Scope of application: Vibrating screen machine is suitable for coal, mining, metallurgy, building materials, electric power, water conservancy, light industry, and chemical industries.

Material: Vibrating screen machine is suitable for screening coal, limestone, crushed stone, gravel, metal or non-metallic ores, and other materials.

Product description

The circular vibrating screen has an elliptical vibration track, which is a multi-layer, high-efficiency new vibrating screen. The circular vibrating screen machine has a variety of screening specifications, up to four layers, and each layer has different functions. It is an indispensable high-efficiency screening equipment in the production line.

The working principle of industrial vibrating screen

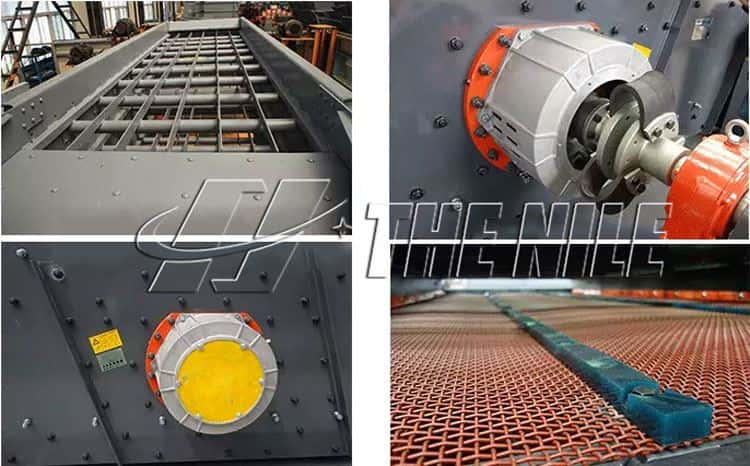

The vibrator is installed on the side plate of the screen box, and the eccentric block of the exciter is driven by a motor through a V-belt to rotate at a high speed, which generates a large centrifugal inertia force, which excites the screen box to produce a circular motion with a certain amplitude, and the material on the screen is inclined The screen surface of the screen is subjected to the impulse transmitted by the screen box to produce continuous throwing motion. When the material meets the screen surface, the particles smaller than the screen hole are passed through the screen to achieve classification.

Features of circular vibrating sieve

1. Strong excitation force. The exciter of the circular vibrating screen separators adopts the eccentric type, which not only increases the single excitation force of the eccentric mass of the exciter, but also the excitation force can be adjusted randomly, which is convenient for modular design and use.

2. The installation is simple, flexible, and convenient. The motor of the circular vibrating screen machine can be flexibly installed on the left or right side of the screen frame.

3. The sieve plate has a long service life. The sieve plate has a punching sieve plate and a rubber sieve plate. There are two types of single-layer and double-layer sieve plates, which can meet the requirements of high screening efficiency, long life, and no blocking of holes.

4. Stable operation. The vibrating circular screen adopts flexible connection such as cross shaft universal joint driveshaft or rubber coupling, so it runs smoothly

5. Convenient maintenance. The maintenance of the equipment is simple and convenient, the operation benefit of the whole machine is obvious and the structure is simple, which is beneficial to improve the manufacturing process level and assembly accuracy of the equipment.

