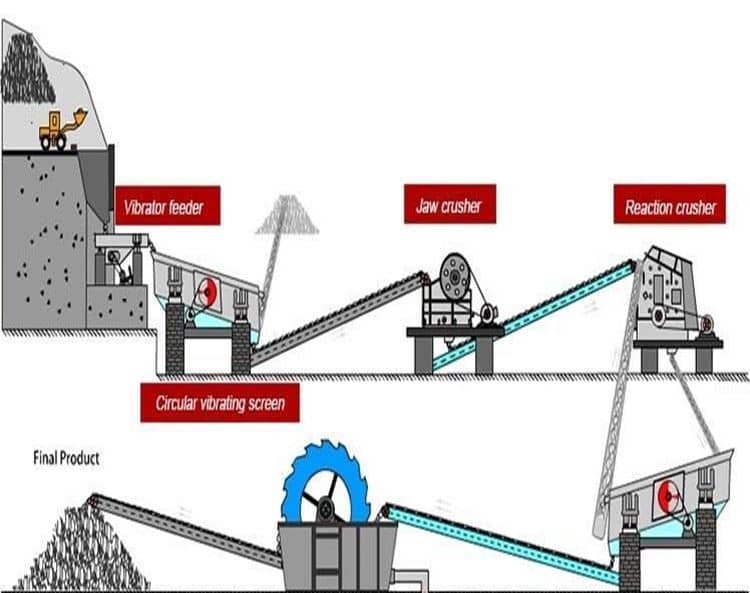

The crushed stone production line is mainly composed of feeding equipment, crushing equipment, sand-making equipment, sand washing equipment, and screening equipment. The specific configuration plan needs to be adjusted according to the characteristics of the material, the environment, and user requirements. For some stones that are not easy to move, tire-type mobile crushing stations are usually configured. The mobile crushing station integrates feeding, screening, and crushing, and can be crushed directly on-site, eliminating the need for transportation, and is flexible and convenient.

How to configure equipment for crushed stone production line

1. Consider the hardness of the material. For medium soft materials such as limestone, it is usually equipped with a jaw crusher, impact crusher, sand making machine, bucket sand washing machine, etc. Very hard materials such as basalt and pebbles are usually equipped with a cone crusher for the secondary crushing of materials with good crushing effect.

2. Consider the output of the crushed stone production line. The equipment configuration of the crushed stone production line needs to be comprehensively considered according to the hardness, water content, and processing capacity of the material, and the appropriate crushing, sand making, and screening equipment should be configured.

3. Consider the applicability and crushing ratio of the crusher. The jaw crusher adopts the principle of squeeze crushing, which has the characteristics of a large crushing ratio and uniform crushing particle size. It is generally used for the first crushing of materials. Cone crushers and impact crushers are usually used for medium and fine crushing of materials. The impact crusher adopts the principle of impact crushing, which is suitable for crushing materials with low hardness, such as quartz stone, river pebbles, limestone, and limestone. The cone crusher adopts the principle of squeezing and shearing crushing, which is suitable for crushing materials with high hardness, such as granite, basalt, and river pebbles.

4. Consider the use of stone. The impact crusher and cone crusher are both used for the secondary crushing of materials, but the requirements for the finished product are different, and the selected crushers are also different. The impact crusher breaks more and fewer grinds and has a good crushing particle shape. It is suitable for building materials and construction projects that require high finished products. Cone crusher has relatively more flake materials and is suitable for beneficiation processes that do not require high materials.

The above is a brief introduction to the commonly used equipment for gravel production, and the equipment for different materials is also different. Nile Machinery is a professional machinery supplier. If you don't know how to configure what type of equipment, you can consult our customer service online, and we will arrange professional technicians to configure reasonable equipment for you.