Products

Home > Products > Mineral Processing Equipment > Agitator Tank

Brief Introduction: The purpose of agitator for the mineral is to add a certain amount of flocculant to the slurry to be concentrated, so as to make the ore particles in the slurry form flocs and accelerate settling speed and achieve the purpose of improving the concentration efficiency.

Technical Parameters

Model NO. | Chute size(mm) | Effective volume | Impeller | Impeller | Motor | Motor | Dimension(mm) | ||

Diameter | Height | Height | Length | ||||||

Nlh1000 | 1000 | 1000 | 0.58 | 240 | 530 | Y100l-6 | 1.5 | 1300 | 685 |

Nlh1500 | 1500 | 1500 | 2.2 | 400 | 320 | Y132s-6 | 3 | 1690 | 861 |

Nlh2000 | 2000 | 2000 | 5.6 | 550 | 230 | Y132m2-6 | 5.5 | 2381 | 1240 |

Nlh2500 | 2500 | 2500 | 11.2 | 630 | 230 | Y160l-6 | 11 | 2881 | 3462 |

Nlh3000 | 3000 | 3000 | 19.1 | 700 | 210 | Y225s-8 | 18.5 | 3266 | 4296 |

Working Principle of Agitator for Mineral

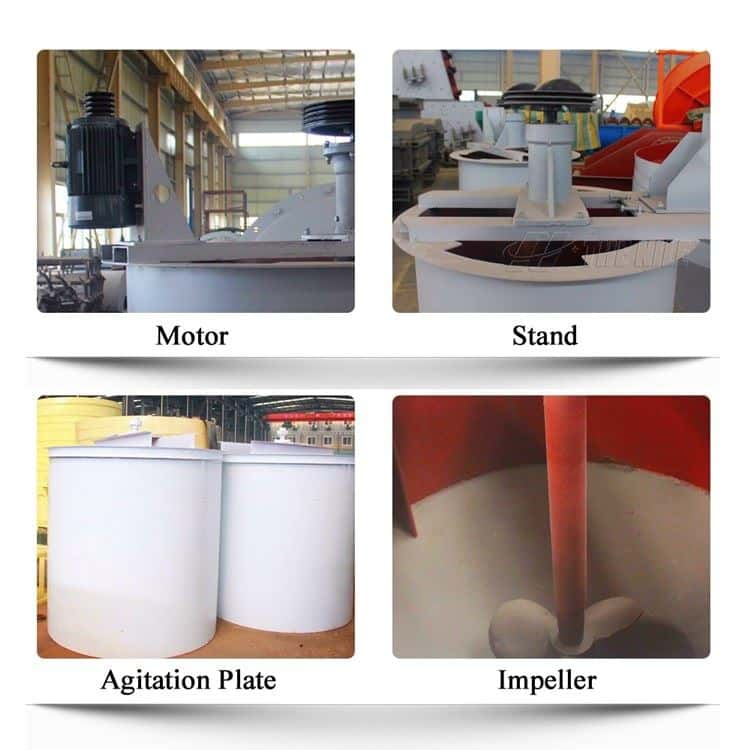

The mining mixer is driven by the motor V-belt to drive the impeller to rotate, which fully mixes the medicine and the slurry uniformly increases the reaction time of the medicine and enhances the quality of the medicine reaction.

Main Features of Agitator for Mineral

1.The whole equipment is made of stainless steel and equipped with movable baffle, which is convenient for feeding.

2.The stirring spindle can adopt fixed speed and frequency conversion speed adjustment according to user requirements, with uniform mixing, no precipitation, and no accumulation, and can achieve full and uniform stirring of the slurry.

3.The pneumatic diaphragm pump uses compressed air as the power source, which can be used to transport all kinds of materials with high content and strong wear-resistant particles, so as to realize the extraction, transportation, and transfer of slurry.

4.Adopting a circulating filtration pipeline system, which can realize the three functions of mortar filtration, mortar output, and glycol input respectively, and the compressed air is also used to clear the pipeline.

5.When the machine is working and mixing, the material in the machine is under the action of the rotor and the baffle to perform the compound movement, and the material for the blade belt rotates along the inner wall of the machine tank. This enables the material to continuously circulate in the machine tank, so as to achieve a soft, fast, and uniform effect.

Technical Parameters of Agitator for Mineral

Model NO. | Chute size(mm) | Effective volume | Impeller | Impeller | Motor | Motor | Dimension(mm) | ||

Diameter | Height | Height | Length | ||||||

Nlh1000 | 1000 | 1000 | 0.58 | 240 | 530 | Y100l-6 | 1.5 | 1300 | 685 |

Nlh1500 | 1500 | 1500 | 2.2 | 400 | 320 | Y132s-6 | 3 | 1690 | 861 |

Nlh2000 | 2000 | 2000 | 5.6 | 550 | 230 | Y132m2-6 | 5.5 | 2381 | 1240 |

Nlh2500 | 2500 | 2500 | 11.2 | 630 | 230 | Y160l-6 | 11 | 2881 | 3462 |

Nlh3000 | 3000 | 3000 | 19.1 | 700 | 210 | Y225s-8 | 18.5 | 3266 | 4296 |