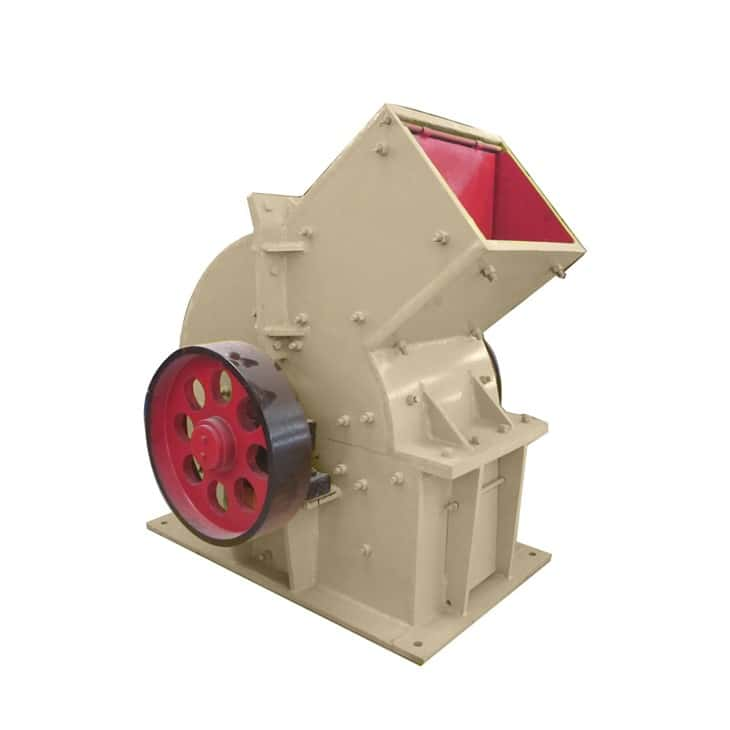

The hammer stone crusher is used to crush various medium-hard and weakly abrasive materials. The compressive strength of the material does not exceed 100MPa, and the moisture content is less than 15%.

Product introduction:

The hammer crusherequipmentis suitable for crushing medium-hard materials such as limestone, slag, coke, coal, and other materials in cement, chemical, electric power, metallurgy, and other industrial sectors. Hammerstonecrushers are also commonly used in crushing production lines, sand-making production lines, and beneficiation production lines in the mining industry.

