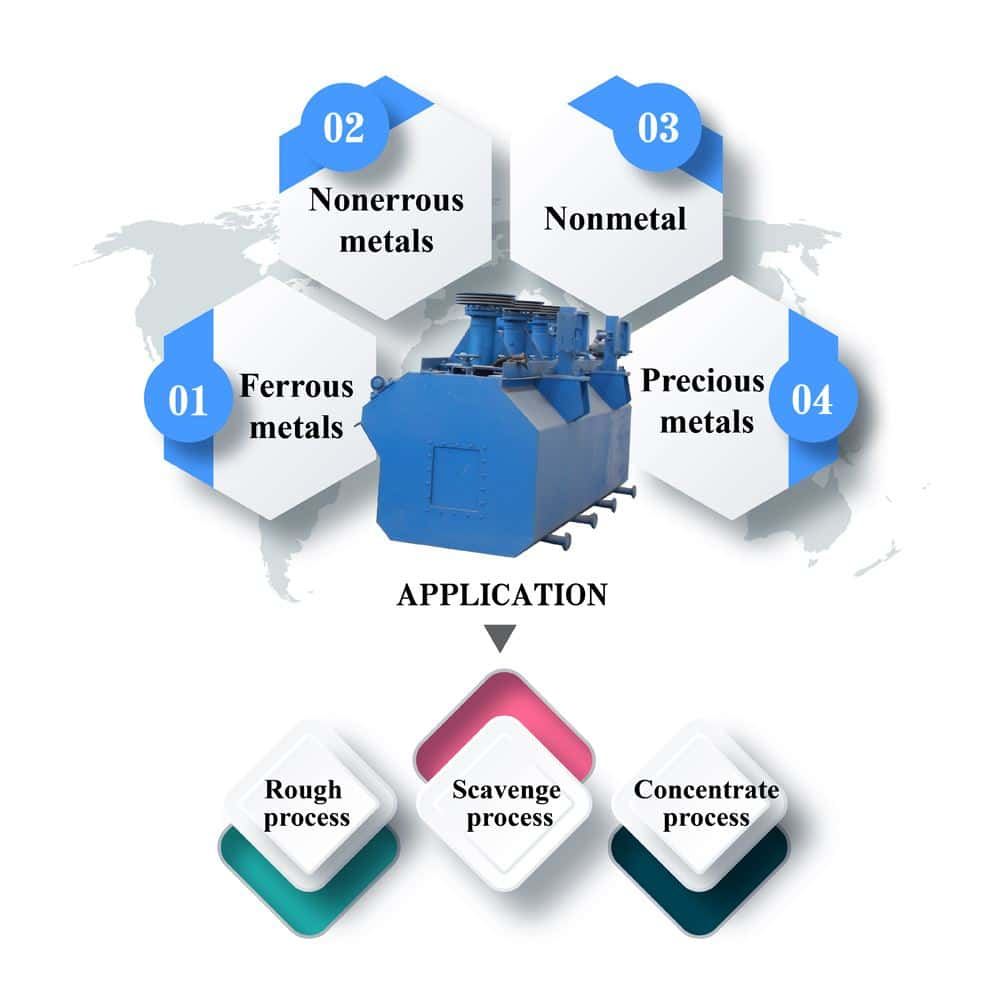

The flotation separator machine is the abbreviation of the floating concentrator, which refers to the mechanical equipment to complete the flotation process. It can be used to separate non-ferrous metals such as copper, zinc, lead, nickel, and gold, as well as for the roughing and cleaning of ferrous metals and nonmetals.

Product description

In the mineral flotation machine, the ore pulp treated by adding reagents is stirred and aerated to selectively fix some of the ore particles on the bubbles; it floats to the surface of the ore pulp and is scraped out to form a foam product, and the rest remains in the ore pulp In order to achieve the purpose of separating minerals. It is a beneficiation method with the widest application and the best effect for the sorting of fine and very fine materials.

The working principle of mechanical flotation machine

The ore flotation separator is driven by a motor V-belt and a transmission belt to rotate the impeller to produce a centrifugal effect to form a negative pressure. On the one hand, it sucks insufficient air to mix with the pulp, on the other hand, it stirs the pulp and the medicine, and at the same time refines the foam, so that the mineral is bound to the foam. It floats to the pulp surface and then forms mineralized foam. Adjust the height of the gate to control the liquid level, so that the useful foam is scraped out by the scraper.

