Part 1

Mainly suitable for building materials, transportation, energy, cement, mining, chemical, and other industries

Working principle:

The high-speed impact material of the plate hammer causes the broken material to be continuously thrown to the counterattack device installed above the rotor, and then it springs back from the counterattack liner to the action area of the plate hammer to be counterattacked again until the material is broken to the required size.

Maximum feed size:

Feeding size≤400mm

Part 2

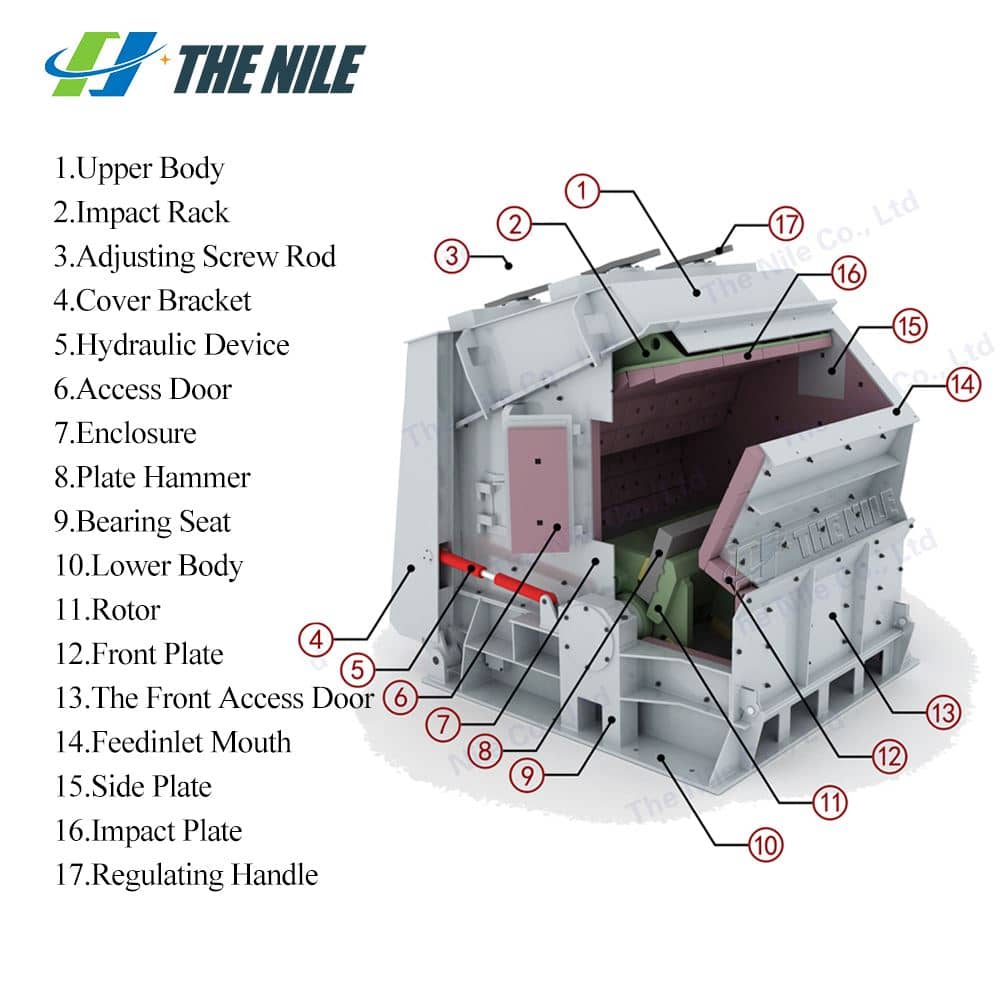

structural composition: Rotor, counterattack frame, frame, and rotating parts, and other components

Back rack: The three counterattack frames are all spring structures. Each strike rack is individually supported on the crusher rack. When the crusher is working, the counterattack frame maintains its normal working position by the constant pressure of self-weight and spring; The clearance between the impact frame and the rotor can be adjusted by suspension bolts, and the clearance of the third impact plate can be adjusted by adding or reducing gaskets. Counterattack liners can be replaced from areas of greater wear to areas of lesser wear

Rotor: The rotor is composed of: bearing, bearing chamber, plate hammer, block, stop iron, inner and outer gland, sealing ring, and so on. The plate hammer is the most easily worn part in counterattack breaking, which is fixed to the rotor by wedges

General working process

Stone→Hammer→Back rack→Hammer→Back rack (Discharge/Repeat)

Part 3

easily damaged parts: Plate hammer, lining plate, counter plate, spring, bearing, etc