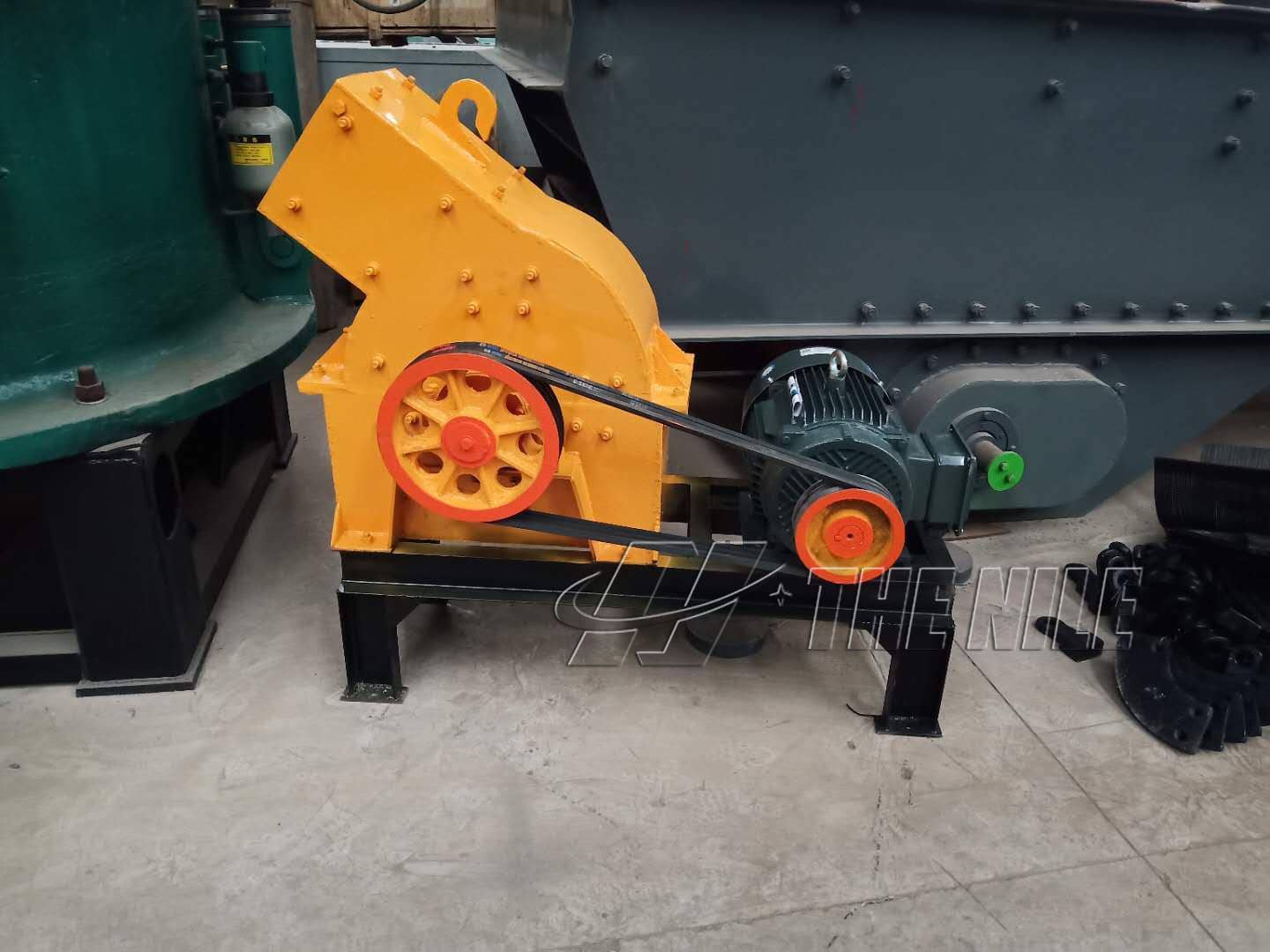

Hammer crusher is a commonly used crushing equipment, the hammerhead will inevitably be worn out, but if the hammerhead wears severely, it will not only affect the work efficiency but also increase the cost of replacing the hammerhead, so we must consider the machine before buying the machine Whether the hammerhead is durable. The main factors affecting the wear of the hammerhead are the material of the hammerhead, the hardness of the crushed material, the manufacturing quality of the hammerhead itself, the structural design of the hammerhead, and the speed of the crusher rotor.

1. The material of the hammer

Before purchasing a hammer stone crusher, we can choose a hammer crusher manufacturer with a composite hammerhead. Generally, the hammerhead is made of high-hardness and high-melting cast iron, and the hammer handle is made of high-toughness alloy steel. The combination of the two not only makes the head of the hammerhead high in hardness but also makes the hammer handle high in toughness. It can give full play to the advantages of the two materials and overcome the shortcomings of a single material to meet the performance requirements of the hammerhead. Extended service life.

2. The hardness of the crushed material

The hammer crusher machine is suitable for crushing materials with medium hardness and weakly corrosive materials, and the compressive strength cannot exceed 100MPa, such as limestone, slag, coke, coal, and other materials. If the crushing hardness is too large, it will accelerate the wear of the hammer. In addition, the hammer can not crush materials with a water content of 15% or more. The excessive water content will cause the materials to stick together, causing material accumulation and aggravating the wear of the hammer.

3. The manufacturing quality of the hammer itself

The manufacturing process of the hammerhead is the key factor that determines the service life of the hammerhead of the crusher. If there are defects on the surface or internal manufacturing of the hammerhead (such as keyholes, crystal penetration, cracks, etc.), it will not only reduce the performance of the hammerhead but even cause the hammerhead to break and affect production. Therefore, when choosing a machine manufacturer, you must choose a professional and experienced manufacturer, and inspect the factory on the spot, and finally decide whether to buy it.

4. The structure design of the hammerhead

Since the internal wear resistance of the hammerhead is significantly lower than the surface, for a hammerhead with a larger thickness, it is best for us to optimize the structure of the hammerhead without changing the kinetic energy and strength of the hammerhead. The utilization rate of the hammerhead can be improved, and the influence of the structure on the heat treatment performance can be reduced, and the wear resistance of the hammerhead can be prevented from decreasing. Therefore, when we buy the machine, we can properly ask whether the hammer is cast by this method.

5. Rotating speed of the crusher rotor

Reasonable rotor speed can make the hammerhead of the crusher reach the best impact direction. If the speed is too low, when the material enters between the hammerheads of the crusher, it will cause serious wear on the side and root of the hammerhead of the crusher. If the rotation speed is too high, the material cannot enter between the radial hammerheads of the crusher, which will cause serious wear on the top of the hammerhead of the crusher. The correct wear part should be at the tangent line where the hammerhead of the crusher protrudes from the outside of the hammer handle.

In general, before purchasing a hammer crusher machine, it is necessary to examine the strength of the manufacturer, and secondly, pay attention to whether the hardness and water content of the material meets the hammer crusher's crushing. The Nile Machinery Co., Ltd. is a supplier specializing in mining machinery and equipment. It not only has its own factories in China but also has its own overseas warehouses in Kenya and Sudan. The products we produce are not only of good quality but also of good prices. Welcome to visit our factory.