In the aggregate production line, crushing equipment is indispensable. So, do you know what is the commonly used coarse crushing and medium crushing equipment in the sand and gravel aggregate production line? How to choose the right crushing equipment?

Rough crushing equipment: jaw crusher, roller crusher

The jaw stone crusher has a large crushing ratio, large processing capacity (maximum processing capacity can reach 1000 t/h), low maintenance cost, and a wide application range. It can be used to crush all materials with compressive strength below 350 Mpa, such as basalt, granite, etc. Is currently the most commonly used rough breaking equipment.

The roller crusher machine can be used for coarse crushing. A medium crush can also be used for a fine crush. Although it is not as large as a jaw crusher, the roller crusher is very suitable for crushing brittle materials such as limestone, cement clinker, and feldspar.

Medium crushing equipment: impact crusher, cone crusher, hammer crusher

The impact stone crusher adopts the principle of impact crushing, and the wearing parts are highly worn. The wearing parts need to be replaced frequently in the later period, and the maintenance cost is higher than that of the cone crusher. The impact crusher machine can be used to crush hard, soft, brittle, and tough materials with high water content. It is mostly used in building materials, construction, sand and gravel aggregates, and other small and medium-sized stone factories that have strict requirements for discharge.

Cone crushers can be divided into spring cone crushers, Simmons cone crushers, horizontal bars, and multi-bar hydraulic cone crushers. The stone cone crushing machine adopts the laminated crushing principle, which is suitable for crushing various ores and rocks (river pebble, granite, basalt, etc.) with medium hardness and above; it has a variety of crushing cavity types, which can meet the production requirements of customers to the greatest extent. Achieve high yields. Compared with the impact crusher, the purchase cost is higher, but the later maintenance cost. It is suitable for large-scale stone plants that do not require high output and have large output.

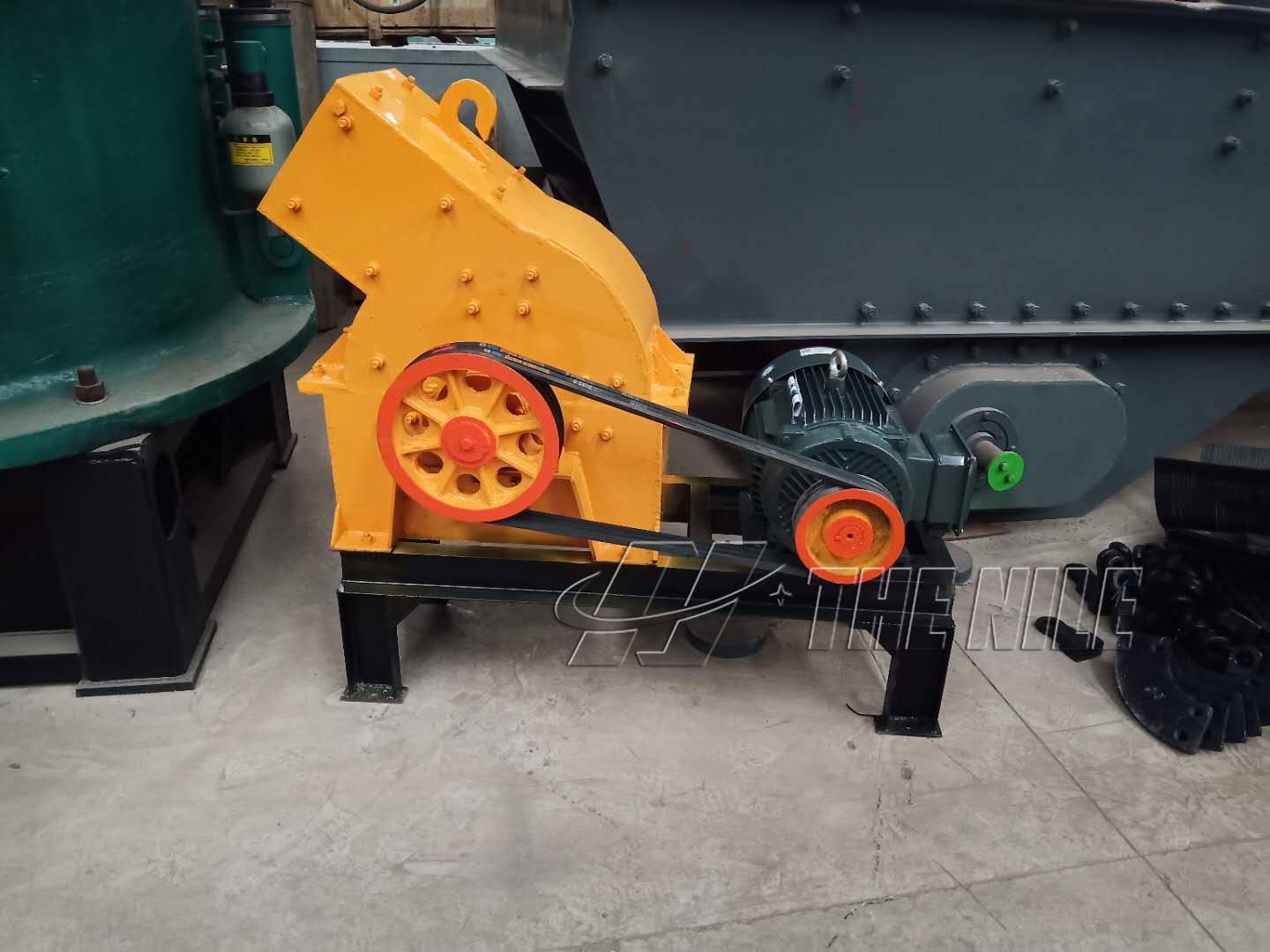

The hammer crusher adopts the principle of impact crushing and is suitable for processing medium and soft ore (limestone, coal gangue, shale, etc.).The hammer crushing machinery has the advantages of a large crushing ratio, which can be crushed and formed at one time, and the product has a good grain shape and less powder. It integrates coarse crushing and shaping functions. It has no screen plate and reduces blockage. In addition, the hammer stone crusher is also It can be used in crushing production lines, sand making production lines, and can replace cone crushers in beneficiation production lines.

The above are the commonly used crushing equipment in the sand and gravel aggregate production line. We need to choose according to the actual situation (broken materials, rock abrasiveness, finished products, output requirements, economic conditions, etc.). If you don't know how to choose, please feel free to consult online Our customer service, our customer service will arrange a professional technical team to tailor the selection and design production plan for you, so that you no longer worry about how to choose the machine.