Products

Home > Products > Mineral Processing Equipment > Centrifugal Concentrator

Applied Field: Gold recovery centrifugal concentrator is an efficient machine that is used for mineral gravity separation process plant. It is most especially useful for recovering fine gold which gets lost during the operation of gravitational concentrators, which not only used for placer gold mining, but also can be used for the recovery of natural gold from rocks that are hard and recovering of gold from the tailings.

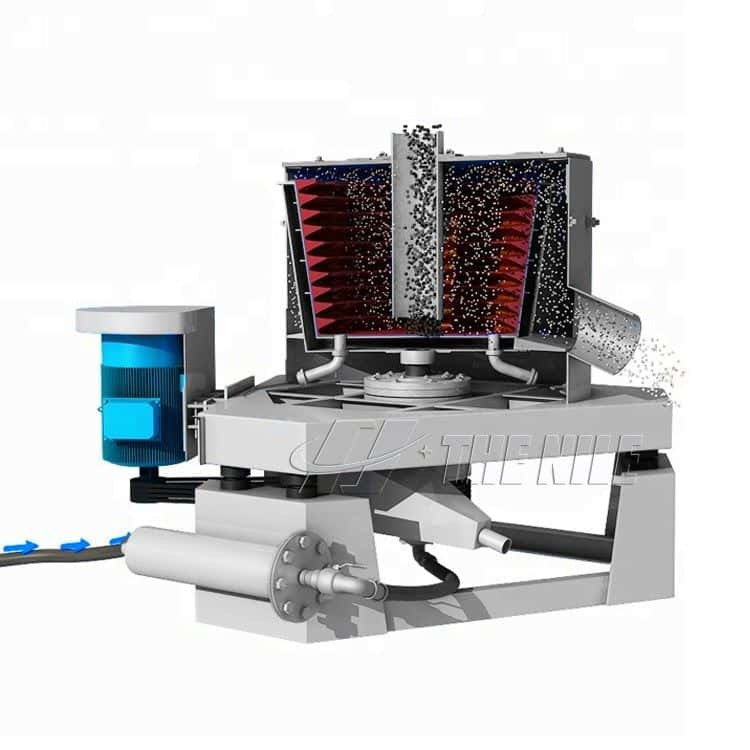

Introduction of Gold Recovery Centrifugal Concentrator

The gold recovery centrifugal concentrator is a new type of gravity concentration equipment for concentrating gold and other high-density minerals, which is used for roughing separation to recover most of the useful minerals.

The Advantages of Gold Recovery Centrifugal Concentrator

1.High concentrating ratio, high recovery, and low energy consumptions.

2.Total process automation with steady recovery performance.

3.Low water and electricity requirements, environmentally friendly(requires no chemical additives or reagents).

4.Low production costs, durable wear parts, and minimal maintenances requirements.

5.Compact design requiring less space, easy merged into the existing mining processing.

6.Quick payback on investment, which typically less than half a year.

7.Rugged design and a high degree of quality manufacturing ensures that every gold recovery centrifugal concentrator will provide many years of reliable, trouble-free operation in even the most severe operating environments.

Technical Parameters of Gold Recovery Centrifugal Concentrator

Model | Capacity | Power | Feed size | Slurry density | Backlash water quantity | Concentrates | Cone rotation speed | Water pressure | Weight |

STL-30 | 3-5 | 3 | 0-4 | 0-50 | 6-8 | 10-20 | 600 | 0.05 | 0.5 |

STL-60 | 15-30 | 7.5 | 0-5 | 0-50 | 15-30 | 30-40 | 460 | 0.16 | 1.3 |

STL-80 | 40-60 | 11 | 0-5 | 0-50 | 25-35 | 60-70 | 400 | 0.18 | 1.8 |

STL-100 | 80-100 | 18.5 | 0-6 | 0-50 | 50-70 | 70-80 | 360 | 0.2 | 2.8 |