Processing Materials: Fine rock crusher is suitable for crushing granite, basalt, cement clinker, quartz, iron ore, bauxite etc, especially for the fine crushing of pebbles and other raw materials overcomes the characteristics that traditional sand making equipment is only suitable for soft rock (below 150 MPa).

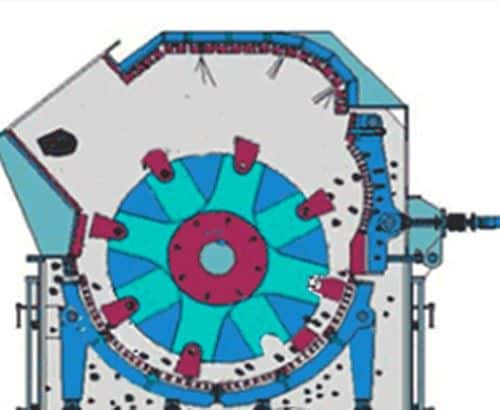

Structure of Fine Rock Crusher

The fine rock crusher is mainly composed of a rotating part, a guard plate part, and a box part. The wheel core of the rotary part has multiple non-overlapping hammer racks. The hammerhead is fixed on the hammer frame, and the width of the hammerhead is larger than that of the hammer frame and the wheel hub. The core is composed of several hubs, which are fixed on the main shaft. Both ends of the main shaft are supported on the frame with rolling bearing seats, and the guard plate is fixed on the box body in several pieces to protect the box body from abrasion and form different types of impact crushing cavities. The box body is divided into upper and lower parts, which are connected by bolts, which is convenient for disassembly and maintenance.

Working Principle of Fine Rock Crusher

The fine rock crusher is a continuous operation type of crushing equipment. The materials enter the cavity successively from the feeding port and fall on the high-speed rotating movable hammerhead. After the impact between the hammer and the impact plate, the material is initially crushed. After repeated hammering and impact with high frequency for many times, the material forms accumulation on the middle partition plate and then falls on the material throwing plate of the lower rotor with high-speed rotation, and then is thrown to the impact plate at high speed to enter into collision, fall, and then is forced to impact, crush and grind by mobile plate hammer. Finally, the material is subjected to multiple composite crushing, scouring, and grinding in the process of falling by its own weight to achieve the ultra-fine effect, and then discharged through the discharge port.

Technical Parameters of Fine Rock Crusher

Model | Feed Size | Output Size | Capacity | Motor Power | Rotor speed | Dimension |

800*400 | ≤120 | ≤10 | 30-40 | 37-45 | 860 | 2.1*1.4*1.7 |

800*600 | ≤180 | ≤10 | 40-50 | 45-55 | 860 | 2.1*1.62*1.7 |

800*800 | ≤180 | ≤10 | 50-70 | 45-55 | 860 | 2.1*1.84*1.96 |

1010*1010 | ≤180 | ≤10 | 60-75 | 55-75 | 720 | 2.1*1.84*1.96 |

1200*1000 | ≤180 | ≤10 | 100-110 | 90-110 | 590 | 2.45*1.6*1.96 |

1200*1200 | ≤180 | ≤10 | 120-150 | 110-132 | 590 | 3*2.16*2.5 |