Processing Materials: Stone impact crusher is used for crushing basalt, granite, pebbles, limestone, quartz, iron ore, marble, copper ore, gold ore, etc. Applied Filed: Stone impact crusher is widely used in metallurgy, building materials, ore crushing, railway, highway, energy, transportation, energy, hydropower, mining, chemical industry and other industries.

Working Principle of Stone Impact Crusher

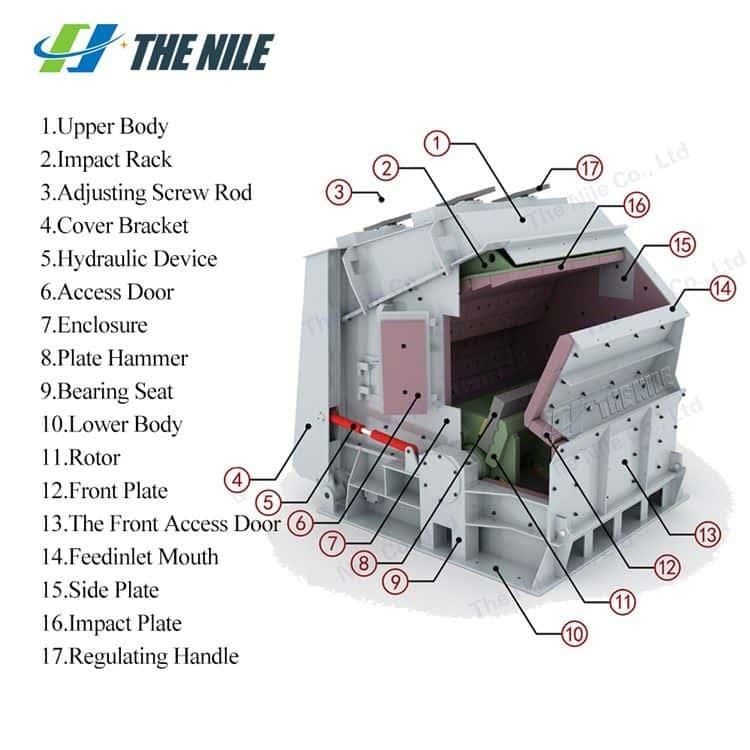

When the stone impact crusher is working, the rotor is driven by the motor and rotates at a high speed. When the material enters the action area of the plate hammer of impact crusher, it will collide with the plate hammer on the rotor of the impact crusher, and then it is thrown to the impact device for crushing again. Then, it will bounce back from the impact lining plate to the plate hammer action area for re-crushing. This crushing process is repeated, and the material will enter the first, second and third reaction cavities of the stone impact crushing plant from large to small for repeated crushing until the material is crushed to the required size and discharged from the discharge port of impact crusher station.

Advantages of Stone Impact Crusher

1.The stone impact crusher machine can effectively process the ore material with large moisture content and prevent the crusher from blocking.

2.Impact crusher machine is not only suitable for soft ore materials but also for ore materials with very high hardness.

3.The impact crusher equipment has a wide range of adjustment which can adjust the discharge particle size flexibly.

4.The vulnerable parts of the rock impact crusher have low wear and high utilization rate.

5.It's convenient to replace the spare parts of the aggregate impact crusher, which reduces the maintenance costs.

Model | Rotor Size | Feed Openning Size | Max. Feeding Size | Output Size | Capacity | Motor Power |

PF-0607 | 644*740 | 320*770 | 100 | 5-60 | 10-20 | 30 |

PF-0807 | 850*700 | 400*730 | 300 | 5-60 | 15-30 | 30-45 |

PF-1008 | 1000*800 | 400*830 | 300 | 5-60 | 30-50 | 37-55 |

PF-1010 | 1000*1050 | 400*1080 | 350 | 5-60 | 50-80 | 55-75 |

PF-1210 | 1250*1050 | 400*1080 | 350 | 5-60 | 70-120 | 110-132 |

PF-1212 | 1250*1250 | 400*1300 | 350 | 5-60 | 100-120 | 132-160 |

PF-1214 | 1250*1400 | 400*1430 | 400 | 5-60 | 130-180 | 160-200 |

PF-1315 | 1320*1500 | 680*1520 | 400 | 5-60 | 160-250 | 180-260 |

PF-1320 | 1320*2000 | 680*2030 | 400 | 5-60 | 300-350 | 300-375 |