Raymond mill machine is one of the commonly used grinding equipment, which is suitable for the high and fine milling processing of more than 280 kinds of materials in the mining, chemical, and construction industries. The performance of the mineral Raymond grinding mill is directly related to the output of the equipment and the quality of the finished product. So how can we improve the performance of the Raymond mill grinder machine?

1. Ensure Proper Material Humidity

High-pressure Raymond mill can be used to process materials with humidity below 6%. If the material has too high moisture content and is too humid, it will stick into a group during the grinding process, and some materials will even stick to the inside of the equipment, causing problems such as malfunction of the parts. Moist materials are likely to cause blockage when passing through the air duct, analyzer, and discharge port, resulting in difficulty in discharging or reduced output. Therefore, the humidity of the material must be controlled below 6% before entering the Raymond mill pulverizer for grinding.

2. Ensure Proper Material Hardness

Raymond milling machine can be used to process materials with Mohs hardness no more than 9.3. If the hardness of the material is too high, on the one hand, uneven grinding will appear in the grinding process, making the fineness of the finished product can not reach the specified standard. On the other hand, the over-hard material will make grinding difficult, which brings a lot of load to the grinding ring and roller and increase the wear of Raymond mill parts. Therefore, it is necessary to ensure that the hardness of the ground material is within the processing range of the stone Raymond roller mill.

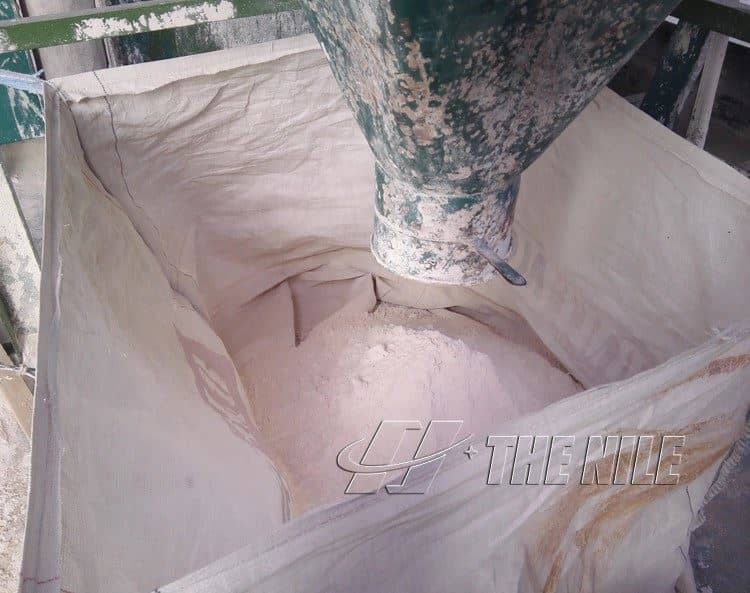

3. Ensure Fewer Impurities in Materials

The composition of the materials also affects the grinding effect and output of carbonate calcium Raymond Mill. Before grinding, the more fine powder contained in the material of Raymond powder grinding mill, the easier it is to adhere and affect the conveying and thus affecting the grinding. Therefore, materials with high fine powder content should be screened in advance.

4. Ensure Good Sealing Effect of the Machine

After the Raymond roller grinding mill is used for a long time, the sealing ring may be aged at the pipe joint. Therefore, it is necessary to check and maintain the machine regularly, replace the sealing ring when necessary, and adjust the powder locker during use to make the Raymond Mill powder machine keep sealed.

5. Repair or Replace the Wear Parts Regularly

The blade of the Raymond mill plant belongs to the wearing parts. During the continuous rotation of the blade, the shovel material is thrown between the grinding roller and the grinding ring for grinding, so there will be wear and tear when it is used for a long time. When the wear is serious, the blade will not be able to shovel materials, resulting in no powder or less powder. Long service time of grinding roller and ring will also cause wear and uneven surface, which will affect the performance of YGM series Raymond Mill. Therefore, it is necessary to pay attention to the wear condition of easily worn parts and repair or replace them in time.

6. Lubricate the Machine Well

After the high-efficiency Raymond mill works for a period of time, the bearings will be damaged due to oil cut-off or long-term lack of cleaning and maintenance, thereby reducing output. Therefore, it is necessary to regularly add lubricating oil to the lime Raymond grinding mill and carry out maintenance according to the equipment instructions.

As a well-known mining machinery and equipment manufacturer, Nile machinery has been committed to the research on the sieve passing rate, fineness, and production capacity of dolomite Raymond mill for many years. The sieving rate of the Raymond roller mill produced by Nile Machinery is up to 99%, and the fineness can be adjusted according to the demand. If you are interested in purchasing, feel free to consult customer service online for quotation details.