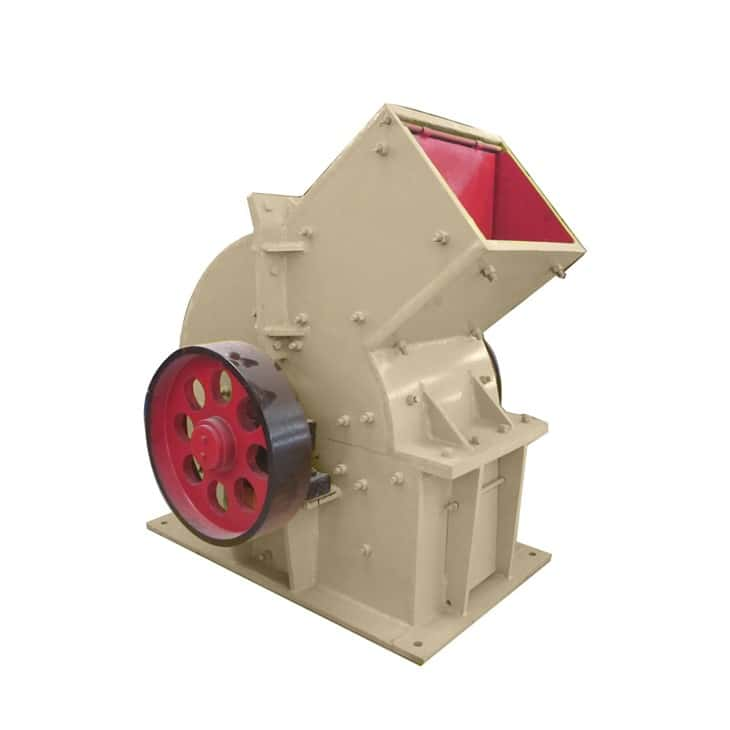

Working principle

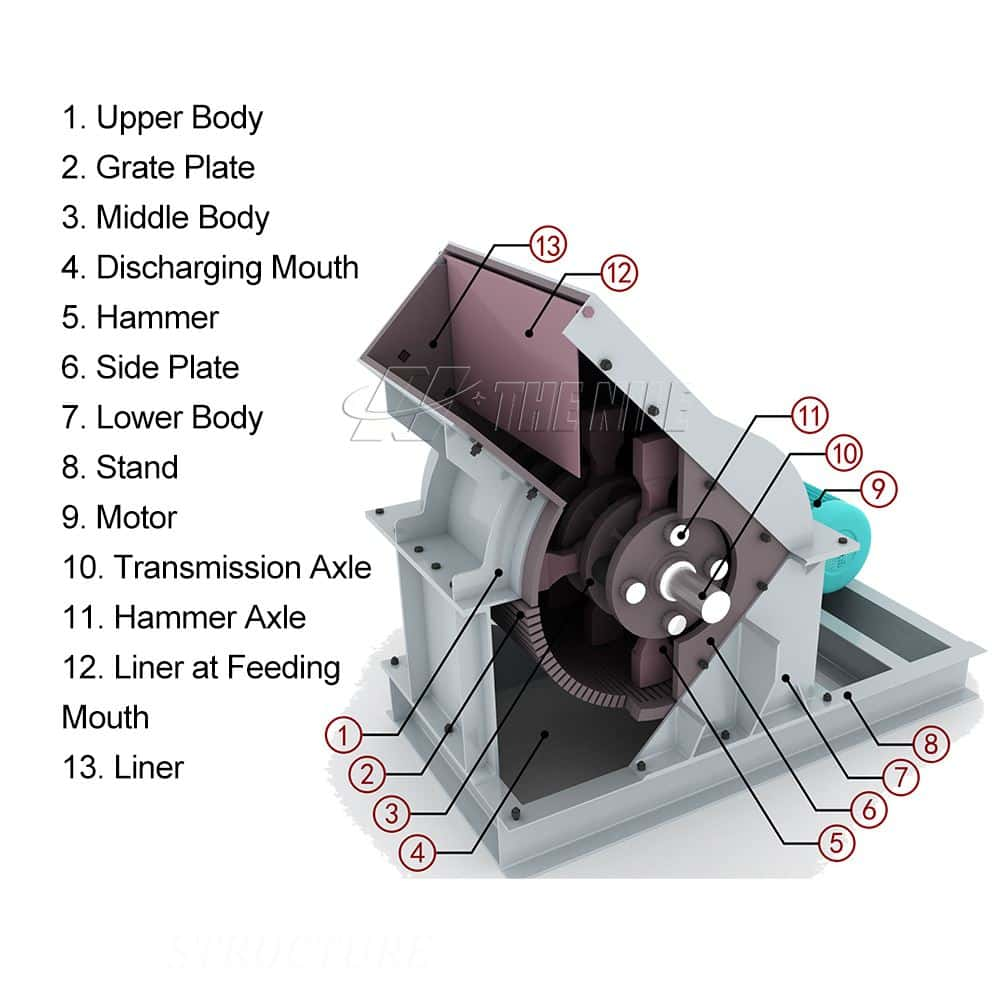

The hammer rock crusher mainly relies on impact energy to complete the crushing of materials. It is mainly composed of a box body, a rotor, a hammerhead, a counterattack liner, and a sieve plate. When working, the motor drives the rotor to rotate at a high speed, and the material evenly enters the crusher cavity. The high-speed rotating hammer impacts, shears, and tears the material and causes the material to be broken. At the same time, the gravity of the material causes the material to rotate from the high-speed hammer. The head rushes to the baffle and the screen bar in the frame, and the material larger than the screen hole size is retained on the screen plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size, and is discharged out of the machine through the screen plate.

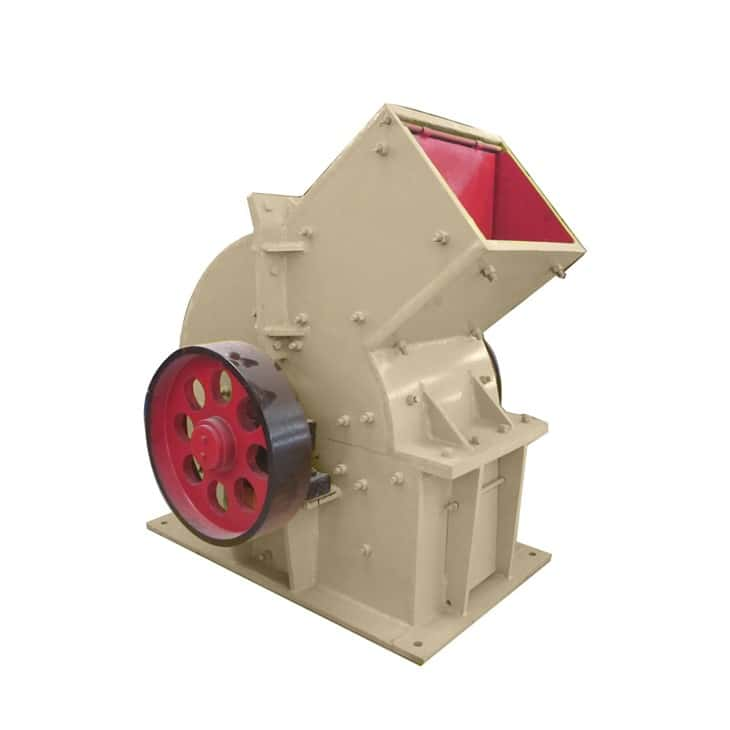

Product advantages:

1. It can work continuously with less downtime

The hammer crusherfunctionhas a long-running time, large crushing ratio, uniform product size, cubic shape, and no excessive crushing.

