Crushing equipment plays a vital role in the configuration of the construction sand and aggregate production line. The reasonable equipment configuration is related to the investment cost, production cost, and product quality of the entire production line. Cone crusher and impact crusher are commonly used crushing equipment in secondary crushing, so what is the difference between the two and how to choose? This article analyzes the difference between cone stone crusher and impact stone crusher from eight aspects

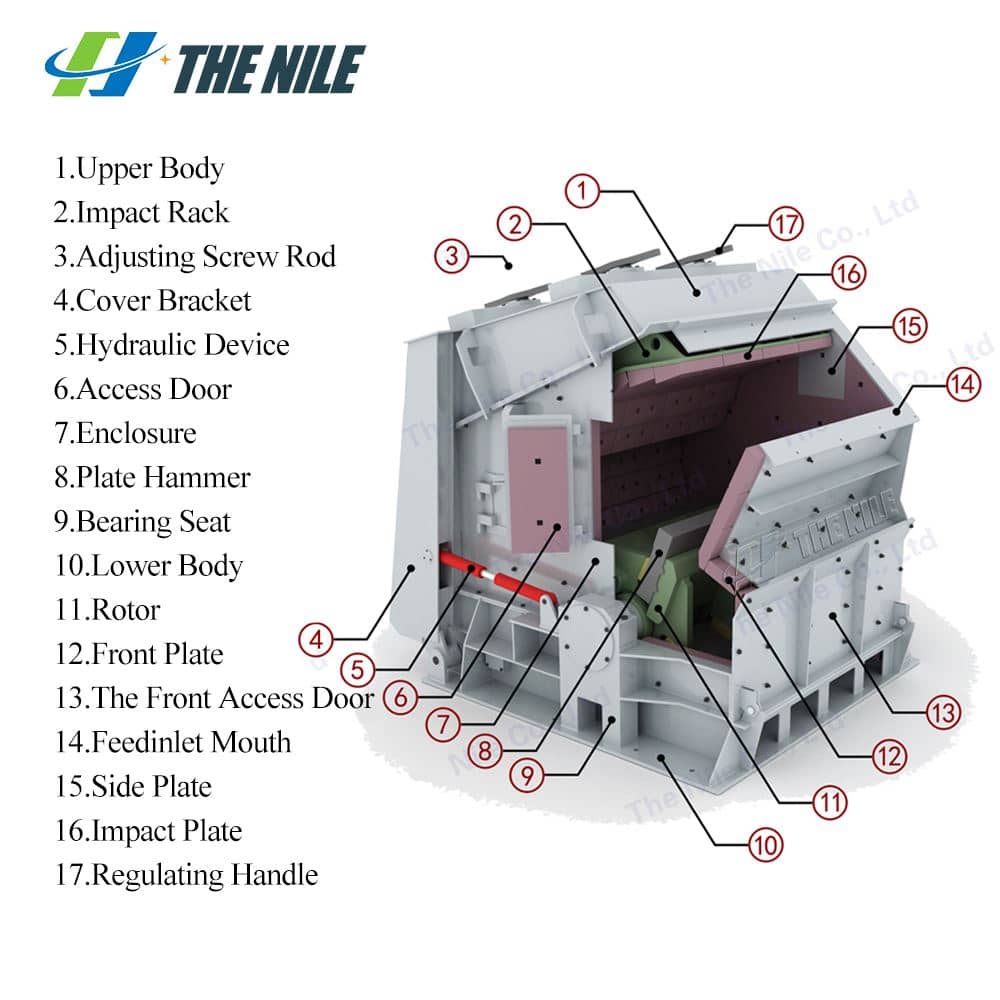

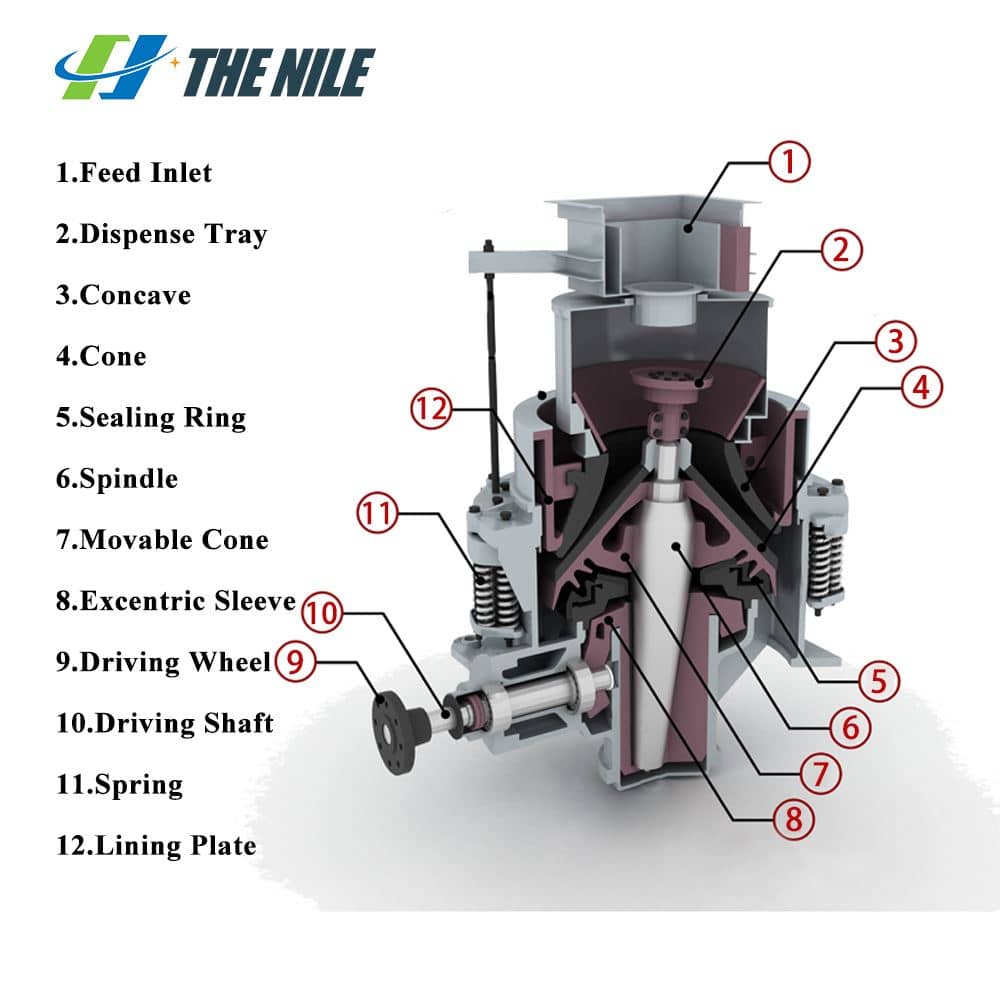

1. Different structure

The main components of the impact crusher equipment are spring, main shaft, blower, rotor frame, liner, and other parts. Cone crusher machine is mainly composed of frame, drive shaft, eccentric sleeve, spherical bearing, crushing cone, spring, and other parts. The appearance and structure of the two are obviously different, which is easy to distinguish.

2. The working principle is different

The impact crusher machinery adopts the principle of impact crushing. The material is repeatedly impacted and crushed between the plate hammer and the impact plate; the stone cone crusher uses a combination of extrusion, bending, and grinding to crush, so that the surface of the crushing wall is close to the surface of the rolling mortar wall. As a result, the material is continuously squeezed and bent, and broken in the annular crushing cavity.

3. Different scope of application

The cone crusher equipment mainly crushes some hard materials, such as granite, basalt, tuff, river pebble, etc; while the impact rock crusher mainly crushes the harder and brittle materials, such as limestone, etc.

4. Different discharging granularity

Cone rock crusher crushes finer materials than stone impact crusher. In the actual production process, cone crushers are commonly used in beneficiation technology, while impact stone crushers are commonly used in building materials and construction projects.

