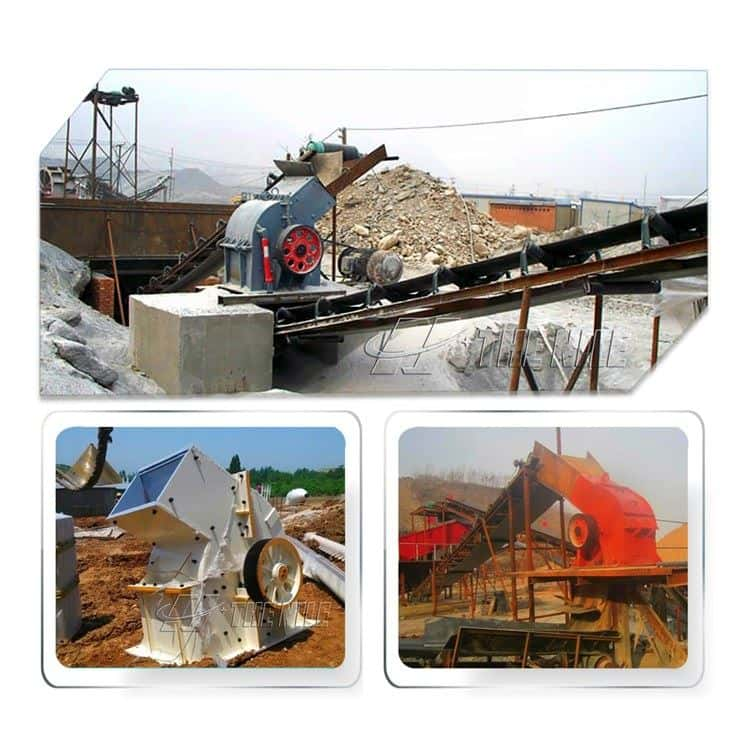

Applied Field: Mining stone hammer crusher, also known as hammer crusher, hammer crusher machine, etc., is one of the main crushing equipment for finely crushing limestone, coal, or other brittle materials below medium hardness in building materials, metallurgical, chemical and hydropower industries.

Introduction of Mining Stone Hammer Crusher

Mining stone hammer crusher has the advantages of simple structure, high crushing efficiency, large crushing ratio, strong production capacity, and uniform product granularity. There are many types of hammer crushers, such as large-scale and small-sized, which can be used in different fields. For example, a small-scale hammer crusher can be used for crushing raw materials in small factories, brick factories, and refractory factories.

Performance Characteristics and Advantages

1.Low investment, quick return on cost, large production capacity, high output, reliable performance, and can be shaped by one crushing with convenient maintenance and greatly reducing the production cost.

2.Large output, environmentally friendly and energy-saving, with n output of up to 1500 tons per hour by equipped with a hammer crushing production line. When crushing, add the appropriate amount of water to reduce dust pollution and protect the environment and workers' health.

3.The wear is small and the service life is long. The traditional grate bar is changed to control the discharge and reduce the wear of the hammerhead, which increases the service life of the hammerhead by 4-6 times.

4.With complete models and advanced technologies, the crushing capacity of a single unit mining stone hammer crusher can meet the different needs of customers by adopting the first patented technology.

Technical Parameters of Mining Stone Hammer Crusher

Model No. | Max. Feeding Size | Output Size | Capacity | Motor Power | Weight | Overall Diemension |

PC400*300 | 100 | ≤10 | 5-10 | 11 | 0.8 | 850*950* 880 |

PC600*400 | 120 | ≤15 | 10-25 | 18.5 | 1.5 | 1000*1000*1300 |

PC800*600 | 120 | ≤15 | 20-35 | 55 | 3.1 | 1515*2590*1040 |

PC1000*800 | 120 | ≤15 | 20-40 | 110 | 7.9 | 3200*2210*1515 |

PC1000*1000 | 120 | ≤15 | 30-80 | 132 | 8.65 | 3515*2230* 1515 |