Features of flotation mining machine:

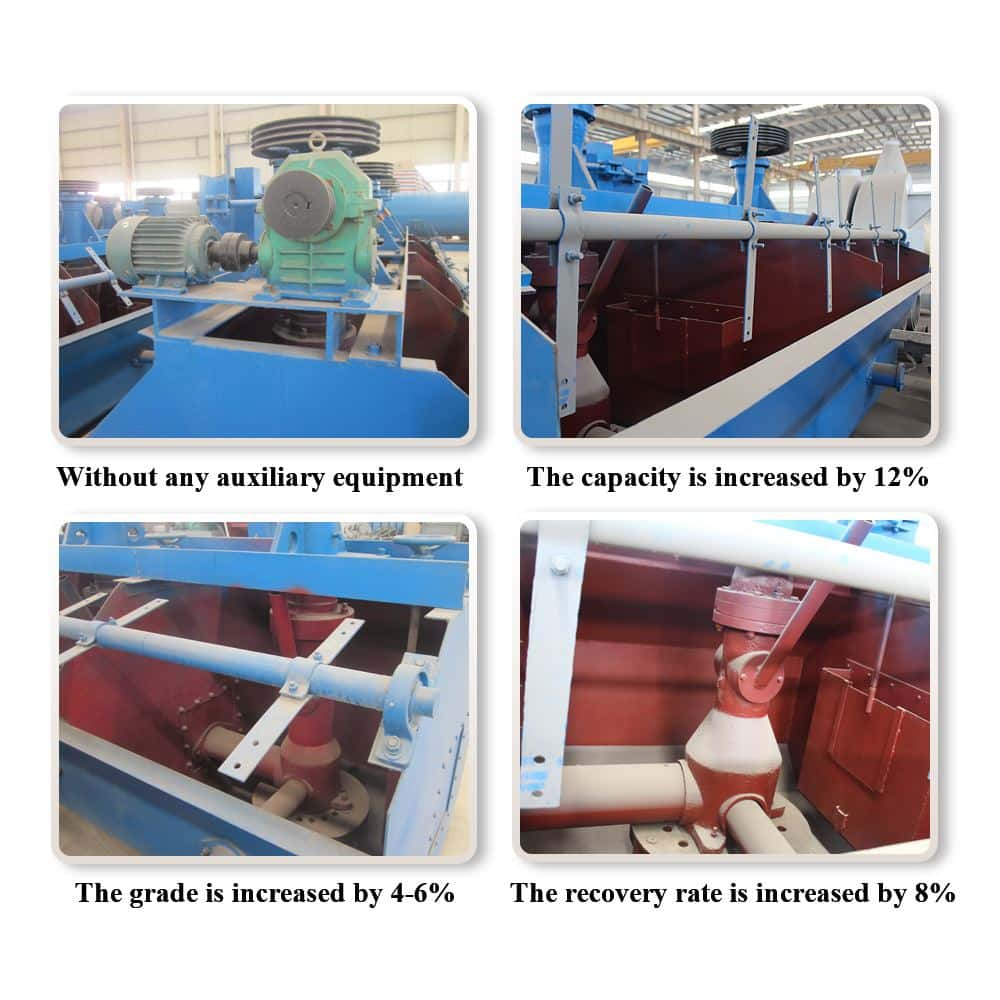

1. Long service life and low failure rate. Wearable parts such as the impeller and stator are made of wear-resistant materials, and the machine has a long service life.

2. Energy saving and high efficiency. The SF series flotation machine is more energy-saving and electricity-saving than the traditional flotation machine, and the quality flotation machine has a high degree of automation and a high degree of foam subdivision, thereby improving the flotation effect.

3. The air is evenly distributed, and the mixing effect of air and slurry is good.

4. Wide range of use. The flotation machine for minerals can be used to separate non-ferrous metals such as copper, zinc, lead, gold, etc., and can also be used for the rough selection and selection of ferrous metals and non-metals.

The structure of the industrial plant flotation machine

Flotation machines mainly include impellers, blowers, foam tanks, gates, motors, and V-belts.