5. Different types of finished products

The impact crushing machine has a good grain shape, fewer edges and corners of the finished product, and more powder; the finished product of the cone stone crushing machine has more needle and flake grains. The cone crusher manufacturer of The Nile Company introduces advanced foreign technology, and the crushed product has a relatively uniform particle size and a cubic shape.

6. Different processing capacity

Compared with the impact stone crusher, the cone rock crushing machine has the characteristics of low energy consumption, large output, stable production, etc., so the cone crusher equipment is often used for large-scale and high-yield production lines operations.

7. Different input costs

The price of the cone crusher cost is more expensive than that of the impact price crusher, but its wearing parts have a longer life, so there is no need to replace it frequently to save costs. From a long-term perspective, cone crushers are more cost-effective than impact price crushing equipment. The initial purchase cost of the impact crusher machine is low, and the later maintenance cost is higher; the early stage cost of the cone stone crusher is high, and the later investment cost is lower.

8. Different pollution levels

The noise pollution and dust pollution of the impact rock crusher is relatively large, and the pollution of the cone stone crusher is relatively small.

Impact crushers and cone crushers have their own advantages and disadvantages. In the actual production process, we need to comprehensively consider the nature of the material, the size of the incoming and outgoing materials, and the output to select the appropriate crushing equipment. If you have any machine problems, welcome to consult The Nile Company for free, and we will arrange professional technicians to explain it to you.