Products

Home > Products > Mineral Processing Equipment > Agitator Tank

Applied Field: Agitator is a mineral processing equipment improved by introducing foreign advanced technology and combining with domestic market. It is suitable for mixing and leaching materials in gold mining, metallurgy, chemical and other industries.

Technical Parameters

Model NO. | Chute size(mm) | Effective volume | Impeller | Impeller | Motor | Motor | Dimension(mm) | ||

Diameter | Height | Height | Length | ||||||

Nlh1000 | 1000 | 1000 | 0.58 | 240 | 530 | Y100l-6 | 1.5 | 1300 | 685 |

Nlh1500 | 1500 | 1500 | 2.2 | 400 | 320 | Y132s-6 | 3 | 1690 | 861 |

Nlh2000 | 2000 | 2000 | 5.6 | 550 | 230 | Y132m2-6 | 5.5 | 2381 | 1240 |

Nlh2500 | 2500 | 2500 | 11.2 | 630 | 230 | Y160l-6 | 11 | 2881 | 3462 |

Nlh3000 | 3000 | 3000 | 19.1 | 700 | 210 | Y225s-8 | 18.5 | 3266 | 4296 |

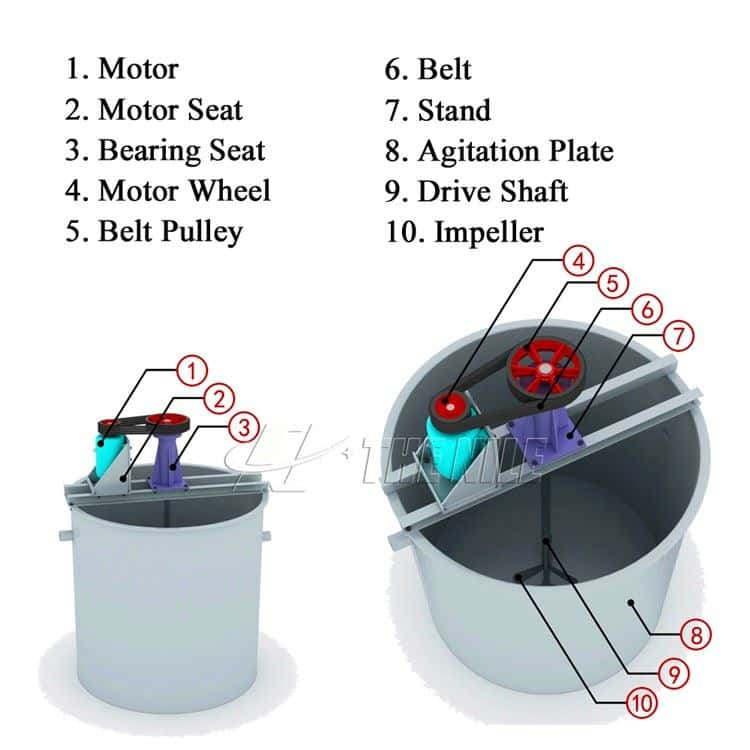

Working Principle of Agitator

Driven by the double impeller, the slurry flows from top to bottom of the center and diffuses to the surrounding mud baffles. Air is fed from the hollow shaft to mix with the slurry and circulate upwards to promote the refinement of bubbles, forming a suspension mixture with high leaching rate.

Advantages of Agitator

Agitator has the advantages that continuous work, simple operation, flexible process combination with large or small scale, and more preferably high leaching rate and high resource utilization.