The Nile STL series centrifugal concentrator STL Gold centrifugal concentrator processing plant is kind centrifugal concentration equipment. Centrifugal gold concentrator can be used not only for placer gold mining but also for hard rock mining to recover the natural gold and replacing amalgamation. In addition, it is also used to recover gold from the old tailing.

Technical Parameters

Model | Capacity | Power | Feed size | Slurry density | Backlash water quantity | Concentrates | Cone rotation speed | Water pressure | Weight |

STL-30 | 3-5 | 3 | 0-4 | 0-50 | 6-8 | 10-20 | 600 | 0.05 | 0.5 |

STL-60 | 15-30 | 7.5 | 0-5 | 0-50 | 15-30 | 30-40 | 460 | 0.16 | 1.3 |

STL-80 | 40-60 | 11 | 0-5 | 0-50 | 25-35 | 60-70 | 400 | 0.18 | 1.8 |

STL-100 | 80-100 | 18.5 | 0-6 | 0-50 | 50-70 | 70-80 | 360 | 0.2 | 2.8 |

Application ofCentrifugal Gold Concentrator

The application shows that the recovery rate of centrifugal gold concentrator can be as high as 90%, especially for the case in recovering the natural gold in lode ore with 65% of the ore having a milling size of 0. 074mm, the recovery for the natural gold is expected up to 98%,. For that natural gold of 0.004mm in particle size, the recovery is 97%. The cleaning upcycle is 1~4 hours, and the upgrade ratio is up to 1,000 times.

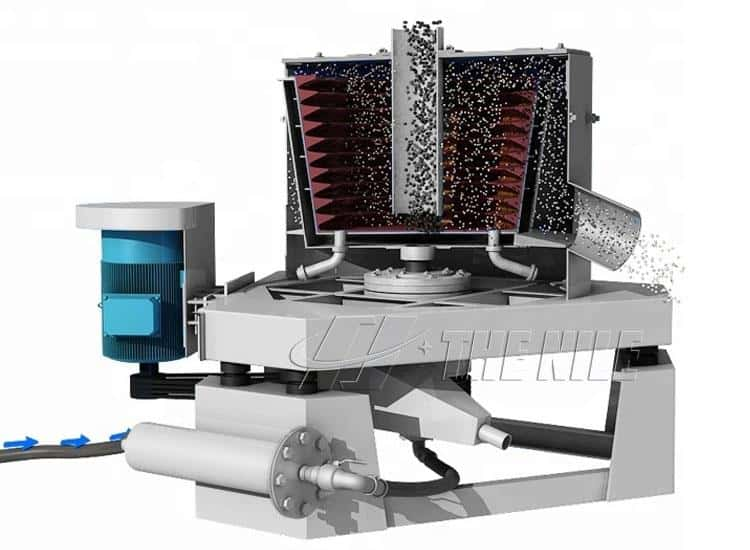

Working Principle ofCentrifugal Gold Concentrator

The main shaft of the centrifugal gold concentrator is a hollow shaft. The pressurize backwash water comes from the shaft, then goes into the separation unit, the water spray from the holes to the gratings. During the process, the pressure of the water shall be 0.06-0.15MPa. The slurry which is mixed with water, ore and sand will be injected to the mainframe. With the heavy centrifugal force, the slurry will be moved upward along the cone body, the light particles will be extracted from the upper part of the cone, then discharge through the tailing outlet. The materials with heavy particles will be staying in the gratings of the inner layer.

Features ofCentrifugal Gold Concentrator

1. High concentrating ratio and high recovery rate.

2. Total process automation, steady recovery performance.

4. Environmentally friendly ( no chemical additives or reagents).

5. Low water and electricity requirements.

6. Low production costs, durable wear parts, minimal maintenances requirements.

7. Compact design requiring less space, so easily merged into the existing mining processing.

8. Quick payback on investment, typically less than half-year.

Packing&Shipping

Standard package in export containers

FAQ

Q1: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each piece of equipment before delivery. We can provide services for product quality protection, on-time shipment protection, and payment protection.

Q2: How about the price?

A: We are manufactory, and we can give you a lower price than those trade companies. Besides, customers can get a discountduring promotion time.

Q3: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

←No more

Model | Capacity | Power | Feed size | Slurry density | Backlash water quantity | Concentrates | Cone rotation speed | Water pressure | Weight |

STL-30 | 3-5 | 3 | 0-4 | 0-50 | 6-8 | 10-20 | 600 | 0.05 | 0.5 |

STL-60 | 15-30 | 7.5 | 0-5 | 0-50 | 15-30 | 30-40 | 460 | 0.16 | 1.3 |

STL-80 | 40-60 | 11 | 0-5 | 0-50 | 25-35 | 60-70 | 400 | 0.18 | 1.8 |

STL-100 | 80-100 | 18.5 | 0-6 | 0-50 | 50-70 | 70-80 | 360 | 0.2 | 2.8 |