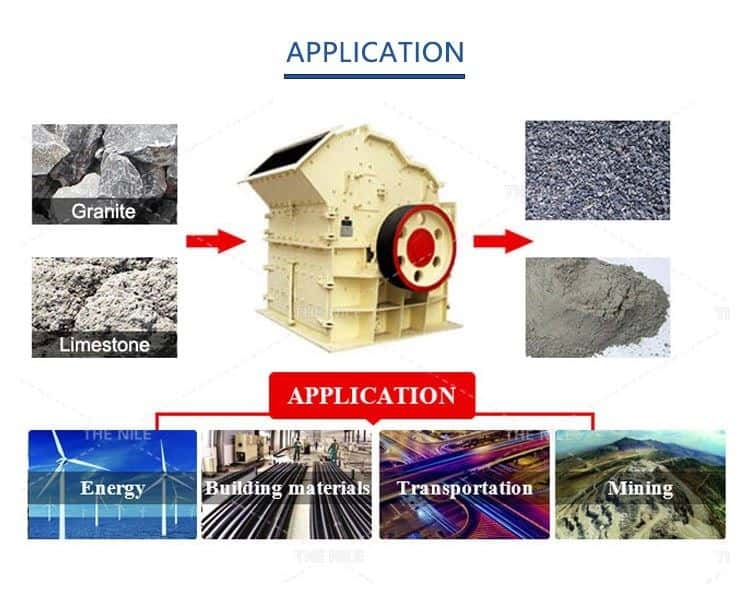

Processing Materials: Super fine crusher is a kind of energy-saving crushing equipment, which is more energy-saving than the traditional fine crusher machine. Super fine crusher machine can be widely used for materials with different properties, such as granite, quartz sand, iron ore, bauxite, steel sand, etc. Applied Field: Super fine crusher is applied in highway, building materials, transportation, chemical industry, sand production and other industries.

The Characteristics of Hammer Head of Super Fine Crusher

The hammer head is an indispensable wear-resistant accessory of the super fine crusher. The hammer head of super fine crusher is mostly made of high manganese steel, carbon steel, low alloy steel hammer head, and 26 chromium alloy casting. At present, most hammer heads are made of high manganese steel. In the production and processing, Nile Machinery add the Cr element to the high manganese steel to greatly strengthen the hammer head. When crushing iron ore, the service life of the hammer head of super fine crusher is much longer than that of ordinary high manganese steel.

The hammer head is made of high chromium cast iron, while the handle part of super fine crusher is made of high manganese steel or carbon steel, which makes it has enough strength and toughness. High chromium cast iron is a kind of material with excellent wear resistance, low tougness and easy to cause brittle fracture. Therefore, high manganese steel or carbon steel with high toughness is selected for hammer handle of super fine crusher to overcome the shortcomings of single material.

Advantages of Super Fine Crusher

1.Large production capacity and long service life of hammer head of super fine crusher.

2.The cost of long-term operation and maintenance of super fine crusher machine is lower than that of traditional process equipment of the same scale.

3.The super fine crusher can operate continuously. When working, the rotor rotates at high speed driven by the motor and the material enters the crushing cavity to be crushed, so as to achieve the crushing work.

4.The overall design of super fine crusher is beautiful in shape, compact in structure, small in weight and low in power consumption per unit product.

5.Super fine crusher has high crushing efficiency, extremely low power consumption, good dustproofness and high operation rate.

6.The hammer head of super fine crusher is made of high-quality wear-resistant alloy steel and adopts advanced casting forging processing and heat treatment process, so the service life of the parts is greatly prolonged.

Feed Size | Output Size | Capacity | Motor Power | Rotor speed | Dimension | |

800*400 | ≤120 | ≤10 | 30-40 | 37-45 | 860 | 2.1*1.4*1.7 |

800*600 | ≤180 | ≤10 | 40-50 | 45-55 | 860 | 2.1*1.62*1.7 |

800*800 | ≤180 | ≤10 | 50-70 | 45-55 | 860 | 2.1*1.84*1.96 |

1010*1010 | ≤180 | ≤10 | 60-75 | 55-75 | 720 | 2.1*1.84*1.96 |

1200*1000 | ≤180 | ≤10 | 100-110 | 90-110 | 590 | 2.45*1.6*1.96 |

1200*1200 | ≤180 | ≤10 | 120-150 | 110-132 | 590 | 3*2.16*2.5 |