The gold centrifugal concentrator machine is a new type of gravity beneficiation equipment for beneficiating high-density minerals such as gold. A centrifuge is widely used for recycling, tungsten, tin, iron, and other sludge.

Product description:

The gold centrifugal concentrator machine is an efficient machine that can be used in mineral separators, gravity separators, and gravity separation process equipment. Not only can it be used for the mining of placer gold, but it can also be used to recover natural gold from hard rocks and recover gold from tailings.

The working principle of the centrifugal concentrator

The hollow shaft of the centrifugal gold concentrator can be driven by a belt through the motor drive part so that the rotating inner jacket rotates at a high speed to generate centrifugal force. The slurry enters the rotating inner sleeve through the feed pipe, and the slurry particles are separated under the action of the centrifugal force field. Heavy minerals remain in the guide trough of the rotating inner sleeve, and light minerals are discharged through the tailings launder. After a series of operations, the concentrate is discharged through the concentrate discharge outlet.

Features of centrifuge separator concentrator

1. The centrifugal ore recovery machine has a central discharge design, which can quickly and safely remove the concentrate.

2. Environmental protection and energy saving. The centrifugal gold separator machine has a small demand for water and electricity and does not need to add any chemical reagents during the working process.

3. Small footprint and easy installation. The centrifugal concentrator is small in size and is a full-line machine, only needs to be connected to a water pump and a water source.

4. Simple operation and high recovery efficiency. The centrifugal concentrator has a simple structure and high working efficiency, and the maximum processing capacity can reach 70 t/h.

