Materials: Suitable for screening coal, limestone, crushed stone, gravel, metal or non-metal ore, and other materials.

Product Introduction:

The circular vibrating screen equipment has an elliptical vibration track, which is a multi-layer, high-efficiency new vibrating screen equipment. It is widely used in product classification in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry, and other industries.

Features of circular motion vibrating screen:

1. Simple structure and convenient maintenance

The Industrial screening equipment adopts a valve coupling, which is simple in structure, convenient to manufacture and maintain, and overcomes the defect of easy damage to the universal coupling.

2. Long service life

The vibrator of the circular vibrating screen machine adopts a block eccentric structure, which is simple in structure and can be matched with the selection of the feed box, which can increase the effective screening area of the vibrating screen machinery and prolong the service life of the screen at the feed end.

3. Long service life of the motor

The transmission part of the circular vibrating screen for sale adds an intermediate transition bearing seat. The application of the intermediate transition bearing seat effectively protects the motor and prolongs the service life of the motor.

The working principle of circular vibrating screen:

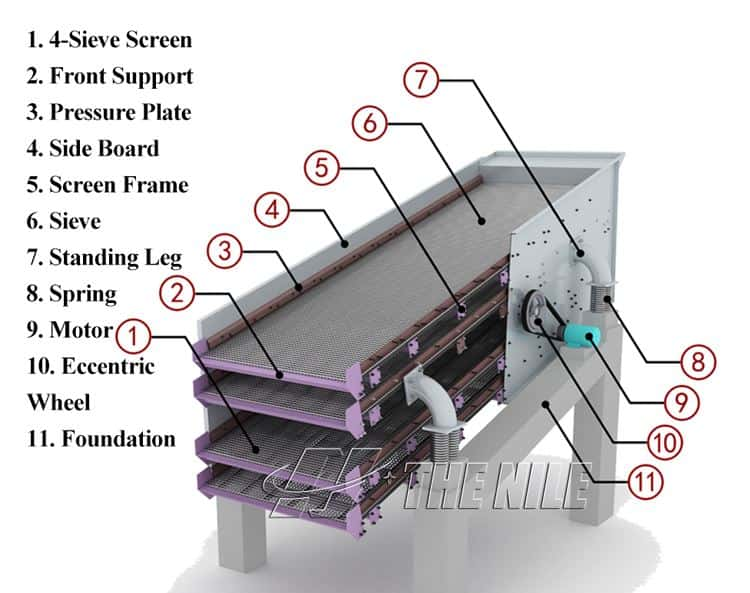

The circular motion vibrating screen equipment is mainly composed of a screen box, screen mesh, vibrator, and damping spring. The vibrator is installed on the side plate of the screen box and is driven to rotate by the motor through the coupling, generating centrifugal inertia force, forcing the screen box to vibrate.

FAQ:

Q1: Are you a factory or a trading company?

A1: We are a CE factory. We have factories in China and Kenya.

Q2: Where did your products have been exported to?

A2: Our products have been sold to South Asia, Africa, South America, the Middle East, etc.

Q3: How will you help customers install the equipment?

#1 Our senior engineers will provide online or on-site installation and training services.

#2 We have engineers in Uganda, Sudan, Kenya, and China, and we will provide 7*24 services.

Overseas service:

1. We have engineers in Kenya, Sudan, and Uganda, they will provide professional installation and training skills.

2. We have factories and warehouses in Kenya and China. When your wearing parts are damaged, you can go directly to the factory to buy them, which is convenient and quick.

3. Our products have been distributed all over China and exported to Europe, America, Asia, and African countries. Our sales managers and engineers know the local situation very well, and we will provide you with the most suitable solution.

| Model | Layers | Max Feed | Capacity | Screen Specification | Weight |

| Size | (m³/h) | (mm) | (kg) | ||

| (mm) | |||||

| 2YK1237 | 2 | 200 | 25-50 | 1200×3700 | 4900 |

| 3YK1237 | 3 | 200 | 30-60 | 1200×3700 | 5200 |

| 4YK1237 | 4 | 200 | 30-60 | 1200×3700 | 5300 |

| 2YK1548 | 2 | 200 | 45-90 | 1500×4800 | 6300 |

| 3YK1548 | 3 | 200 | 45-90 | 1500×4800 | 6500 |

| 4YK1548 | 4 | 200 | 45-90 | 1500×4800 | 6600 |

| 2YK1848 | 2 | 200 | 55-110 | 1800×4500 | 6900 |

| 3YK1848 | 3 | 200 | 55-110 | 1800×4500 | 7200 |

| 4YK1848 | 4 | 200 | 55-110 | 1800×4500 | 7500 |

| 2YK1860 | 2 | 200 | 65-130 | 1800×6000 | 7100 |

| 3YK1860 | 3 | 200 | 65-130 | 1800×6000 | 7400 |

| 4YK1860 | 4 | 200 | 65-130 | 1800×6000 | 7700 |

| 2YK2160 | 2 | 200 | 80-160 | 2100×6000 | 11200 |

| 3YK2160 | 3 | 200 | 90-180 | 2100×6000 | 12400 |

| 4YK2160 | 4 | 200 | 90-180 | 2100×6000 | 15100 |

| 2YK2460 | 2 | 200 | 150-300 | 2400×6000 | 13500 |

| 3YK2460 | 3 | 200 | 180-360 | 2400×6000 | 13600 |

| 4YK2460 | 4 | 200 | 180-360 | 2400×6000 | 14400 |