Product Description Jaw crusher set has charateristics of high crushing ratio, simple structure, reliable operation, easy maintenance, economical operating cost etc. Jaw crusher set is widely used in mining, smelting, buliding material, highway, railway, conservancy, chemical industry and many...

Product Description

Jaw crusher set has charateristics of high crushing ratio, simple structure, reliable operation, easy maintenance, economical operating cost etc. Jaw crusher set is widely used in mining, smelting, buliding material, highway, railway, conservancy, chemical industry and many other sectors with compression strength less than 350MPA.

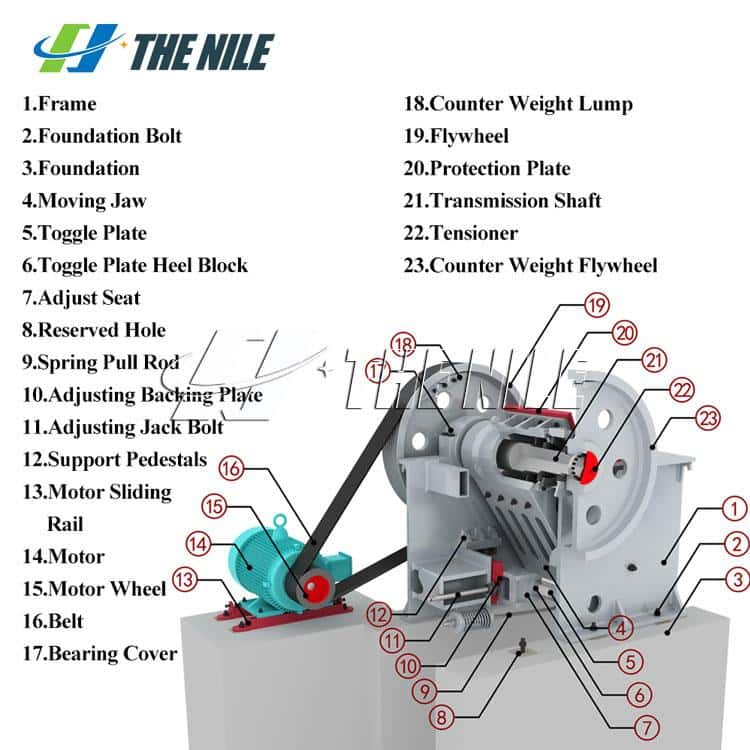

Working principle

Jaw crusher set uses compressive force for breaking material.The swingjaw of the jaw crusher moves up and down around the eccentric shaft. When the moving jaw rises, the material is crushed by extrusion, splitting and impact between the two jaw plates; when the moving jaw goes down, the moving jaw plate leaves the fixed jaw plate, and the crushed material is discharged from the lower opening of the crushing chamber.As the motor rotates continuously, the crushing maneuvering cycle motion crushes and excretes the material to achieve continuous production.

Popular Applications for Jaw Crushers

Jaw crusher setcan be used duringthe first stage and secondstage crushing unit. The Jaw Crusher is well suited for a variety of applications, including rock quarries, sand and gravel, mining, construction and demolitionrecycling, construction aggregates, road and railway construction, metallurgyand water conservancy.

