The stone crusher is the main equipment in the stone crushing production line. There are many types of stone crushing equipment on the market, and each type of equipment also plays a different role in the stone production line. The selection of suitable crushing and sand making equipment will greatly improve the production efficiency of the whole crushing production line. As a professional crusher manufacturer, Nile Machinery will introduce how to choose suitable crushing equipment.

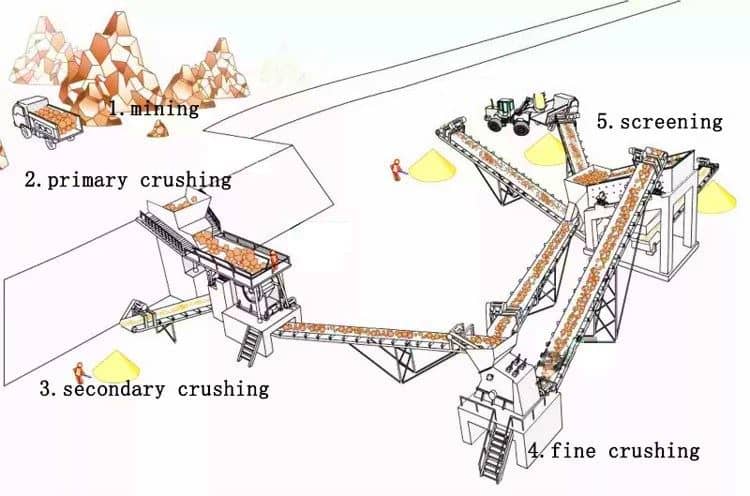

Generally speaking, a complete stone crushing production line needs to go through a series of technological processes such as primary crushing, secondary crushing, fine crushing, and screening.

Primary Crushing

In the stone crushing production line, the primary crushing is the first crushing, and the commonly used rock crushers are jaw crusher and rotary crusher. Because of its moderate price, applicable materials, output, feeding, and discharging, etc., can meet the needs of customers, so the general scale of sand and gravel plant will choose jaw crusher as coarse rock crusher plant. Large-scale sand and gravel plant customers will choose the gyratory crusher as the primary crusher. Compared with the jaw crusher, the rotary crusher has the characteristics of large volume, large weight, high output, and high investment cost, so its application range is relatively small.

Secondary Crushing

In the stone crushing production process, the stone material is crushed through the primary crushing of a gyratory crusher or jaw crusher and then enters the stone crusher machine through the belt conveyor for secondary crushing. The commonly used secondary stone crushing machines includes cone crusher, impact crusher, or hammer crusher. Among them, the cone crusher is the most widely used secondary crusher plant with the biggest advantage of large output, low energy consumption, fine crushing granularity, uniform particle size, and long service life, so the cone crusher has become the first choice for many quarries. The impact crusher and hammer crusher are also widely used because of their simple structure and low investment cost. The hammer crusher is the most suitable crusher, especially for the stone with low hardness and high brittleness. In addition, in terms of production efficiency and cost, a cone crusher is more suitable for crushing stones with higher hardness. Although the initial investment cost is higher, it can save a lot of operating costs in the long run.

Fine Crushing and Screening

After the primary and secondary crushing, the stone also needs to be finely crushed and screened. There are many types of fine crushing equipment, such as cone crusher, hammer crusher, vertical impact crusher, and so on, which have obvious advantages for fine crushing and shaping of stone. There are many different types of screening equipment, such as circular vibrating screen, linear vibrating screen, etc. Nile Machinery can customize two-layer and three-layer vibrating screens according to customers' needs, and the size range of screening can also be adjusted according to actual needs. For example, the circular vibrating screen is used to screen the materials completed by secondary crushing. Generally, the materials of 10 mm or smaller can be screened and sent to the finished material area, the materials of 10-40 mm can be screened and then sent to the fine crusher for fine crushing, and the material over 40mm is returned to the second aggregate crushing plant by the conveyor belt and crushed again.

Through the process flow of the stone crushing production line, it can be found that different rock crushing machines and screening equipment can be selected in each process.

Therefore, Nile Machinery suggests that customers choose stone crushing plant according to their own needs, such as the nature of crushed materials, output size, discharge particle size, investment budget, and the advantages of different rock crushers, so as to obtain greater benefits with the minimum investment.