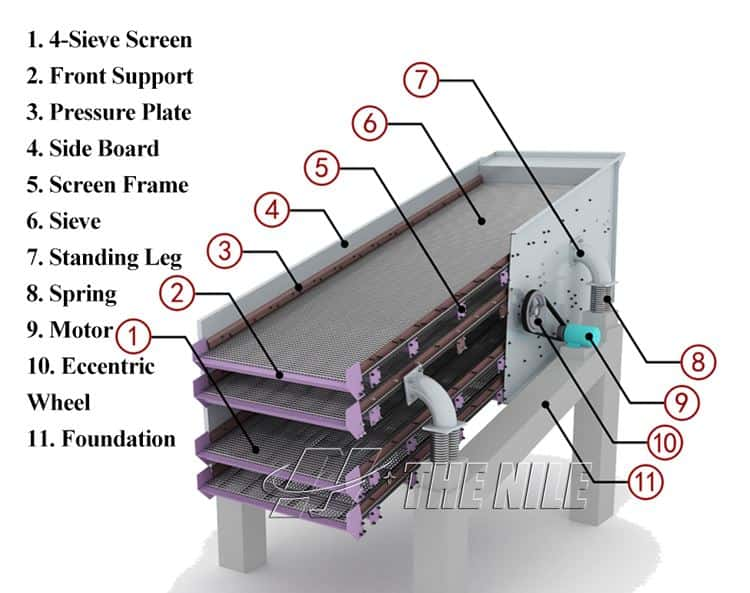

The structure of the circular vibrating screen for sale

YK series circular vibrating screen machine is mainly composed of a vibrator, screen box, screen, and damping spring. The side plate of the screen is made of a high-quality steel plate, and the side plate is connected with the beam and the base of the exciter with high-strength bolts or ring groove rivets. The cylinder-type eccentric shaft exciter and the offset block are used to adjust the amplitude.

Packaging and shipping

Company strength:

The Nile Machinery is an engineering general contracting comprehensive service company with mining machinery production and export as its main business. Since its establishment, it has built a large number of influential international projects and has been widely recognized by the country where it has served many countries and regions. At present, it operates various types of equipment such as stone crushing equipment, gold beneficiation equipment, sand making equipment, industrial grinding equipment, and mineral ore beneficiation equipment. The business areas cover metallurgy, mining, transportation, building materials, electric power, environmental protection, chemicals, etc.

Project cases:600 t/h limestone crushed stone production line

Material: Limestone

Output: 600 t/h

Configuration equipment: vibrating feeder, jaw crusher, impact crusher, high-efficiency fine crusher, vibrating screen, etc.

Client feedback

The crushed stone production line designed by The Nile has a high degree of automation. The complete production line requires almost no manual operation except for the startup and shutdown of the equipment and daily maintenance. In addition, the production line they configure has high production efficiency, and the finished stones have a uniform particle size, which brings us high profits. Looking forward to the next cooperation with The Nile!

| Model | Screen mesh | Layers | Max Feed size | Capacity | Screen Specification | Weight |

| (mm) | (mm) | (m³/h) | (mm) | (kg) | ||

| 2YK1237 | 2-50 | 2 | 200 | 25-50 | 1200×3700 | 4900 |

| 3YK1237 | 2-50 | 3 | 200 | 30-60 | 1200×3700 | 5200 |

| 4YK1237 | 2-50 | 4 | 200 | 30-60 | 1200×3700 | 5300 |

| 2YK1548 | 2-50 | 2 | 200 | 45-90 | 1500×4800 | 6300 |

| 3YK1548 | 2-50 | 3 | 200 | 45-90 | 1500×4800 | 6500 |

| 4YK1548 | 2-50 | 4 | 200 | 45-90 | 1500×4800 | 6600 |

| 2YK1848 | 2-50 | 2 | 200 | 55-110 | 1800×4500 | 6900 |

| 3YK1848 | 2-50 | 3 | 200 | 55-110 | 1800×4500 | 7200 |

| 4YK1848 | 2-50 | 4 | 200 | 55-110 | 1800×4500 | 7500 |

| 2YK1860 | 2-50 | 2 | 200 | 65-130 | 1800×6000 | 7100 |

| 3YK1860 | 2-50 | 3 | 200 | 65-130 | 1800×6000 | 7400 |

| 4YK1860 | 2-50 | 4 | 200 | 65-130 | 1800×6000 | 7700 |

| 2YK2160 | 2-50 | 2 | 200 | 80-160 | 2100×6000 | 11200 |

| 3YK2160 | 2-50 | 3 | 200 | 90-180 | 2100×6000 | 12400 |

| 4YK2160 | 2-50 | 4 | 200 | 90-180 | 2100×6000 | 15100 |

| 2YK2460 | 2-50 | 2 | 200 | 150-300 | 2400×6000 | 13500 |

| 3YK2460 | 2-50 | 3 | 200 | 180-360 | 2400×6000 | 13600 |

| 4YK2460 | 2-50 | 4 | 200 | 180-360 | 2400×6000 | 14400 |