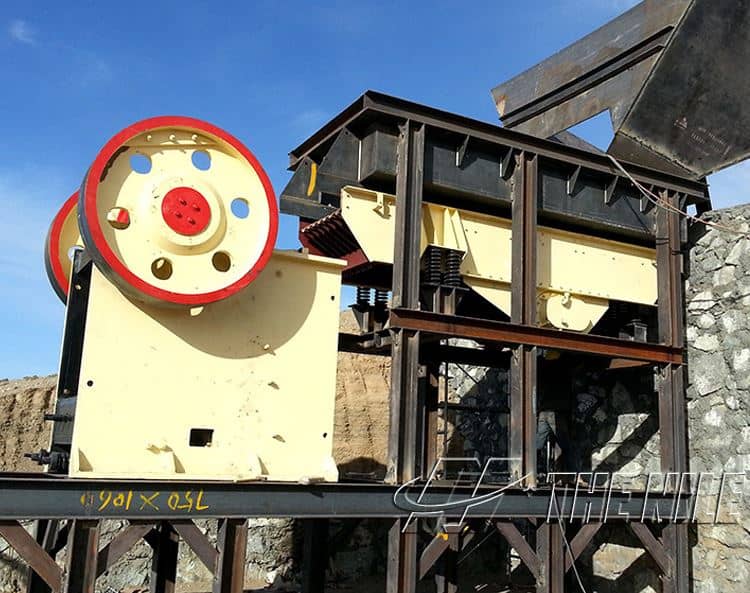

Since the jaw stone crusher works in harsh environments for a long time, it needs to crush ores and stones with higher hardness, so the parts are worn out and the wear parts need to be replaced from time to time. Just in case, we usually prepare spare parts, so do you know when the wearing parts should be replaced? How many spare parts do I need to prepare? Today, the editor will explain to you in detail.

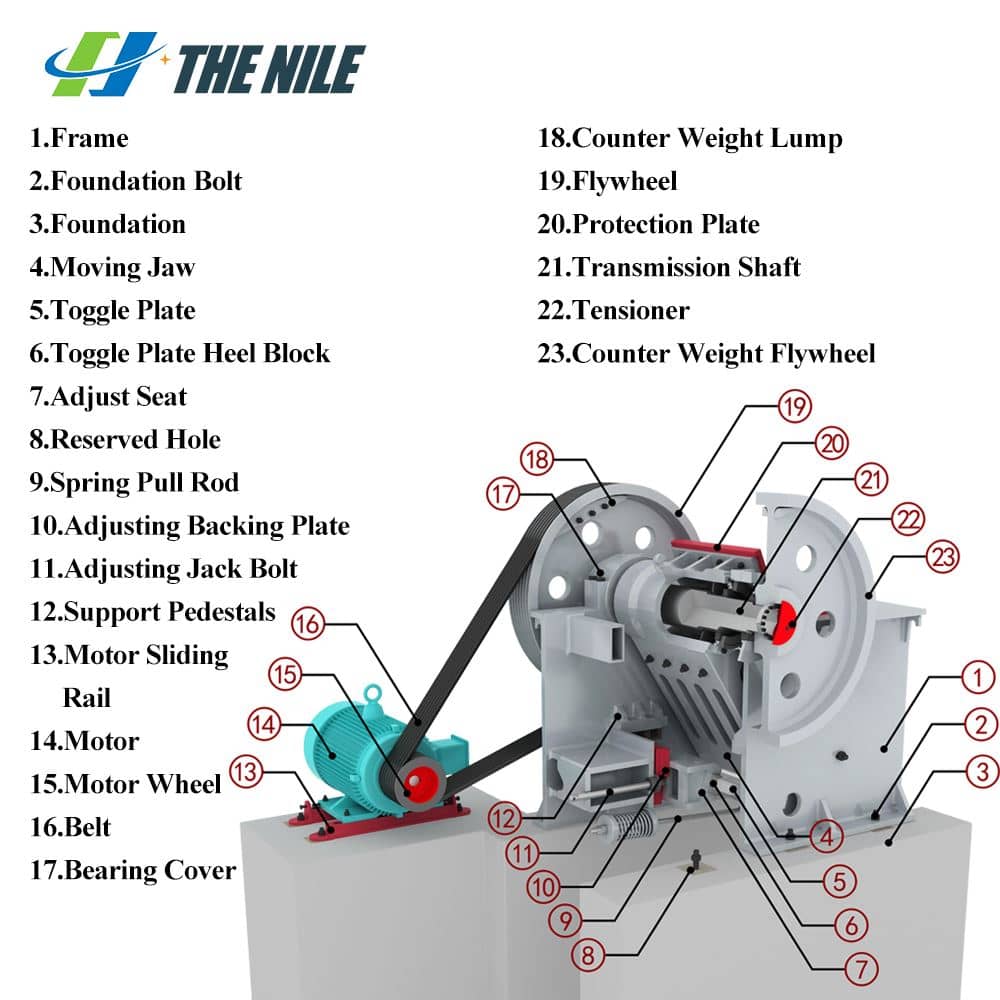

The main wearing parts of the jaw crusher machine are liner, bearing bush, toggle plate, rotation, and so on.

Liner

The fixed jaw liner (tooth plate), movable jaw liner (tooth plate), and two side liners (guard plates) of the jaw crusher are easy to wear. The faster the liner wears will affect the product specifications, and the discharge particle size will become larger. . When the liner is initially worn, the liner can be turned around, or the upper and lower parts can be turned around. The wear of the jaw plate is mostly concentrated in the middle bottom. When the tooth plate is worn out by 3/5, the liner needs to be replaced. When the plate is worn out by 2/5, it also needs to be replaced. The service life of the stone jaw crusher liner is generally 4 months. When the liner at both ends is severely worn, we must replace it in time. We can reserve 2 sets in advance for easy replacement.

Shaft, bearing bush

If the degree of shaft wear is not large and just want to repair the geometric shape, we can take a lathe for turning to make the journal to the correct geometric shape, and then reduce the bearing inner diameter accordingly. When the journal size is reduced by 5% compared to the original, a new shaft needs to be replaced. A good shaft can be used for more than half a year. We can reserve 2 pieces in advance. When the machine breaks down, we can replace it at any time without affecting the working efficiency of the machine. Since the jaw crusher works under impact load, the babbitt alloy lining on the bearing bush needs to be recast every two years.

Toggle plate

When the toggle plate of the jaw crushing machine is severely worn or broken, the stones in the crushing cavity must be removed first, and the brackets that are quickly worn or broken are removed, and then replaced with a new bracket. The service life of the bracket is generally 2 months. We can reserve 2 sets of new brackets in advance for easy replacement.

Rotation and bearing box

If the rotation and the bearing box are worn and the space exceeds 1.5 times the original installation space, it needs to be adjusted or replaced; When the oil groove is worn 1.5mm, the oil groove should be reopened and adjusted.

In addition to the above-mentioned wearing parts, there are some inconspicuous parts that also play an important role in the jaw stone crushing machinery. The service life of springs, spring pull rods, and gaskets is only half a year. You need to reserve two sets in advance and replace them at any time.

The above are some tips to improve the efficiency of the jaw crusher for sale. If you have other questions about mining machinery, please consult the online customer service, and we will arrange professional technicians to explain the solutions for you.