Applied Field: Raymond mill is the common grinding equipment for grinding barite, calcite, potash feldspar, talcum, marble, limestone, ceramic and slag below scale 7 of moth's hardness and 6% humidity non-flammable and non-explosive stuff etc which include 280 odds of raw material from mining, metallurgy, building material and chemical industry for power generation and processing. The product size is adjustable on required in the range of 40-400 meshes and some of them up to 2500 mesh.

5. Excellent sealing

Technical Parameter

Model | Roller Number | Roller Size | Feeding Size | Output Size | Capacity | Motor Power | Weight |

3R1510 | 3 | 150*100 | 15 | 0.2-0.044 | 0.3-1.2 | 7.5 | 2 |

3R2115 | 3 | 210*150 | 15 | 0.2-0.044 | 0.4-1.6 | 15 | 3.6 |

3R2615 | 3 | 260*150 | 20 | 0.2-0.044 | 0.8-2.5 | 18.5 | 4.2 |

3R2715 | 3 | 270*150 | 20 | 0.2-0.044 | 0.9-2.8 | 22 | 4.8 |

3R2715 | 3 | 300*150 | 20 | 0.2-0.044 | 1.2-3.5 | 30 | 5.3 |

4R3016 | 4 | 300*160 | 20 | 0.2-0.044 | 1.2-4 | 30 | 8.5 |

4R3216 | 4 | 320*160 | 25 | 0.2-0.044 | 1.8-4.5 | 37 | 15 |

5R4121 | 5 | 410*210 | 30 | 0.2-0.044 | 3-9.5 | 75 | 24 |

Working Principle of Raymond Mill

Firstly, the raw material is crushed by jaw crusher to the required size of Raymond mill and lifted up to the hopper. Secondly, the raw material goes into the grinding cavity through the vibrating feeder at an even rate. Thirdly, the raw material lifted by the shovel is ground into powder between the ring and roller of Raymond mill. Fourthly, the powder is blown up to the cyclone collector through the classifier and collected through the discharging valve. The powder which cannot go through the classifier will be reground into the needed powder.

Features of Raymond Mill

1. Under the same power condition, the output of raymond mill increases by 10% - 20%.

2. Good dustproof effect, which meets the requirements of national dust-dump standard.

3. The whole system is composed of some independent systems, and the cohesion between the systems is very good.

4. The important parts of Raymond mill are made of high-quality steel, and the wear parts are made of high-performance wear-resistant materials. The electric system of rod mill adopts centralized control, and the grinding workshop can basically realize unmanned operation and convenient maintenance.

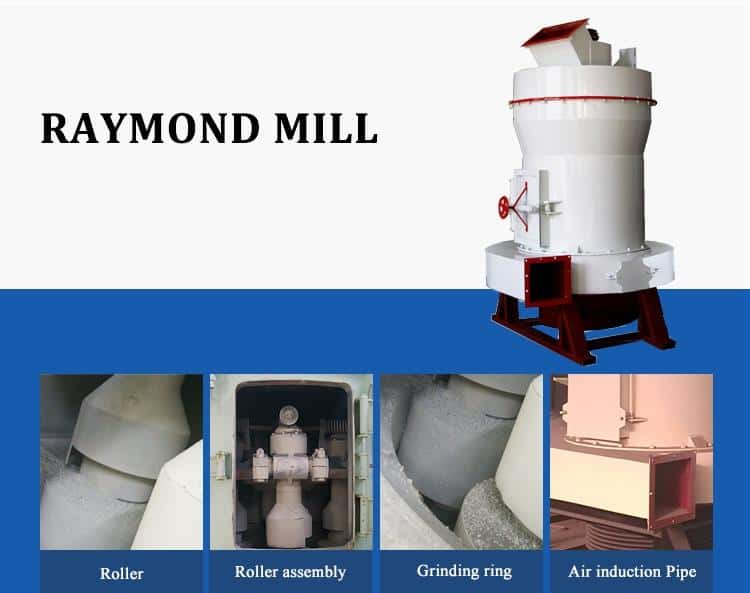

Details of Wearing Parts of Raymond Mill

Packing&Shipping

Standard package in export containers

FAQ

Q1: If you can help to make the flowchart?

A: Yes, sure. We've will make the flowchart design according to each client's mineral situation, totally for FREE!Moreover, our engineer can go abroad to guide the installation.

Q2: Service and Payment Terms?

A: We can accept T/T and L/C, 30% deposit, and 70% balance before delivery, which is international trade practice. Finished product pictures will provide to customers before delivery.

Q3: Hi, do you have an overseas factory?

A: Yes, we already have warehouses and stock in Kenya, Sudan, agents in Tanzania, Zambia, etc.

Model | Roller Number | Roller Size | Feeding Size | Output Size | Capacity | Motor Power | Weight |

3R1510 | 3 | 150*100 | 15 | 0.2-0.044 | 0.3-1.2 | 7.5 | 2 |

3R2115 | 3 | 210*150 | 15 | 0.2-0.044 | 0.4-1.6 | 15 | 3.6 |

3R2615 | 3 | 260*150 | 20 | 0.2-0.044 | 0.8-2.5 | 18.5 | 4.2 |

3R2715 | 3 | 270*150 | 20 | 0.2-0.044 | 0.9-2.8 | 22 | 4.8 |

3R2715 | 3 | 300*150 | 20 | 0.2-0.044 | 1.2-3.5 | 30 | 5.3 |

4R3016 | 4 | 300*160 | 20 | 0.2-0.044 | 1.2-4 | 30 | 8.5 |

4R3216 | 4 | 320*160 | 25 | 0.2-0.044 | 1.8-4.5 | 37 | 15 |

5R4121 | 5 | 410*210 | 30 | 0.2-0.044 | 3-9.5 | 75 | 24 |