Both ball mills and raymond mills are commonly used in mining milling equipment. The following are their main differences in working principle, structure, and application.

1.Working principle

A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. Grinded materials are continuously given to the cylinder from the mouth and then crushed by the movement of the grinding media. Finally, the materials will be discharged by the strength of overflow and continuous ore feeding so as to move to the next step.

The working principle of Raymond Mill is that the rollers are rolled tightly in the grinding ring under the centrifugal force, material lifted by the shovel is ground into powder between the ring and roller, and then the fan blown up the powder through the analysis machine to the cyclone collector, powder achieve fineness requirements through the analysis machine, can not reach the requirements return to grinding cavity and continue grinding. The exhaust air is separated by industrial filter cloth to form a powder.

2.Structure

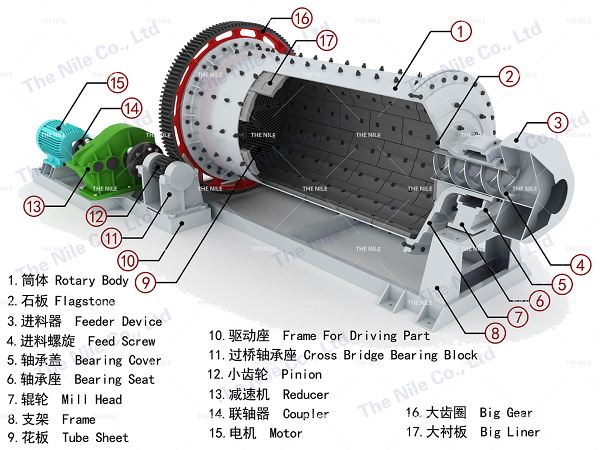

Ball Mill machine is composed of feeding part, discharging part, turning part, and driving part (reducer, small driving gear, electric motor, and electric control).

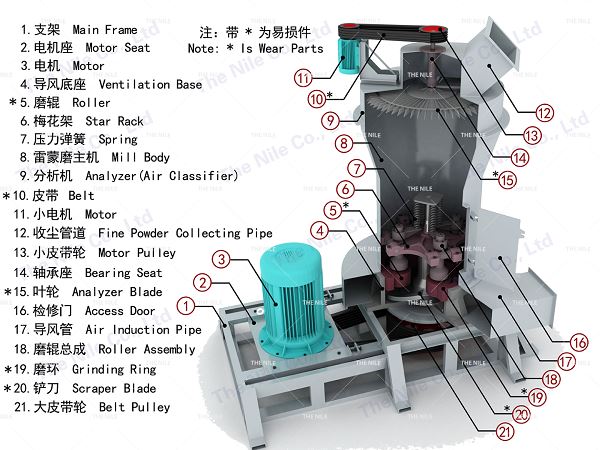

Raymond mill is mainly composed of main engine, analyzer, fan, finished cyclone separator, fine powder cyclone, and air duct. Among them, the main engine is composed of a grinding roller, a grinding ring, a frame, an inlet volute, a blade, and a cover.

(The structure of Ball Mill)

(The structure of Raymond Mill)

3. Application

Ball grinding mill is the main equipment for grinding materials after crushing. It is widely used in cement, silicate, fertilizer, ferrous metal, and non-ferrous metal, glass ceramics, etc. It can grind ores and other materials either wet or dry.

Raymond mill is commonly milling equipment mainly used in chemicals, building materials and other hundreds of kinds of materials of high fine milling processing, such as barite, calcite, potash feldspar, limestone, talc, white stone, gypsum, and other inflammable and explosive materials which hardness not greater than 9.3 moh's hardness, humidity is less than 6%. The discharge size can be adjustable from 40 to 400 meshes.

The Nile Machinery Co., Ltd. has nearly 33 years of production experience at ball mill & raymond mill, welcome to contact us for a detailed quotation.