5. Wear parts are durable and low maintenance cost.

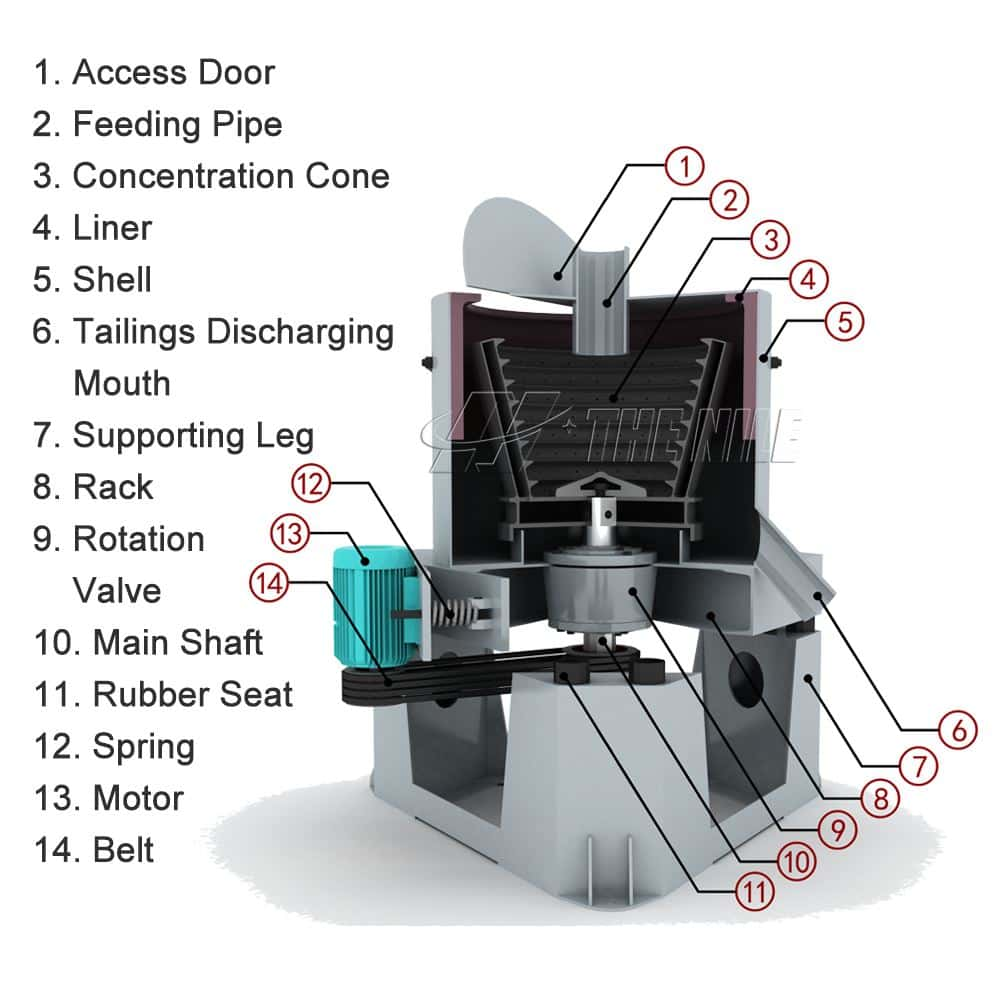

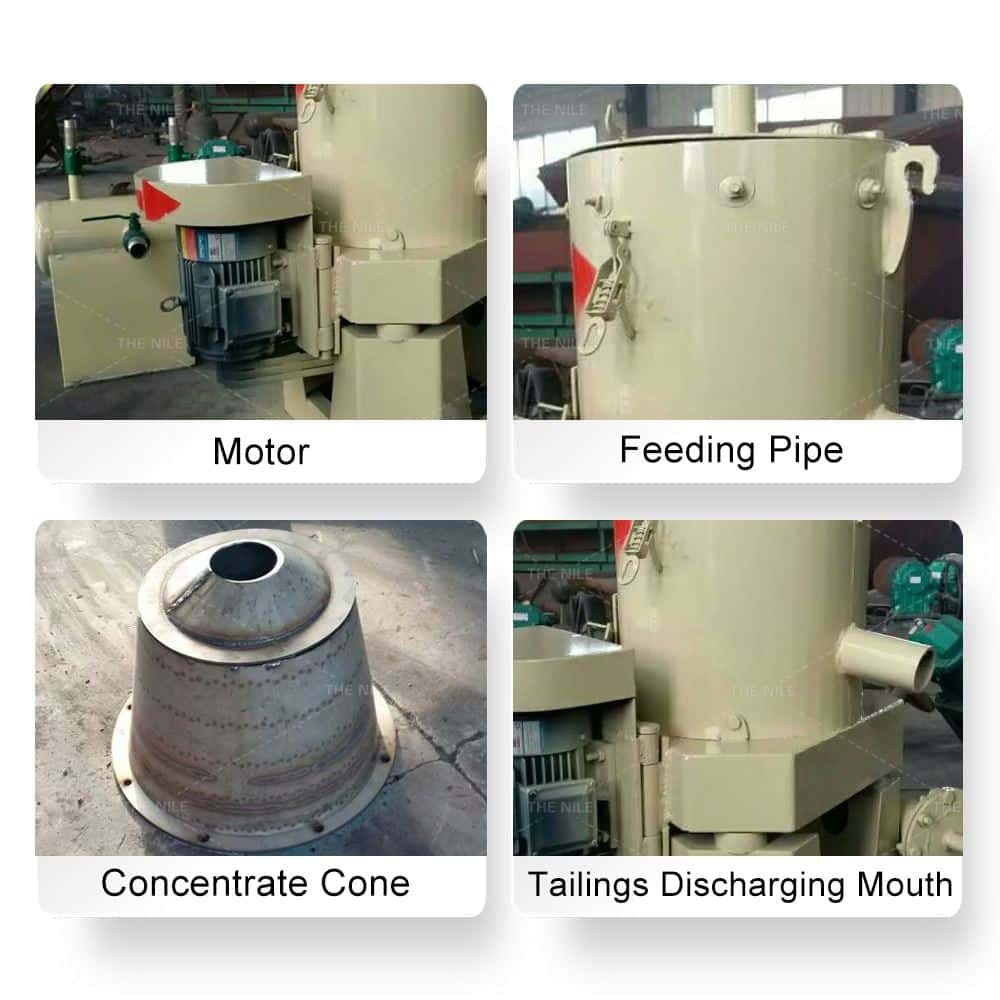

The structure of the centrifugal gold separator for sale

The centrifugal water-jacket gold separator is mainly composed of the feeding pipe, the tailings discharge port, the transmission shaft, the spring, the motor, the belt, the spring, and so on.

Packaging and shipping

Company strength

The Nile Machinery Equipment Co., Ltd. is a metallurgical machinery professional machinery factory that specializes in mining equipment research and development, manufacturing, sales, and provides professional mining processing plant workflow design, plant installation, equipment maintenance, and mineral processing technical guidance services. Our products are exported to Africa, Nigeria, Zambia, Zimbabwe, Uganda, Mozambique, South America, the Middle East, and many other countries and regions. At present, we have established our own overseas warehouses in Sudan and Kenya, and we also have our offices in most parts of Africa. You can observe the machinery up close and buy directly, saving transportation costs and time.

| Model | Capacity | Power | Feed size | Slurry density | Recoil water | Concentrates capacity | Water pressure | Weight |

| (t/h) | (kW) | (mm) | (%) | (m/h) | (kg/lot) | (mpa) | (t) | |

| STL-20 | 0.25-0.3 | 1.5 | <6 | <40 | 5-10 | 2-3 | 0.05 | 0.25 |

| STL-30 | 2-3 | 2.2 | <6 | <40 | 10-15 | 10-20 | 0.1-0.2 | 0.4 |

| STL-40 | 5-8 | 3 | <6 | <40 | 10-25 | 20-30 | 0.1-0.15 | 0.6 |

| STL-60 | 10-15 | 5.5 | <6 | <40 | 40-60 | 40-60 | 0.1-0.2 | 1.4 |

| STL-80 | 35-40 | 11 | <6 | <40 | 60-70 | 60-80 | 0.2-0.3 | 2.3 |

| STL-100 | 55-70 | 22 | <6 | <40 | 70-80 | 70-80 | 0.2-0.3 | 2.9 |