Benefits ofJaw Crushers

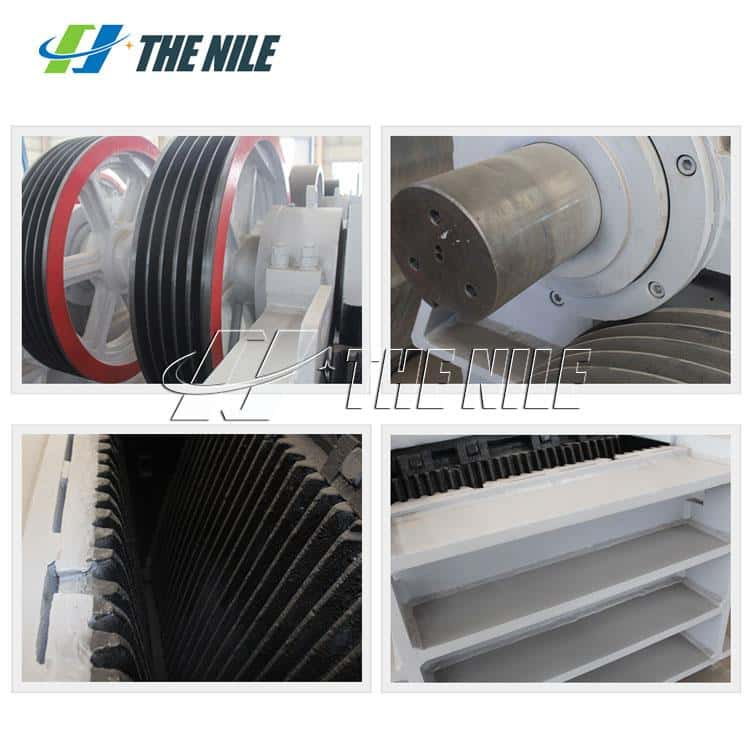

Open back for easilymaintenance

Deep crushing cavity and energy efficiency

Strong stability, long service life

Wide range of the discharging adjustment and multi-purpose

Simple operation, convenient maintenance

Low noise and dust

High crushing efficiency

High wear-resistant plates and protection plates

Widely used for crushing process of various metal ores and non-metal ores

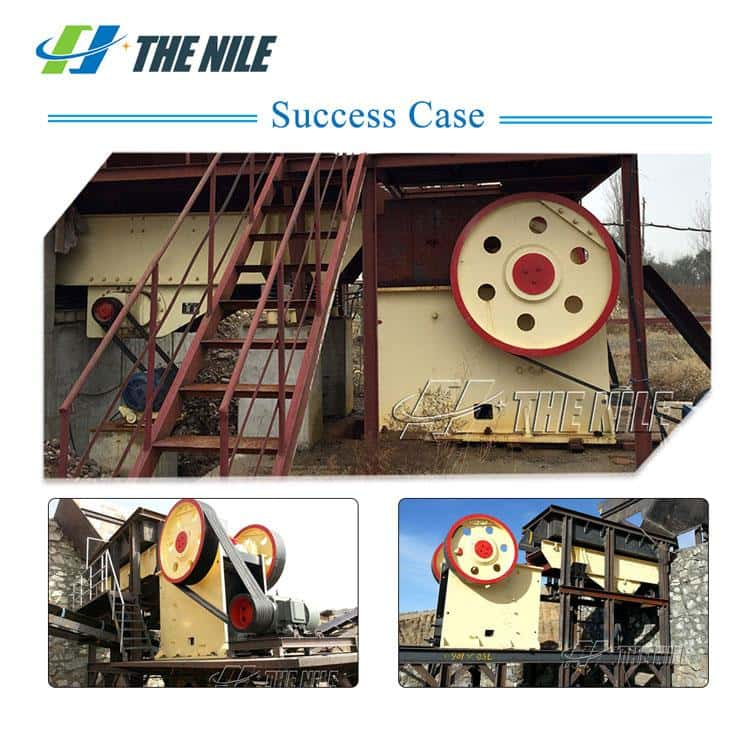

Product Cases

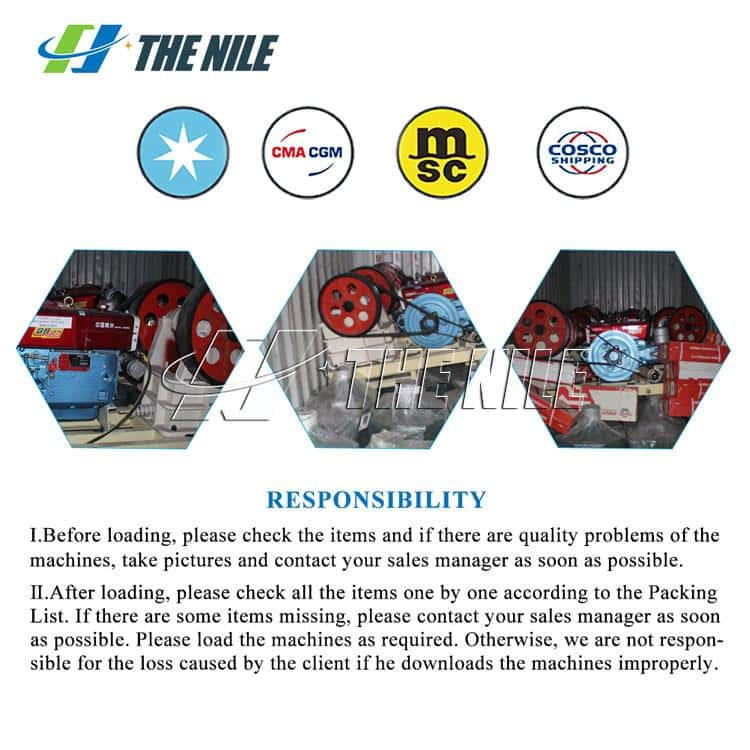

Packaging & Shipping

Company Information

The Nile Co.,Ltd.is committed to designing,producing grinding mills,crushers,conveyors,feeding machine,drying and calcinating as well as beneficiation equipments,fine sand recyling equipment etc,which are widely applied in electricity,metallurgy,mine and quarry ,wharf,granary,chemical industry.Our products have been spreaded all over China,and also exported to

European,American,Asian,African countries and enjoyed great popularity among our customers.

Our company owns an experienced and skilled sales and service team which compose a perfect service network.We will send the professional engineers to the installation sites and provide guidance for the installation,commissioning and initial run as well as planning administration of the equipments after purchase.

Our Customers

Model | Max. feeding size (mm) | Discharge size (mm) | Capacity (t/h) | Motor power (kw) | Weight (t) | Diemension (mm) |

PE150*250 | 125 | 10-40 | 1-3 | 5.5 | 0.7 | 1000*870*990 |

PE250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 | 1300*1090*1270 |

PE400*600 | 340 | 40-100 | 16-60 | 30 | 7 | 1730*1730*1630 |

PE400*900 | 340 | 40-100 | 40-110 | 55 | 7.5 | 1905*2030*1658 |

PE500*750 | 425 | 50-100 | 40-110 | 55 | 12 | 1980*2080*1870 |

PE600*900 | 500 | 65-160 | 50-180 | 75 | 17 | 2190*2206*2300 |

PE750*1060 | 630 | 80-140 | 110-320 | 90 | 31 | 2660*2430*2800 |

PE900*1200 | 750 | 95-165 | 220-450 | 160 | 52 | 3380*2870*3330 |

PE1000*1200 | 850 | 195-265 | 315-500 | 160 | 55 | 3480*2876*3330 |

PEX150*750 | 120 | 18-48 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

PEX250*750 | 210 | 15-60 | 13-35 | 30 | 6.5 | 1380*1750*1540 |

PEX250*1000 | 210 | 15-60 | 16-52 | 37 | 7 | 1560*1950*1390 |

PEX250*1200 | 210 | 15-60 | 20-61 | 45 | 9.7 | 2140*2096*1500 |