2. Large crushing ratio, the uniform finished product

Hammer crusher machine is suitable for crushing various medium hardness and brittle materials, such as limestone, coal, salt, gypsum, alum, brick, tile, coal gangue, etc. It is widely used in cement, coal preparation, power generation, building materials, chemical industry, metallurgy, etc. And other industries.

3. High economic benefits

The vulnerable parts of the hammer stone crushermachine are cast by a new process, with wear resistance, impact resistance, long service life, low component replacement cost, economical and reliability.

4. No dust leakage, environmental protection and safety

The structure of thestone crushing machineis sealed, which solves the problem of dust pollution and dust leakage in the crushing workshop.

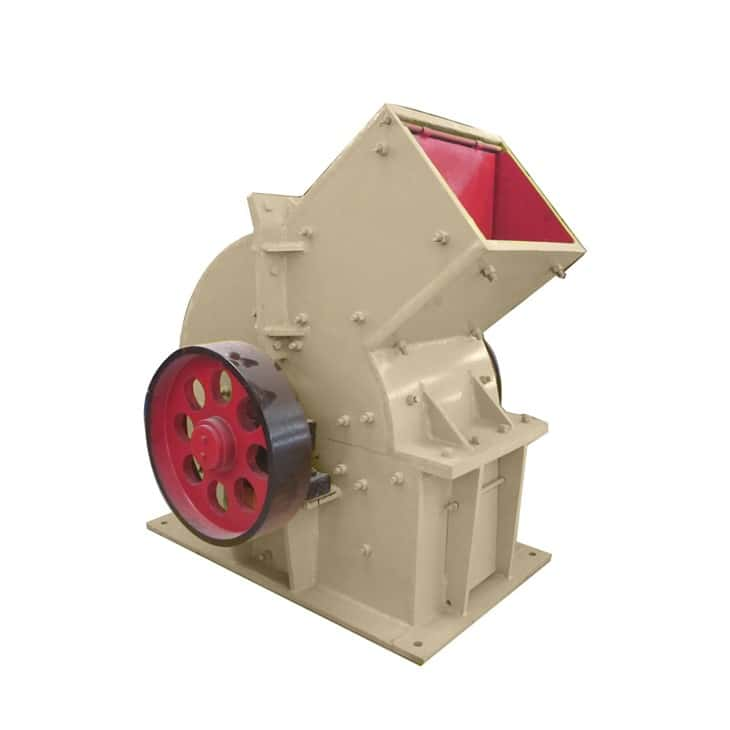

Operation and maintenance

(1) Before starting and stopping, get in touch with the upper and lower procedures related to the machine, and perform correct operations in the order of starting and stopping.

(2) To start the truck empty, pay attention to the material in the crushing cavity before stopping the machine.

(3) Regularly check all the anchor bolts and liner bolts of the equipment for any looseness. If they are loose, they should be tightened in time.

(4) Frequently check the usage of easily wearable parts such as hammers and liners. If any problems are found, they should be dealt with in time.

(5) Always check the lubrication situation and keep the lubrication system in good condition. The temperature of the rotor bearing should be kept below 60°C, and the maximum temperature should not exceed 70°C. If over-temperature is found, the cause should be found out and measures should be taken to eliminate it in time.

(6) Keep the feed evenly, and pay attention not to feed metal debris.

(7) Pay attention to check whether the discharge particle size meets the quality requirements, if not, replace the grate bar or adjust the grate bar bracket.

As a well-known hammer crusher manufacturer, The Nile's products have a good crushing effect and high work efficiency. Welcome to visit my factory, we will explain the production process and usage method of the product in detail for you.

| Model No. | Max. Feeding Size | Output Size | Capacity | Motor Power | Weight |

| (mm) | (mm) | (t/h) | (kW) | (t) | |

| PC 300*200 | ≤50 | ≤10 | 1-2 | 5.5 | 0.4 |

| PC400*300 | ≤100 | ≤10 | 5-10 | 11 | 0.8 |

| PC600*400 | ≤120 | ≤15 | 10-25 | 22 | 1.5 |

| PC800*600 | ≤120 | ≤15 | 20-35 | 55 | 3.1 |

| PC1000*800 | ≤200 | ≤13 | 20-40 | 75 | 7.9 |

| PC1000*1000 | ≤200 | ≤15 | 30-80 | 90 | 8.65 |

| PC1200*1000 | ≤250 | ≤19 | 80-200 | 132 | 13.6 |