The jigging separator machine uses water as the mineral medium and can separate the ore from the gangue according to the weight ratio. Diaphragm, stroke, and stroke frequency can be flexibly adjusted, and are used for gravity processes of tungsten, hematite, tin, gold, magnetite, manganese, and lead.

Product description

jigging machine is an energy-saving gravity sorting equipment developed and improved on the basis of traditional jigging machine according to the theoretical layering rules of jigging machine. The jigging pulsation curve of the sawtooth wave jigging machine is sawtooth. , Which makes the ascent faster than the descending water flow: the ascent time is shorter and the descending time is longer. The jig separator machine can be used for the rough selection and beneficiation of most minerals and has been widely used in the field of manganese ore and barite beneficiation.

Working principle of jig machine

The working principle of the jigging equipment is an energy-saving gravity separation equipment developed and improved on the basis of the traditional jig and according to the theoretical layering rules of the jig. The materials are mainly sorted according to the density difference in the vertical lifting and variable-speed medium flow.

Features of jigging machine for sale

1. Convenient installation, simple operation, and easy maintenance.

2. The pulsation curve of the jig separator equipment makes it easier for heavy mines to sink.

3. The jig machine improves the looseness of the bed, reduces the suction effect, enables the heavy mineral particles in the mineral to fully settle, and greatly improves the equipment's mineral processing capacity and recovery rate.

4. Less water consumption and small floor space.

5. The jigging machine is driven by the cam mechanism, and the sawtooth waveform pulsating curve is produced, effectively improving the recovery rate of fine-grained effective minerals.

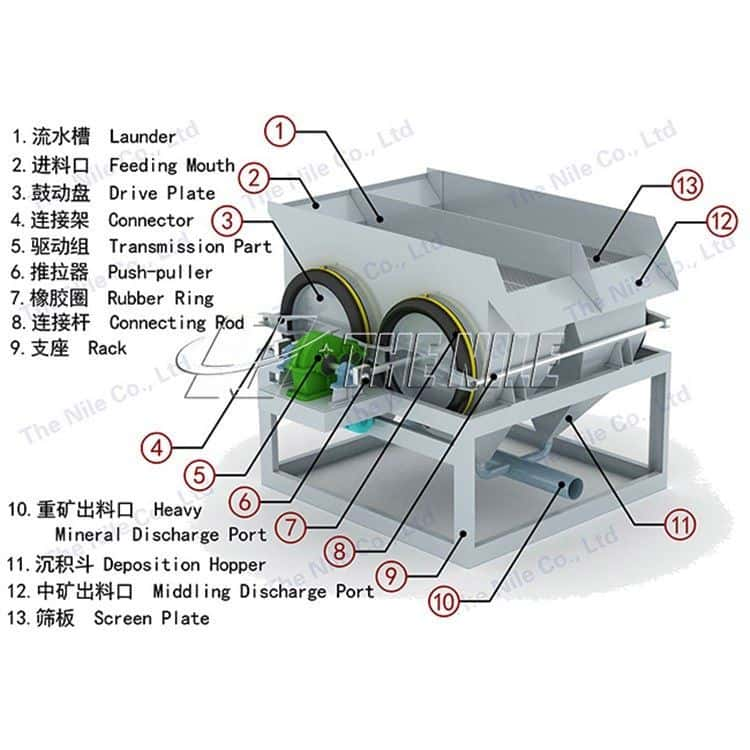

The structure of the mining jigging separator

The gold jigging machine is mainly composed of a box, a motor, a diaphragm, a cone, a spring, a feed port, and a discharge port.

Raw material production process display

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

Project case: Kenyan jig selection fluorite mine site

Processing materials: fluorite ore

Output: 20 t/h

Equipment configuration: JT5-2

Product details: A customer in Kenya wants to buy a machine for processing fluorite ore. Under the advice of the Nile Technology Department, he bought a JT5-2 type jigging machine. The beneficiation effect is remarkable, and the customer is Praise

No more→

| Model | Jigging chamber(pcs) | Feed size(mm) | Stroke(mm) | Time/min | Capacity(t/h) | Power(kw) |

| JT-0.57 | 1 | 6 | 12,17,21 | 80-180 | 1-2.5 | 1.5 |

| JT1-1 | 1 | <10 | 12,17,21 | 80-180 | 2-3 | 2.2 |

| JT2-2 | 2 | <10 | 12,17,21 | 80-180 | 4-8 | 3 |

| JT3-1 | 1 | <10 | 10-47 | 50-125 | 6-10 | 5.5 |

| JT4-2 | 2 | <10 | 10-30 | 50-125 | 10-15 | 7.5 |

| JT5-2 | 2 | <10 | 15,20,25 | 50-125 | 12-20 | 7.5 |