Material: Limestone

Output: 600 t/h

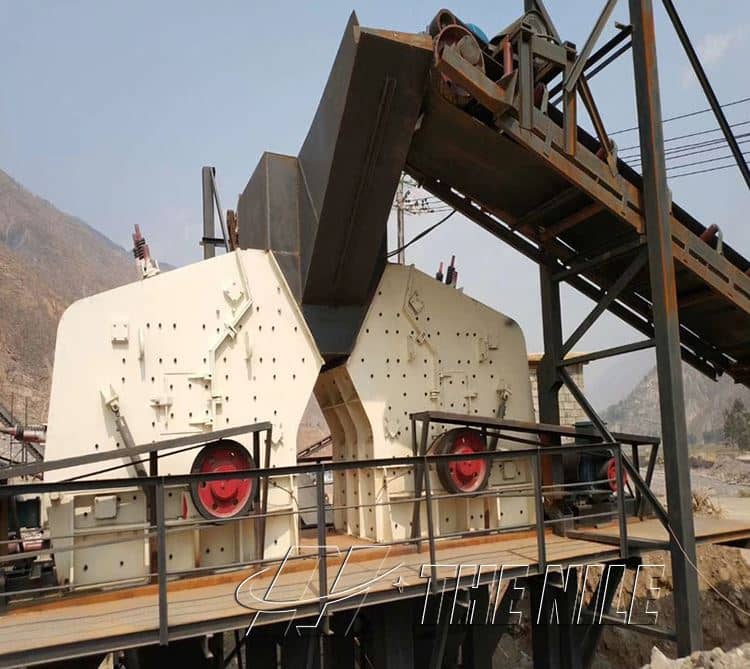

Configuration equipment: vibrating feeder, jaw crusher, impact crusher, high-efficiency fine crusher, vibrating screen, etc.

Recently, a mine owner from Sudan contacted the Nile for a list of the configuration of a limestone crushing production line with a capacity of 600 tons per hour. After understanding the customer’s needs, our technicians immediately carried out the location of the customer’s production site, weather conditions, and specific stone conditions. Through detailed investigation and understanding, we designed a reasonable and efficient limestone crushed stone production line for customers.

Finally, we configure vibrating feeders, jaw crushers, impact crushers, high-efficiency fine crushers, vibrating screens, and other conveyor equipment for customers. After the equipment trial operation, the after-sales personnel of The Nile specially came to the customer site to carefully check each piece of equipment and each process to confirm that the production line can meet the ideal requirements.

Customer feedback:

The crushed stone production line designed by the Nile has a high degree of automation. The complete production line requires almost no manual operation except for the startup and shutdown of the equipment and daily maintenance. In addition, the production line they configure has high production efficiency, and the finished stones have a uniform particle size, which brings us high profits. Looking forward to the next cooperation with the Nile!

Advantages of the production line:

1. Less personnel input: simple operation and a high degree of automation. The operation of the whole crushing production line requires people to feed materials to the silo and control switches, and maintenance personnel do not require too much manpower;

2. The feeding part adopts a vibrating screening feeder, and qualified materials are directly screened out, which reduces the load of the jaw crusher; the main crusher uses a jaw crusher and the second crusher uses a impact crusher. The crushing equipment works stably. The failure rate is low, the service life of wearing parts is long, the maintenance time is reduced, and the production efficiency is improved;

3. The equipment layout is compact, and the entire production line occupies a small area.