Packaging and shipping

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

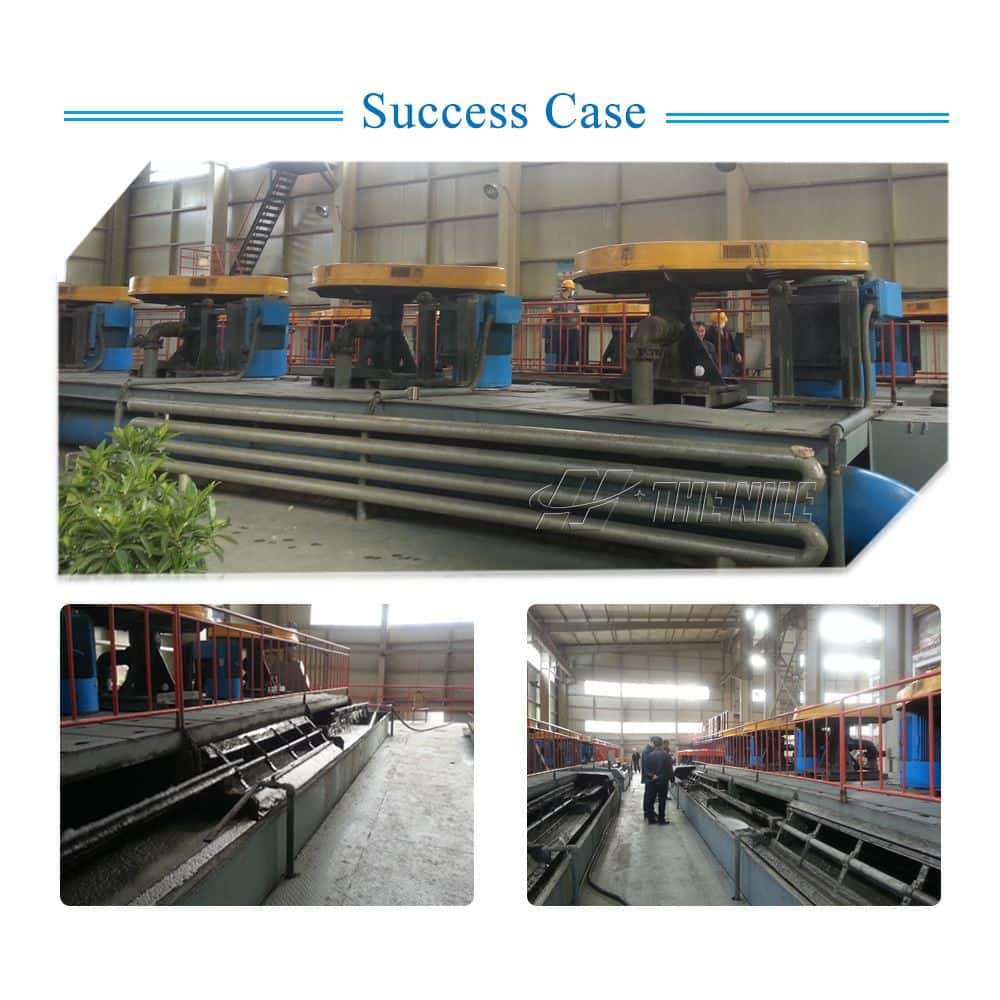

Project cases:

Production project: barite flotation production line

Production capacity: customized according to process requirements

Processing material: barite

A customer in Zimbabwe purchased two jaw crushers and a flotation device in the Nile and gained a lot of profit in the production process.

No more→

| Model | Volume (m³) | Impeller diameter (mm) | Capacity (t/h) | Power of motor(kw) | Four chutes weight(kg) | Single chute overall dimension(mm) | |

| Strring motor | Scraper motor | ||||||

| SF0.37 | 0.37 | 300 | 0.2-0.4 | 2.2 | 0.75 | 445 | 700*700*750 |

| SF0.7 | 0.7 | 350 | 0.3-1.0 | 3 | 0.75 | 600 | 900*1100*950 |

| SF1.0 | 1 | 400 | 0.45-1.1 | 5.5 | 0.75 | 978 | 1000*1000*1000 |

| SF1.2 | 1.2 | 450 | 0.6-1.6 | 5.5 | 0.75 | 1240 | 1050*1050*1050 |

| SF2.0 | 2 | 550 | 1.5-3.0 | 7.5 | 1.1 | 1879 | 1400*1400*1150 |

| SF2.8 | 2.8 | 550 | 1.5-3.5 | 11 | 1.1 | 2242 | 1600*1600*1150 |

| SF4.0 | 4 | 650 | 2.0-4.0 | 15 | 1.5 | 2660 | 1900*2000*1200 |

| SF8.0 | 8 | 760 | 4.0-8.0 | 30 | 1.5 | 4043 | 2250*2850*1400 |