Products

Home > Products > Mineral Processing Equipment > Jig Machine

Applied Field: Jig concentrators are mostly hydraulic jigging. Jig concentrators is often used for the beneficiation of tungsten, tin and other non-ferrous metal ores. The larger the relative density difference of ore particles is, the smaller the difference in particle size is and the better the separation effect is.

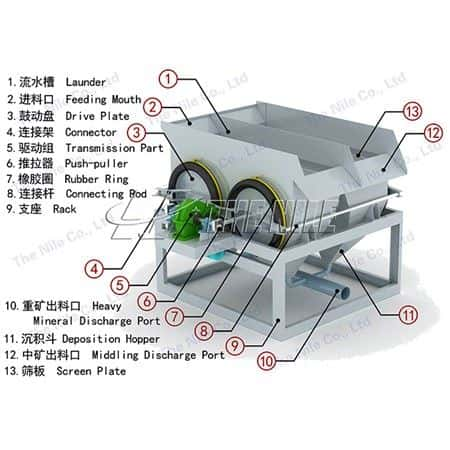

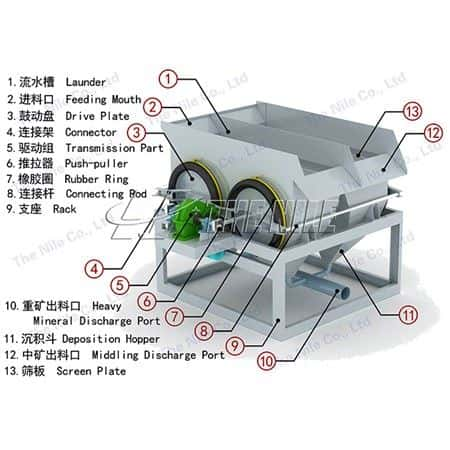

Working Principle of Jig Concentrators

Jig concentrator refers to a process in which materials are sorted according to the density difference in the vertical rising variable speed medium flow. The selected material is fed to the sieve plate of the jig concentrator to form a dense material layer, which is called the bed layer. The main internal reason for the stratification of materials in the jigging process is the nature of the mineral particles, but the objective condition for the realization of stratification is the vertical ascending and descending alternating water flow.

Jigging Concentrators Process

There are many factors that affect the jig concentrator process, including material properties, mechanical structure, and operation factors. For certain materials and jigs, determining a reasonable operation system is the guarantee to obtain a good separation effect.

1. Feeding of jig machine

2. Jigging frequency and amplitude

3. Air and water volume

Technical Parameters of Jigging Concentrators